Electric controlled type vehicular magnetic power driven brake

A magnetic braking, electronically controlled technology, applied in the deceleration device of DC motor, electric motor/converter plug, brake actuator, etc., can solve the problems of tire lock, unstable braking, low energy conversion efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

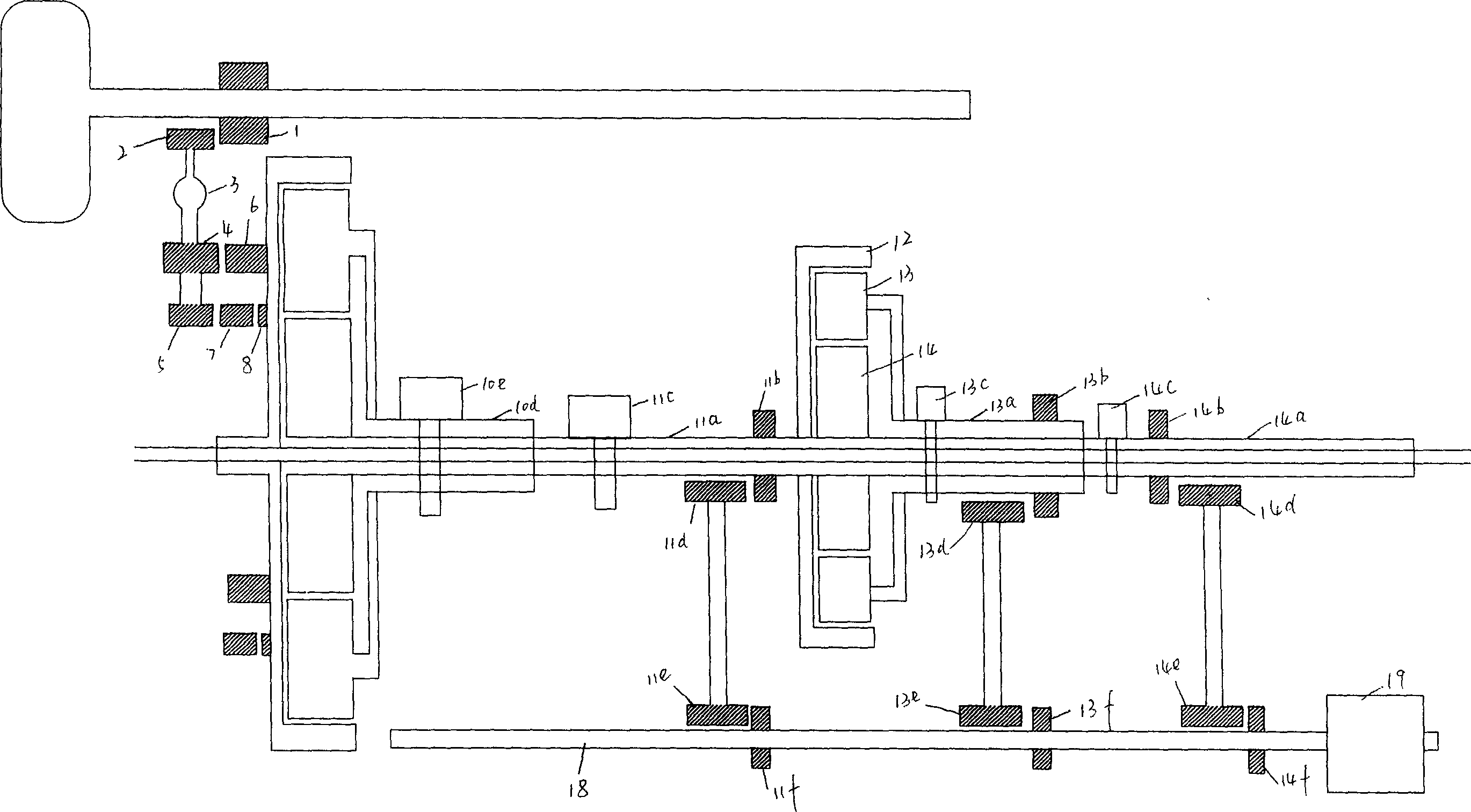

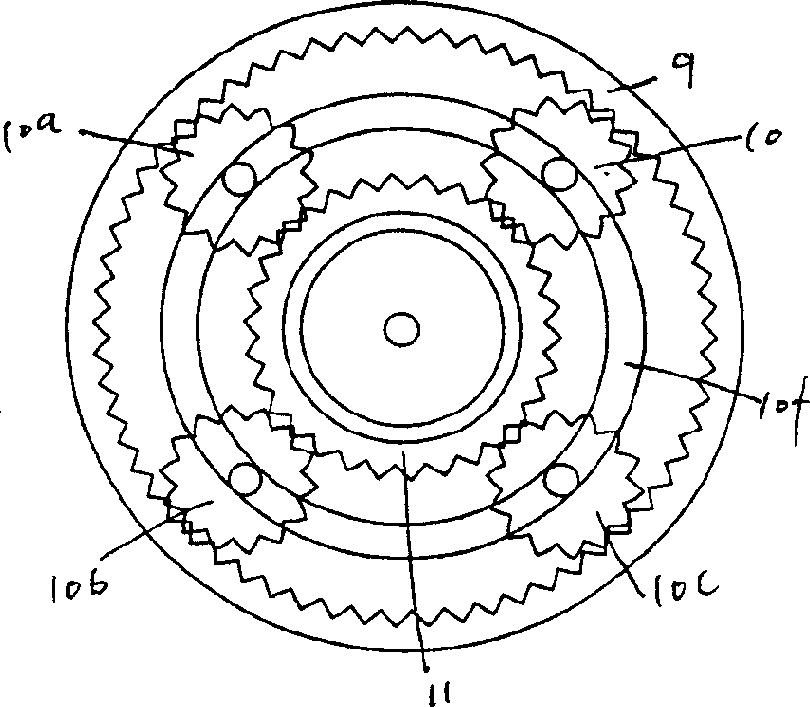

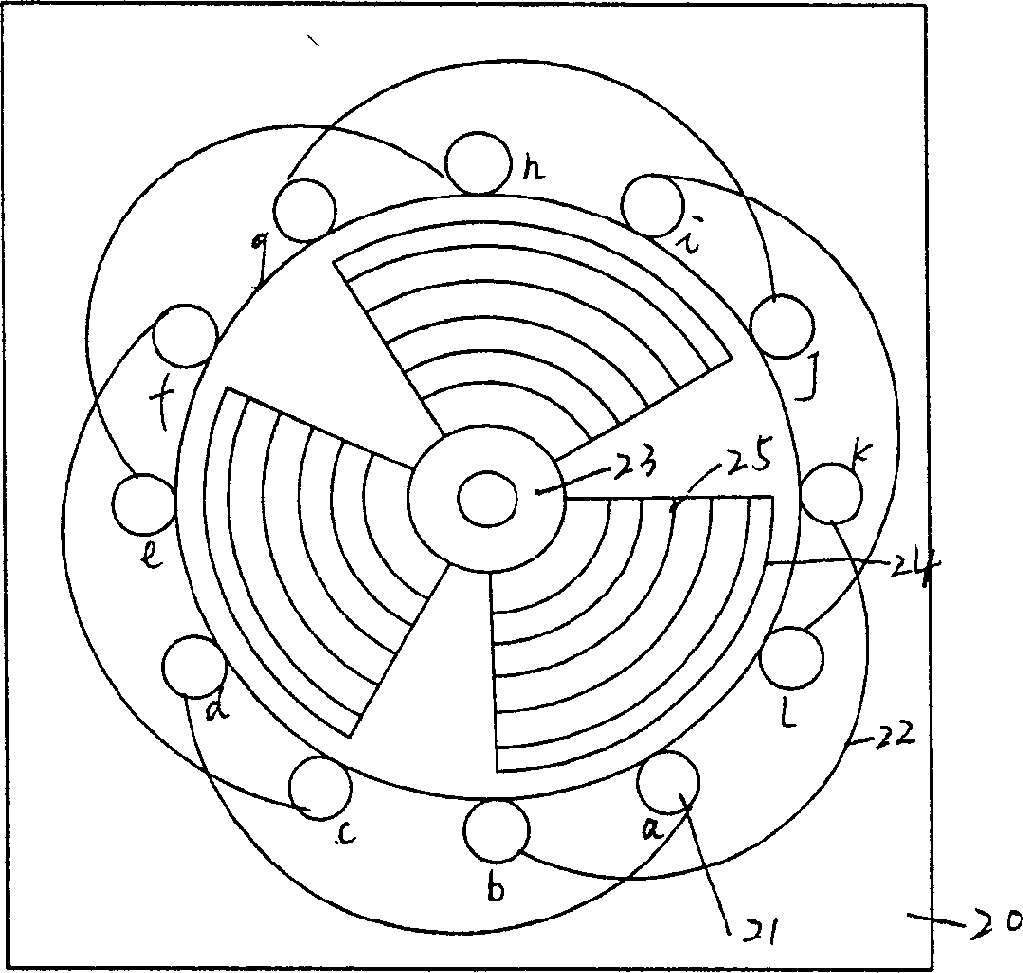

[0009] The invention is composed of three parts, namely an accelerator, a reluctance motor and a controller. The accelerator is composed of two rows of planetary rows and some driving gears and driven gears, such as figure 2 It is shown that the outer ring gear 9 of the first row of planets meshes with four planetary gears (gear 10, gear 10a, gear 10b and gear 10c), and the rotating shaft of each planetary gear is fixed on the planetary ring 10f, and the planetary ring It is fixedly connected with the hollow rotating shaft 10d through the metal connecting rod, and the hollow rotating shaft is provided with a fixer 10e (such as figure 1 As shown), the sun gear 11 is externally meshed with the planetary gear, and the drive shaft 11a fixedly connected with the sun gear is respectively provided with a driving gear 11b and a retainer 11c; the second planetary row, its external gear 12 and the first The transmission shaft 11a of the sun gear of the first row is fixedly connected, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com