Multilayer plated fuel line parts for automobile

A multi-layer plating, automotive technology, applied in superimposed layer plating, low-pressure fuel injection, fuel injection devices, etc., can solve problems such as damage to the trivalent chromate coating, unsuitable use, broken O-rings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

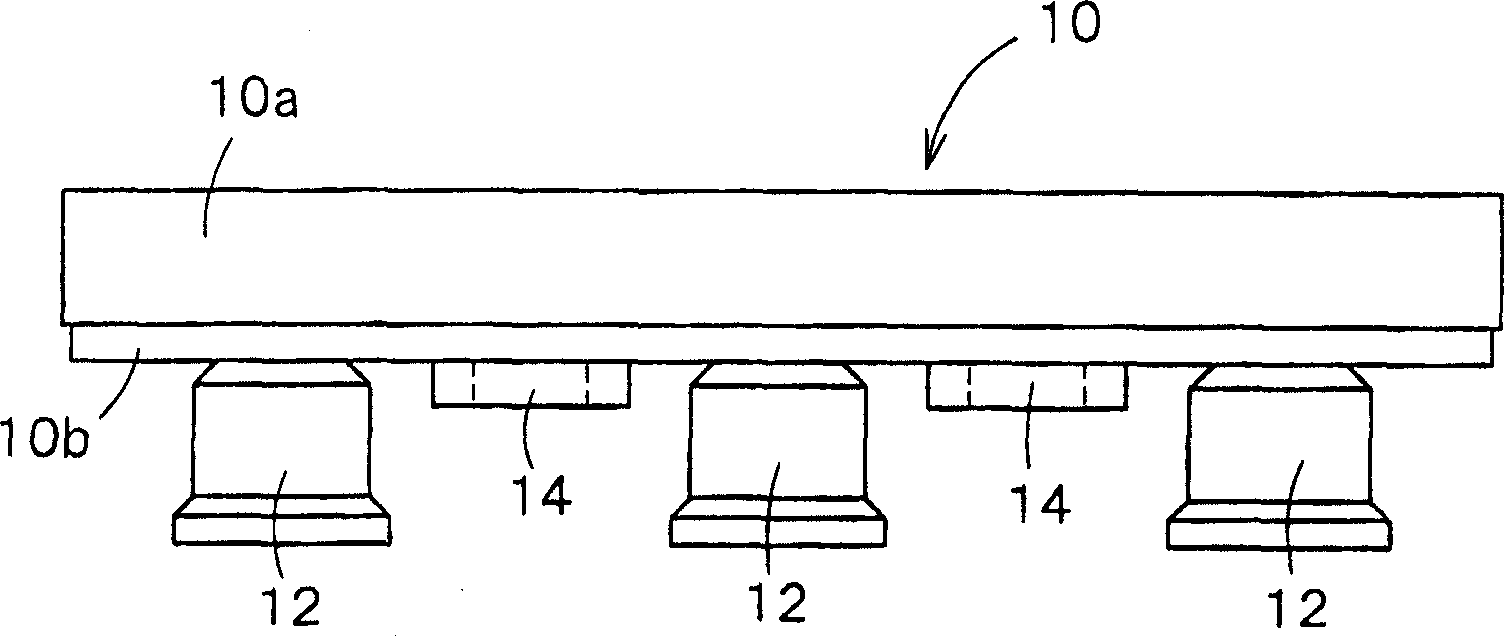

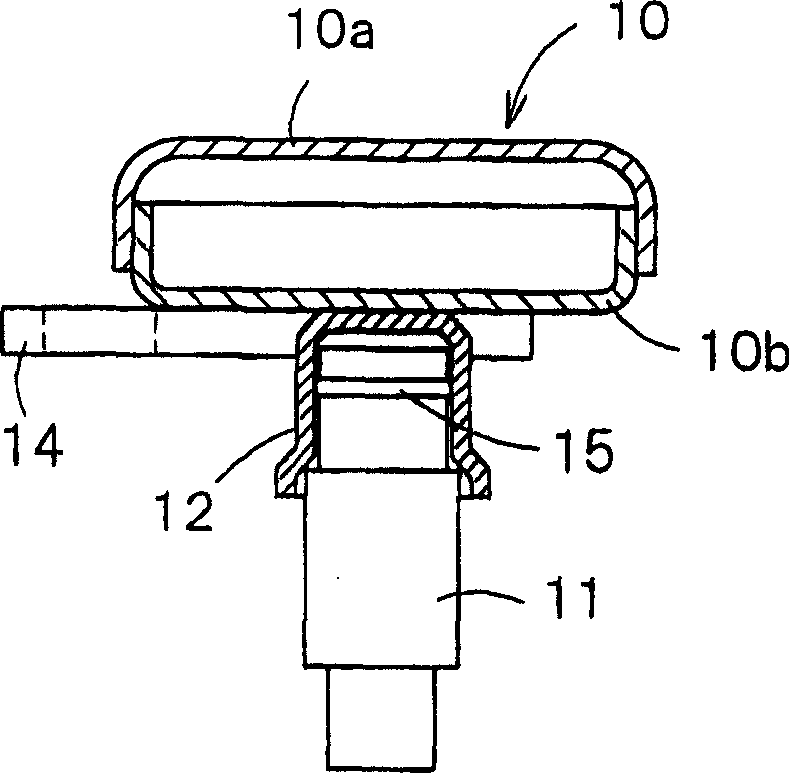

[0025] figure 1 Indicates an oil supply pipe to which the present invention is applied to perform multilayer plating treatment, figure 2 is a cross-sectional view.

[0026] The main body portion 10 of the oil supply pipe is composed of two casings, an upper casing 10a and a lower casing 10b, which are separately formed by press working a steel plate. After the upper casing 10a is assembled to the lower casing 10b, the Brazing is performed on the overlapped portion to join them together. An oil cup 12 for installing the oil injector 11 is installed on the lower surface of the lower housing 10b. 14 is a bracket for fixing.

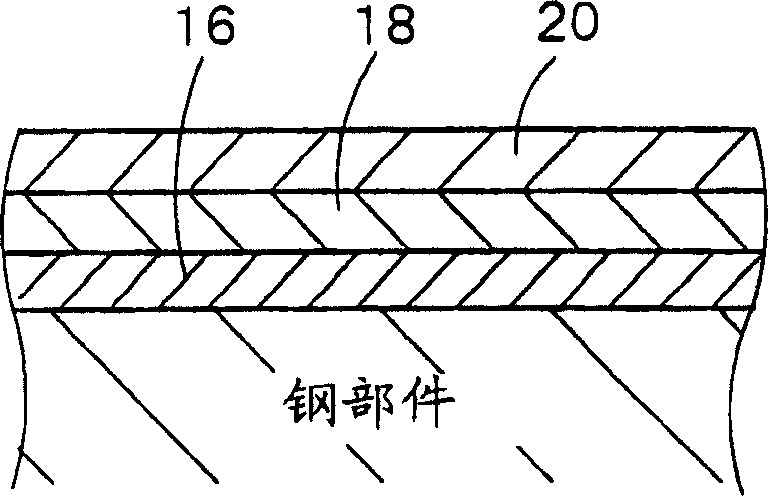

[0027] The surface of the oil supply pipe is covered by 3 layers of plating layers, and the 3 layers of plating layers include: the Zn-Ni alloy plating film 16 on the bottom layer of the covering surface, the Zn coating film 18 on the top layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com