Production method for segregation-free iron-based mixed powder

A mixed powder and production method technology, which is applied in the production field of non-segregation iron-based mixed powder, can solve the problems of unstable size of pressed and sintered products, affecting the service life and stability of mechanical equipment, and large fluctuations in hardness, etc., to achieve reduction Segregation of dust and alloying elements, improved consistency, and improved fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1), ingredients

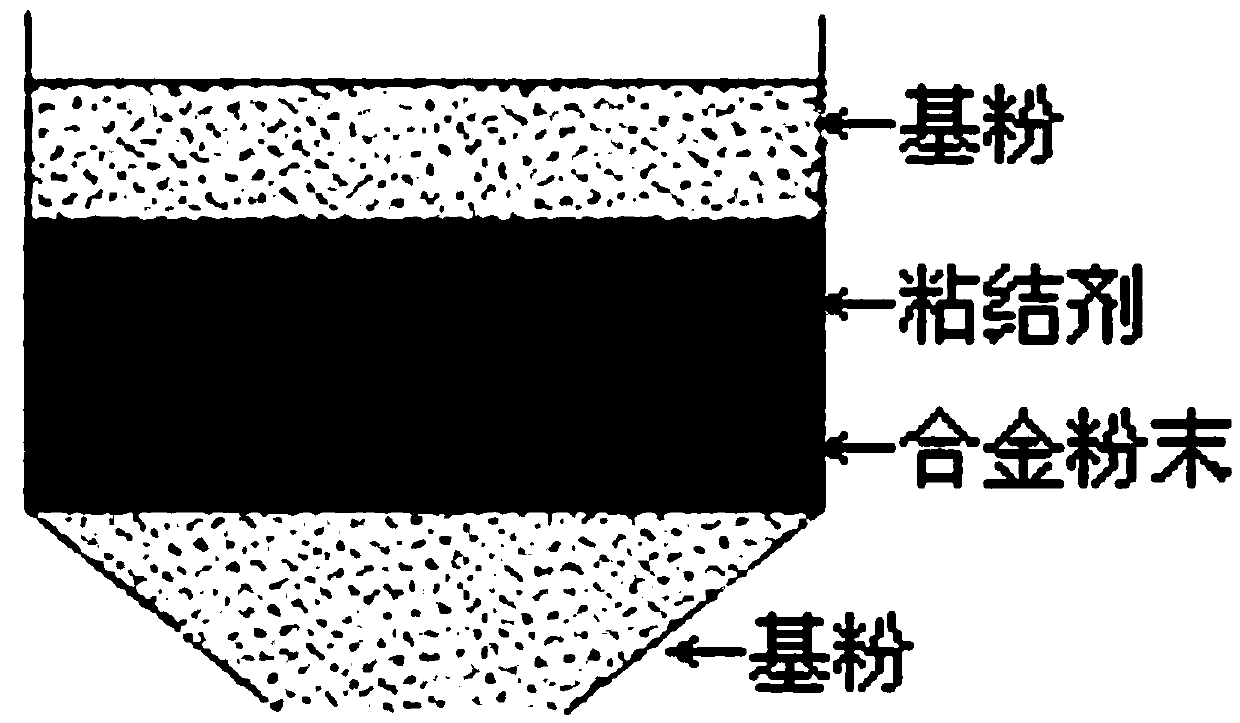

[0029] Such as figure 1 As shown, when batching, put the material into the hopper, first put part of the base powder into the hopper to form the bottom base powder layer, then add alloy powder into the hopper to form an alloy powder layer, add binder to the hopper to form a binder layer, Finally, add the remaining base powder in the funnel to form the uppermost base powder layer; For graphite powder with a total mass of 0.6%, the amount of copper powder added accounts for 1.8% of the total mass of the base powder; The amount accounts for 2 / 3 of the total mass of the base powder; (2), mixing

[0030] The material in the hopper is sent into a three-dimensional mixing mixer for mixing to obtain mixed powder. During mixing, the rotating speed of the three-dimensional mixing mixer is 25r / min, and the mixing time is 30min;

[0031] (3), screening

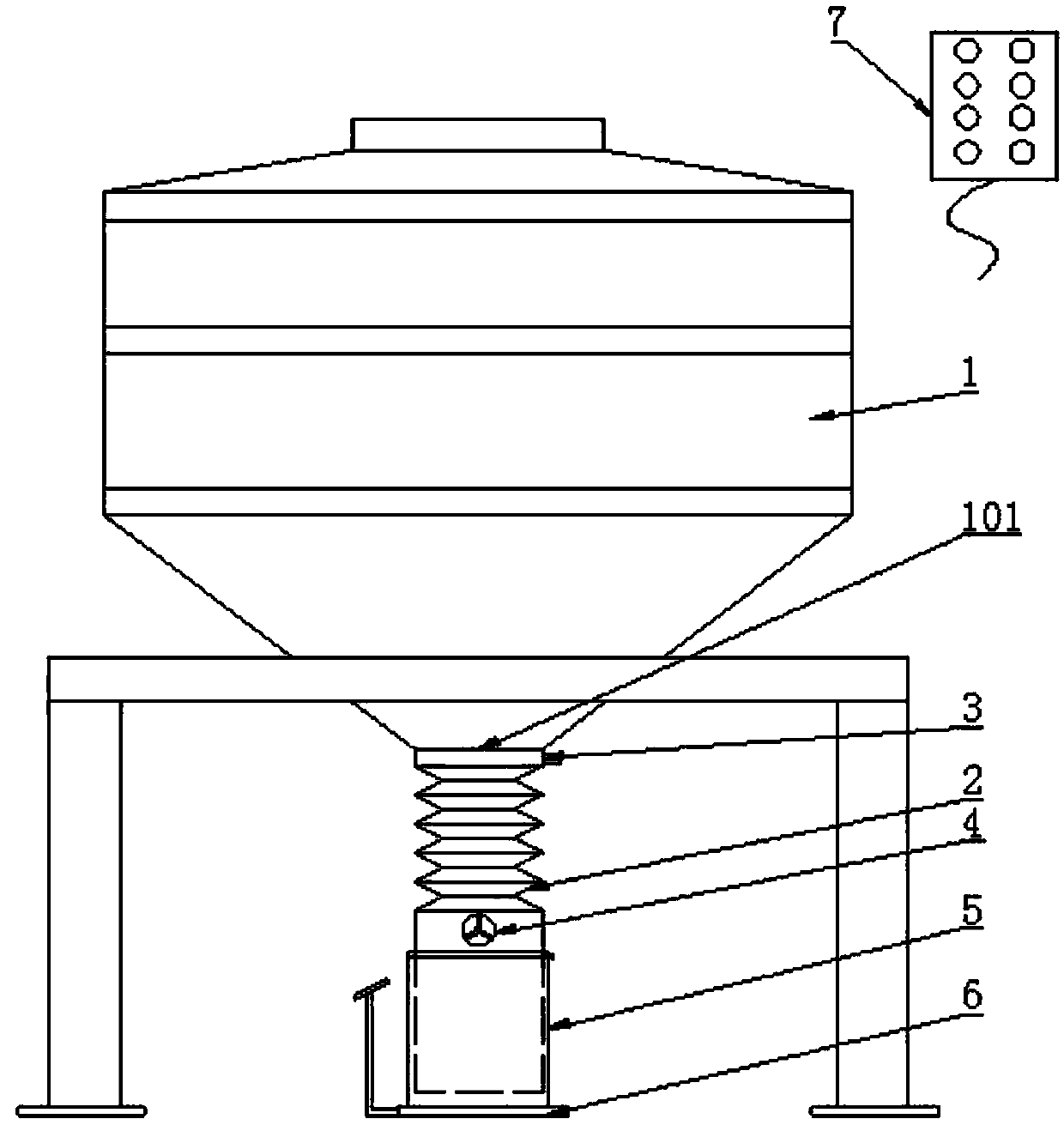

[0032] After the material is mixed by the mixer, it is fed into the high-frequency in-line sieve 1 through...

Embodiment 2

[0038] (1), ingredients

[0039] When batching, put the material into the hopper, first put part of the base powder into the hopper to form the bottom base powder layer, then add alloy powder into the hopper to form an alloy powder layer, add binder into the hopper to form a binder layer, and finally put into the hopper Add the remaining base powder to form the uppermost base powder layer; the base powder is iron powder, the alloy powder is copper powder, and the binder is paraffin powder accounting for 1.0% of the total mass of the base powder and 1.0% of the total mass of the base powder. 0.3% graphite powder, the addition of copper powder accounts for 2.5% of the total mass of the base powder; 2 / 3 of the total powder mass;

[0040] (2), mixing

[0041] The material in the hopper is sent into a three-dimensional mixing mixer for mixing to obtain mixed powder. During mixing, the rotating speed of the three-dimensional mixing mixer is 20r / min, and the mixing time is 40min; ...

Embodiment 3

[0047] (1), ingredients

[0048]When batching, put the material into the hopper, first put part of the base powder into the hopper to form the bottom base powder layer, then add alloy powder into the hopper to form an alloy powder layer, add binder into the hopper to form a binder layer, and finally put into the hopper Add the remaining base powder to form the uppermost base powder layer; the base powder is iron powder, the alloy powder is copper powder, and the binder is paraffin powder accounting for 0.8% of the total mass of the base powder and 0.8% of the total mass of the base powder. 0.4% graphite powder, the amount of copper powder added accounted for 2% of the total mass of the base powder; 2 / 3 of the total powder mass;

[0049] (2), mixing

[0050] The material in the hopper is sent into a three-dimensional mixing mixer for mixing to obtain mixed powder. During mixing, the rotating speed of the three-dimensional mixing mixer is 20r / min, and the mixing time is 40min;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com