Sealing structure of light emitting diodes

A technology of light-emitting diodes and packaging structures, applied in the direction of electrical components, circuits, semiconductor devices, etc., to achieve the effects of smaller materials, shorter conductive paths, and smaller base areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

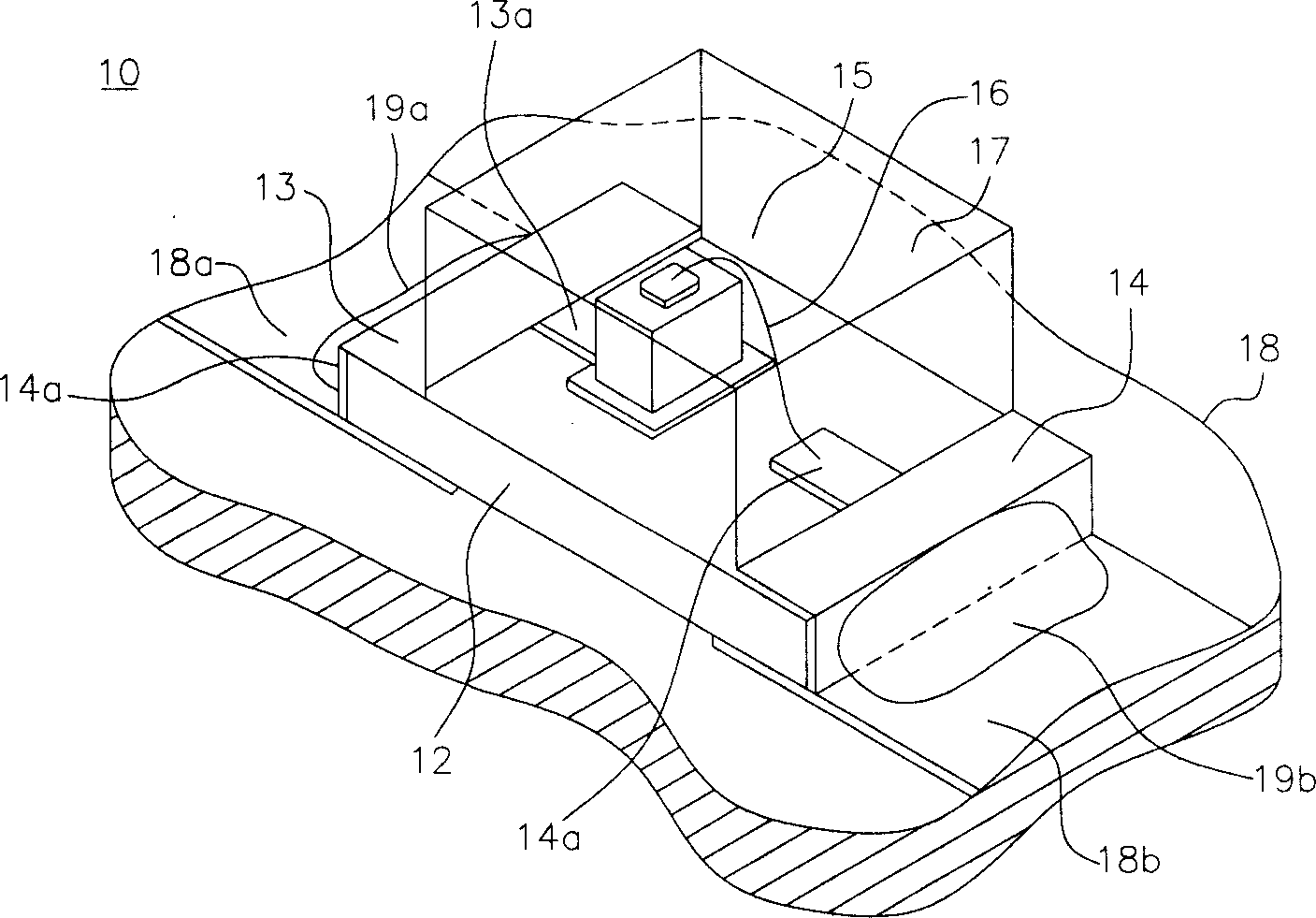

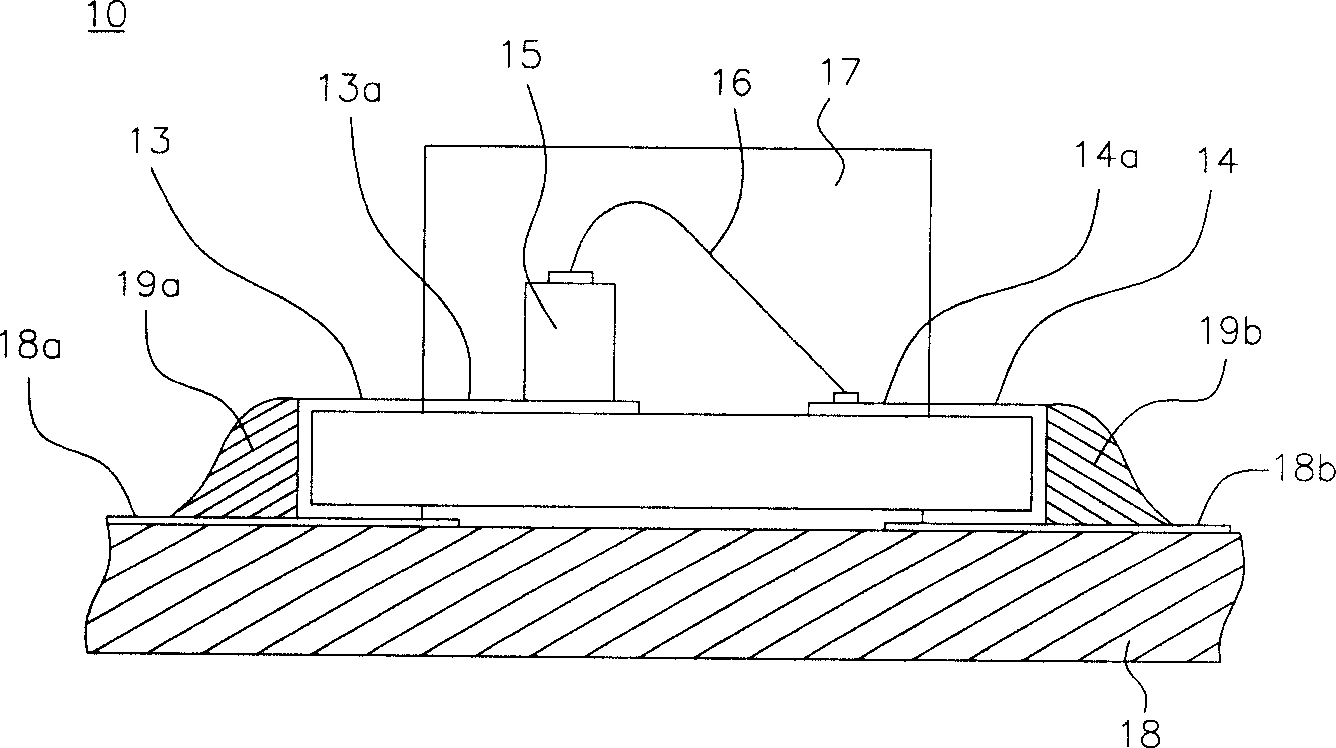

[0038] In order to further miniaturize the packaging structure of the light emitting diode, the present invention drills a through hole in the base, and forms a conductive column in the through hole to replace the conductive film in the existing packaging structure. Because the conductive thin film in the existing packaging structure needs to surround the top surface, side surface and bottom surface of the base, there are many restrictions on the size design of the structure miniaturization.

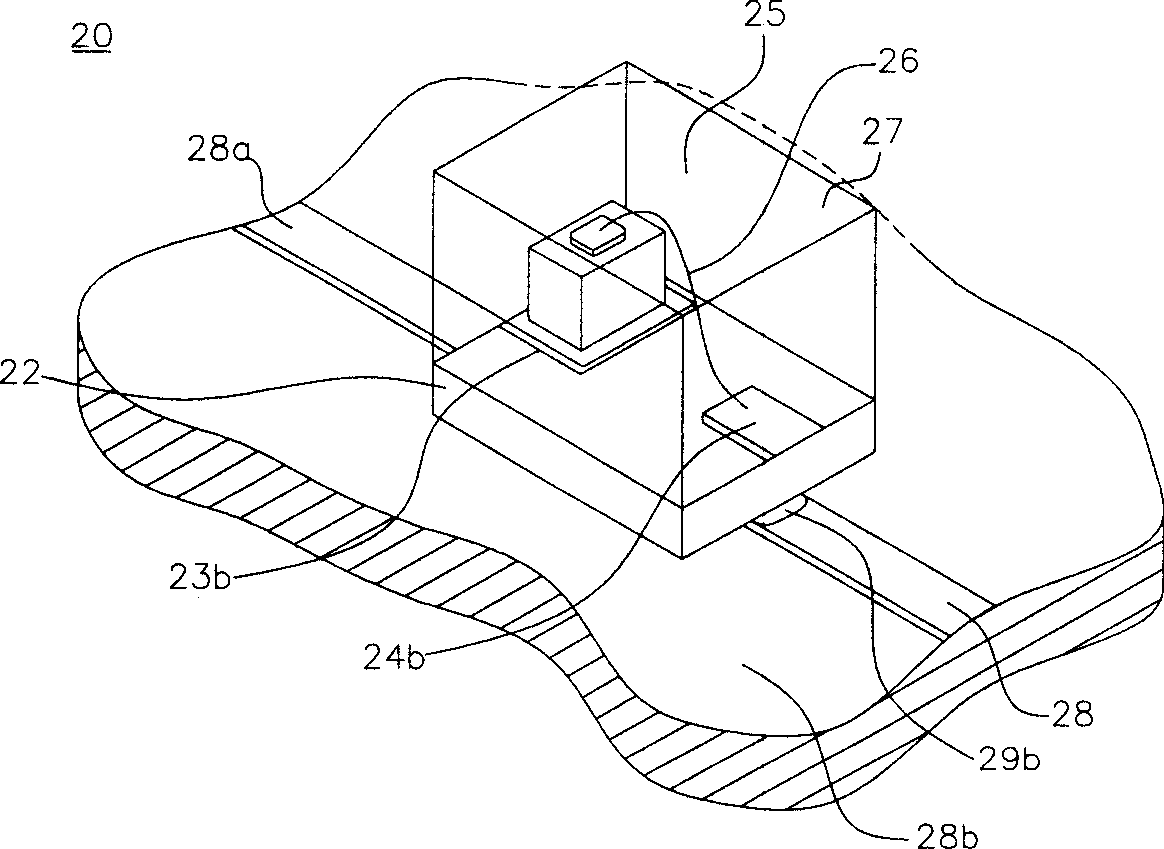

[0039] Please refer to Figure 2A and Figure 2B , which respectively show a schematic perspective view and a schematic cross-sectional view of a light emitting diode packaging structure according to a preferred embodiment of the present invention. In this embodiment, two through holes 23 , 24 are formed on the base 22 of the diode package structure 20 , and conductive posts are formed therein. In the practice of manufacturing the conductive pillars, the top ends 23 b and 24 b of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com