Electric tilting hinge for intelligent slope roof window

A technology for flipping hinges and sloping roofs, which is applied to roofs, door/window accessories, and power control mechanisms. It can solve problems such as complex structures, inability to achieve internal wiping of outer glass, and limited opening of window sash, and achieve obvious economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

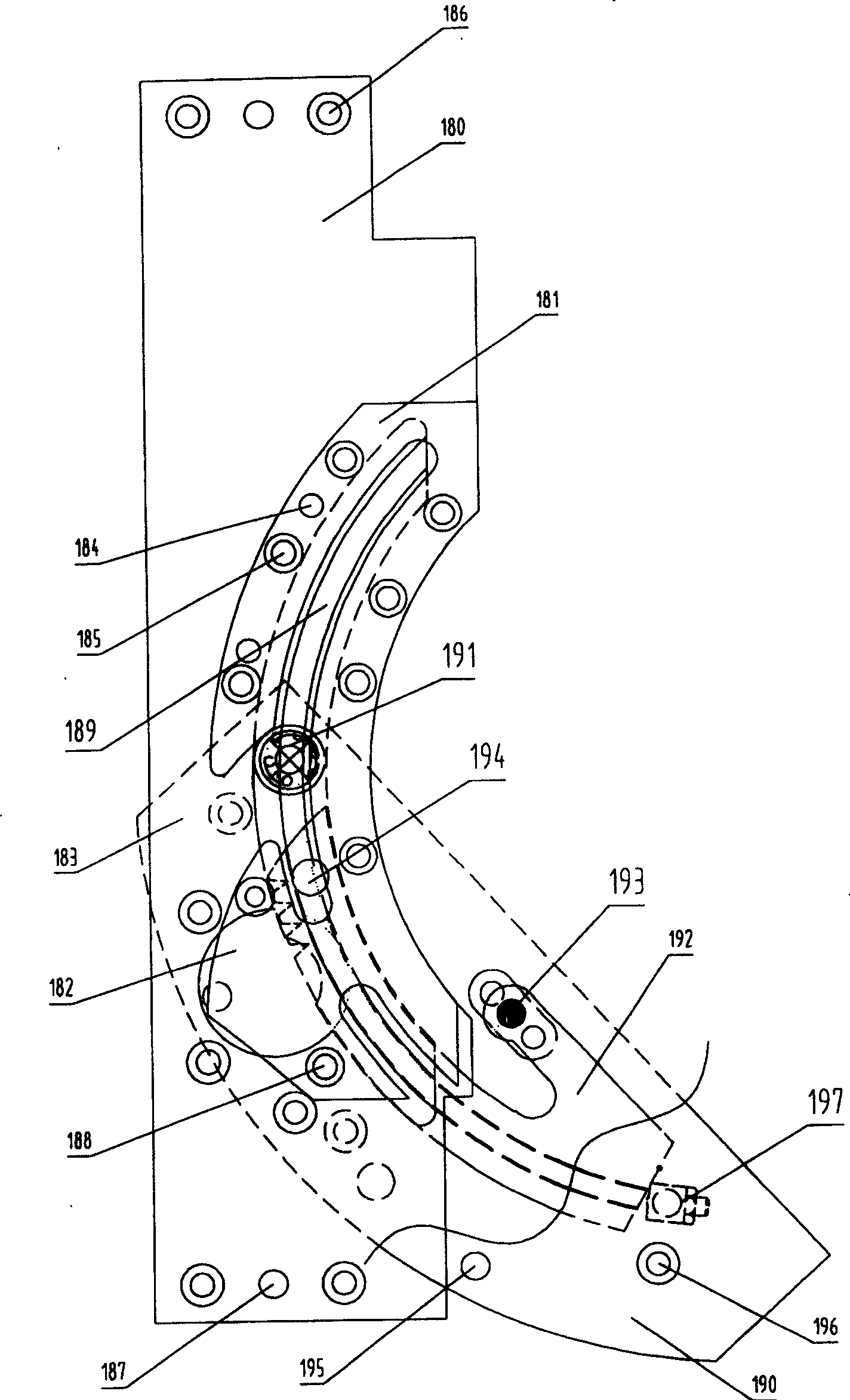

[0012] combined with figure 1 The details are as follows:

[0013] The intelligent sloping roof window electric flip hinge includes a window frame hinge fixing plate 180 fixed on the window frame, a window sash hinge fixing plate 190 fixed on the window sash, and a rotating structural part connecting the two.

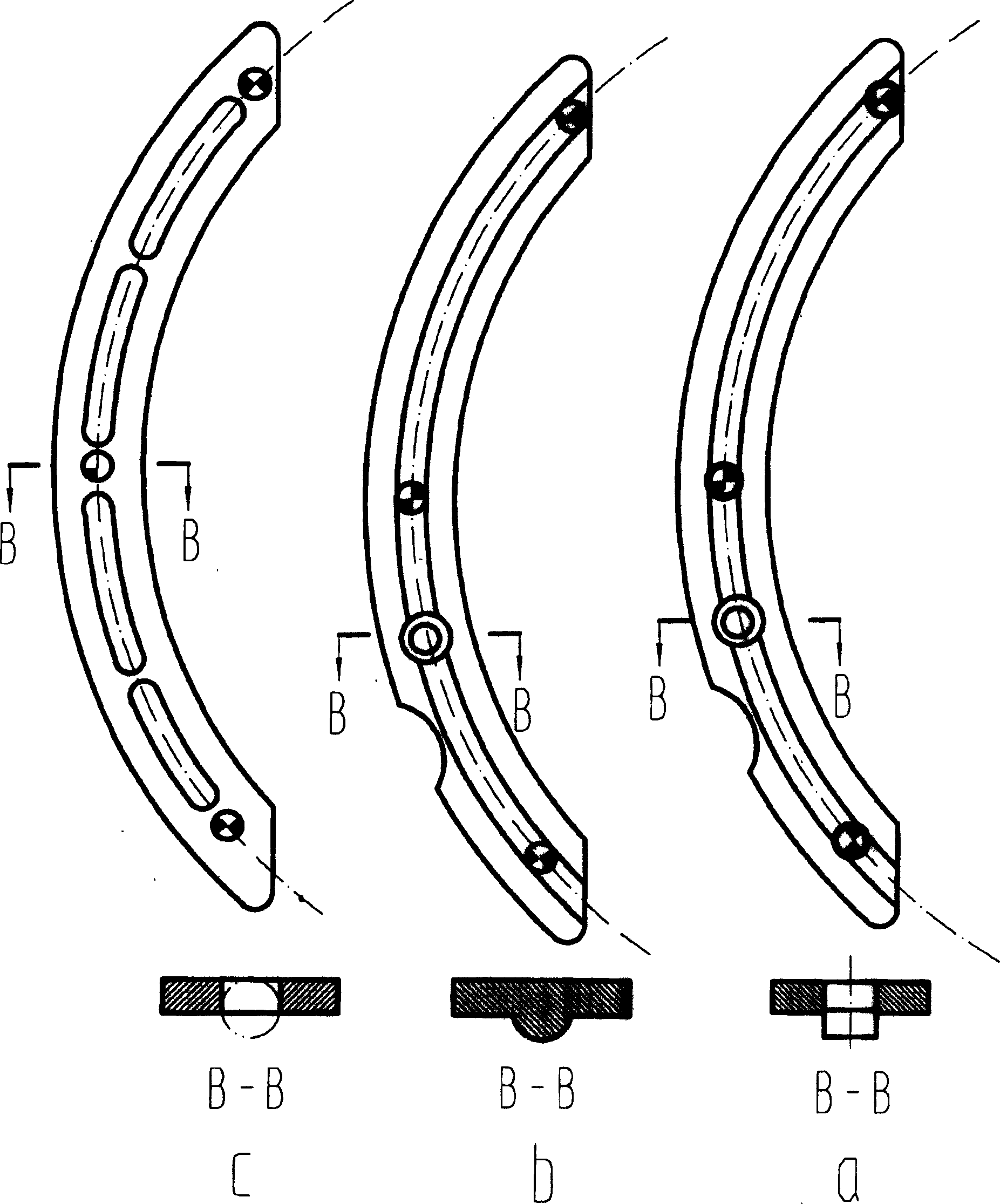

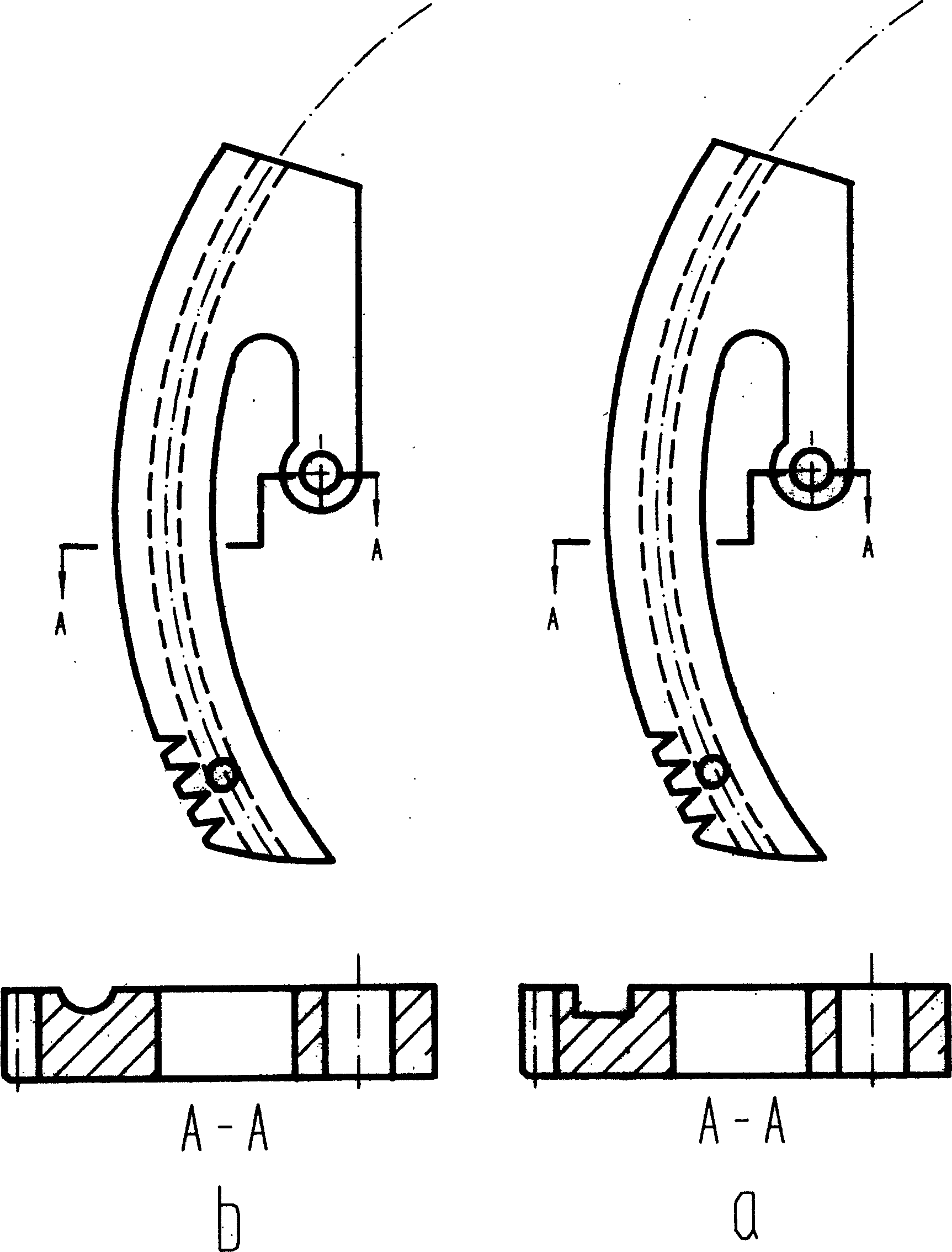

[0014] Window frame hinge fixing plate 180 and hinge frame 181 are provided with supporting blocks in the middle, and the two are fastened and connected by pins. Rack slide rail 189 is fixed on the window frame hinge fixing plate 180 and corresponds to the rack chamber of the hinge frame. There is a convex groove on the slide rail, which can be matched with the groove on the arc rack. The reducer is installed in the reducer mounting hole 182 and fastened by the reducer mounting screw 188 to form an electric hinge for the window frame. The fixed leaf is accurately contained in the window frame inner surface where the window frame and the window sash are connected throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com