Whirlwind barrel for dust collector

A cyclone and vacuum cleaner technology, applied in suction filters and other directions, can solve the problems of dust escape, reduce the dust removal efficiency of the cyclone cylinder, and achieve the effect of improving the dust removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

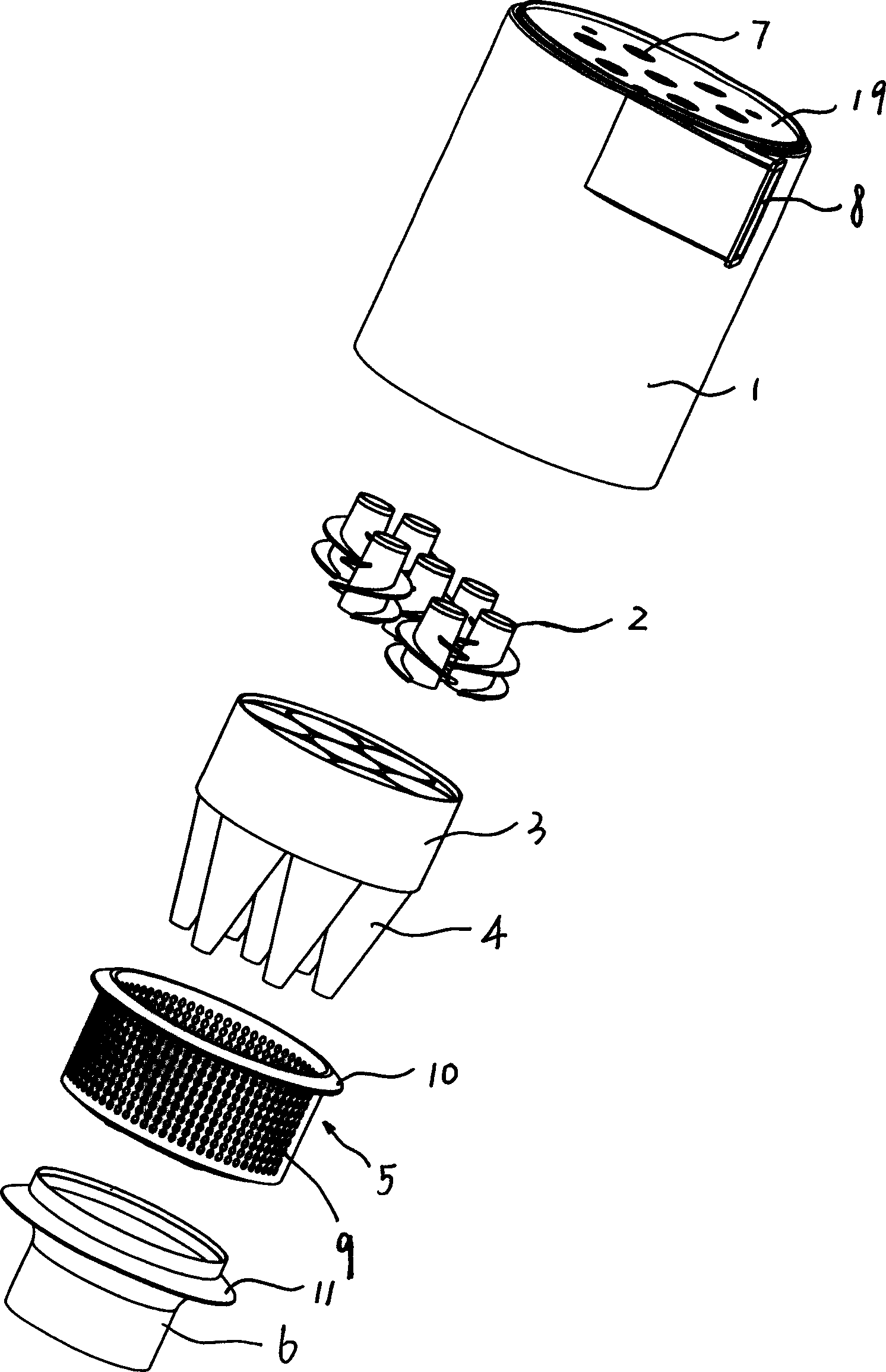

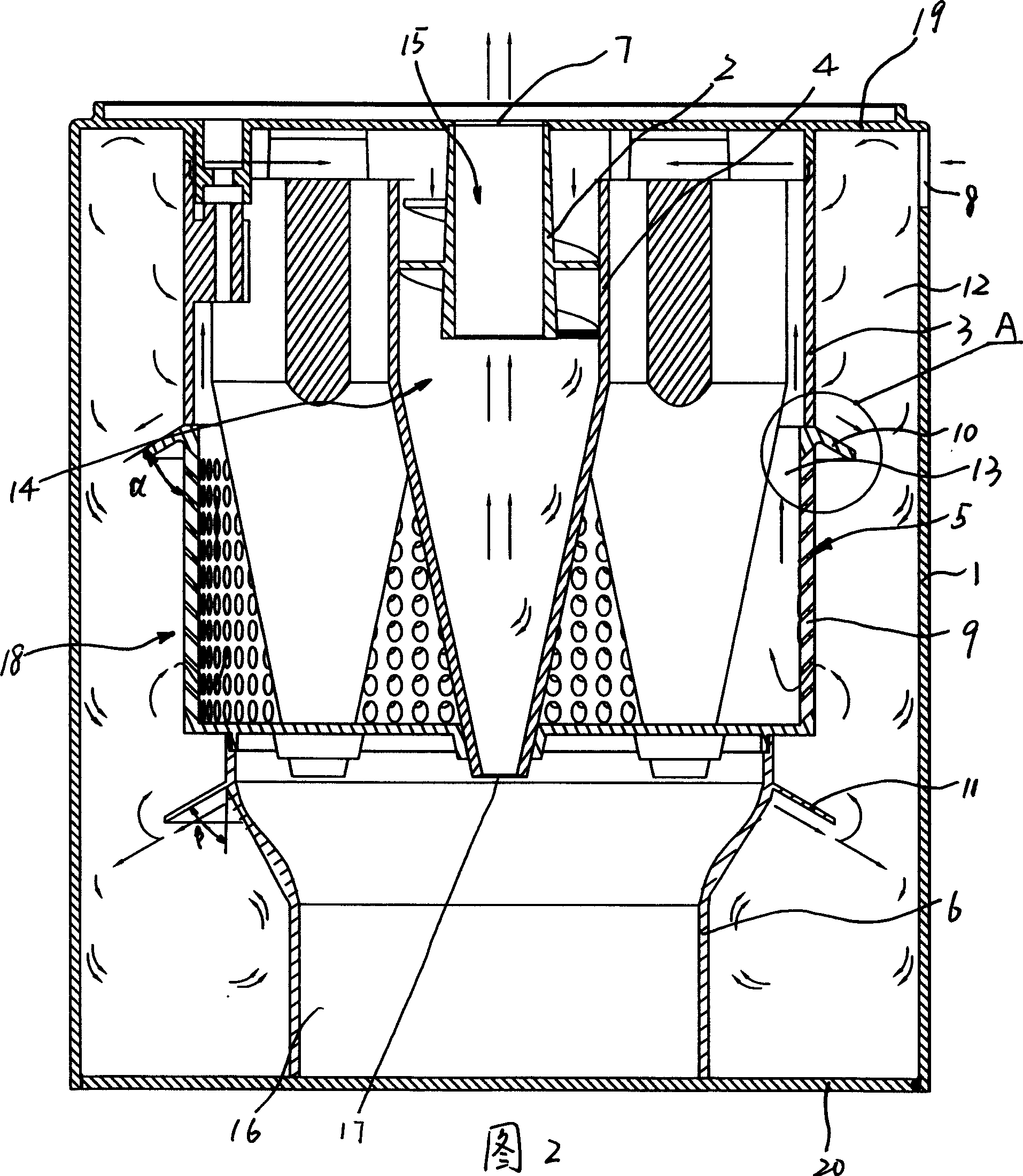

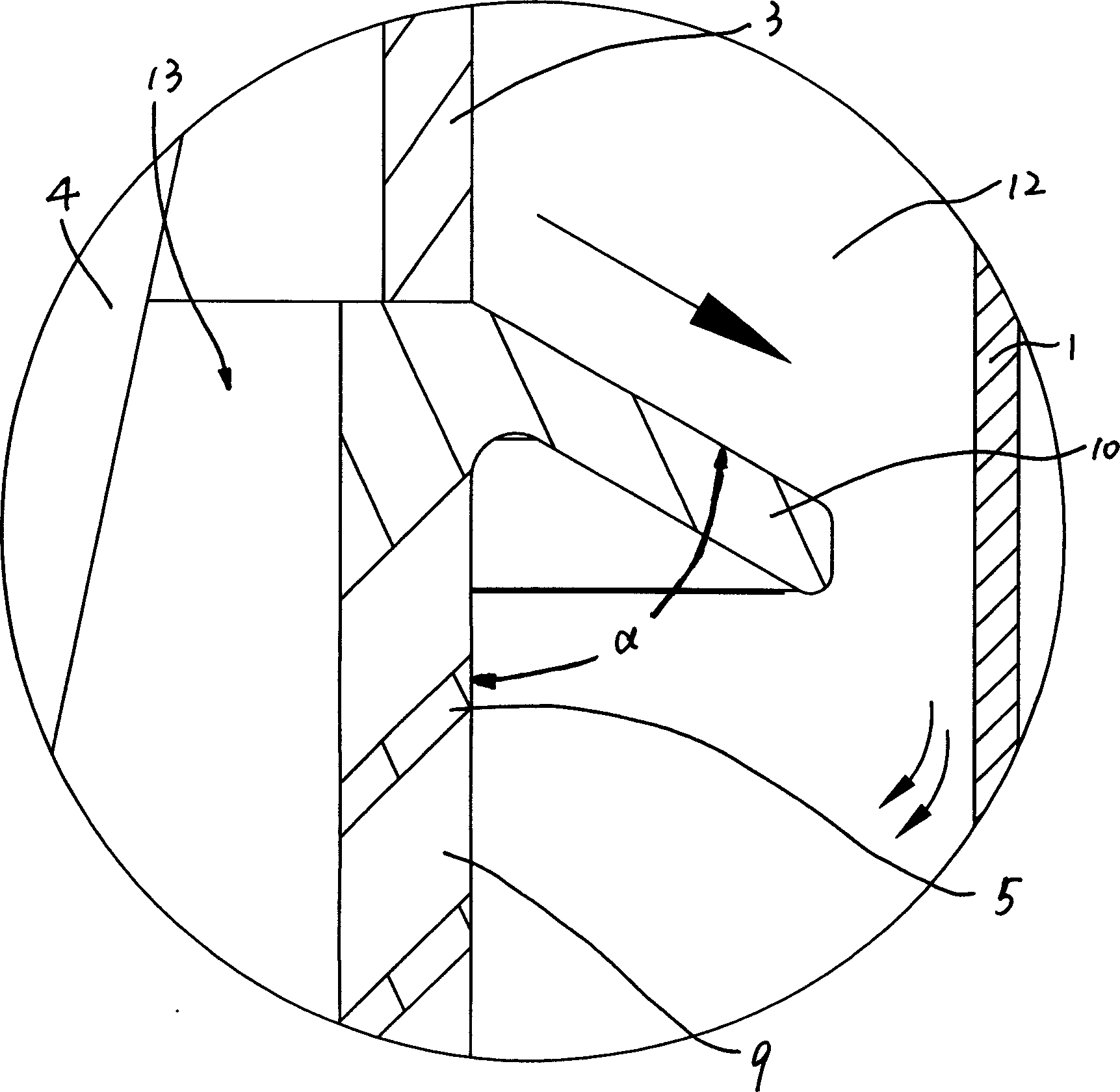

[0010] See attached figure 1 - Accompanying drawing 3, a cyclone cylinder of a vacuum cleaner, comprising a cylinder 1 having an air inlet 8, and a guide tube 18 coaxially arranged in the cylinder 1, the guide tube 18 and the A dust separation chamber 12 is formed between the cylinders 1. The top of the dust separation chamber 12 has a top cover 19 arranged between the cylinder 1 and the draft tube 18. The bottom of the dust separation chamber 12 has a top cover arranged on the cylinder 1. The bottom cover 20 between the guide pipe 18 and the dust separation chamber 12 communicate with the air inlet 8 . The draft tube 18 includes the upper draft tube body 3, the lower inner dust tube 6, and the air intake mesh cover 5 between the draft tube body 3 and the inner dust tube 6. In the present invention In the embodiments shown in the accompanying drawings, the draft duct body 3, the inner dust cylinder 6, and the air intake mesh cover 5 are three independent parts, wherein the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com