Coated printing sheet and process for making same

A printing paper and coating technology, applied in the field of printing paper, can solve the problems of reducing printing speed, moisturizing ink, low gloss value of printing surface, and bruising.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

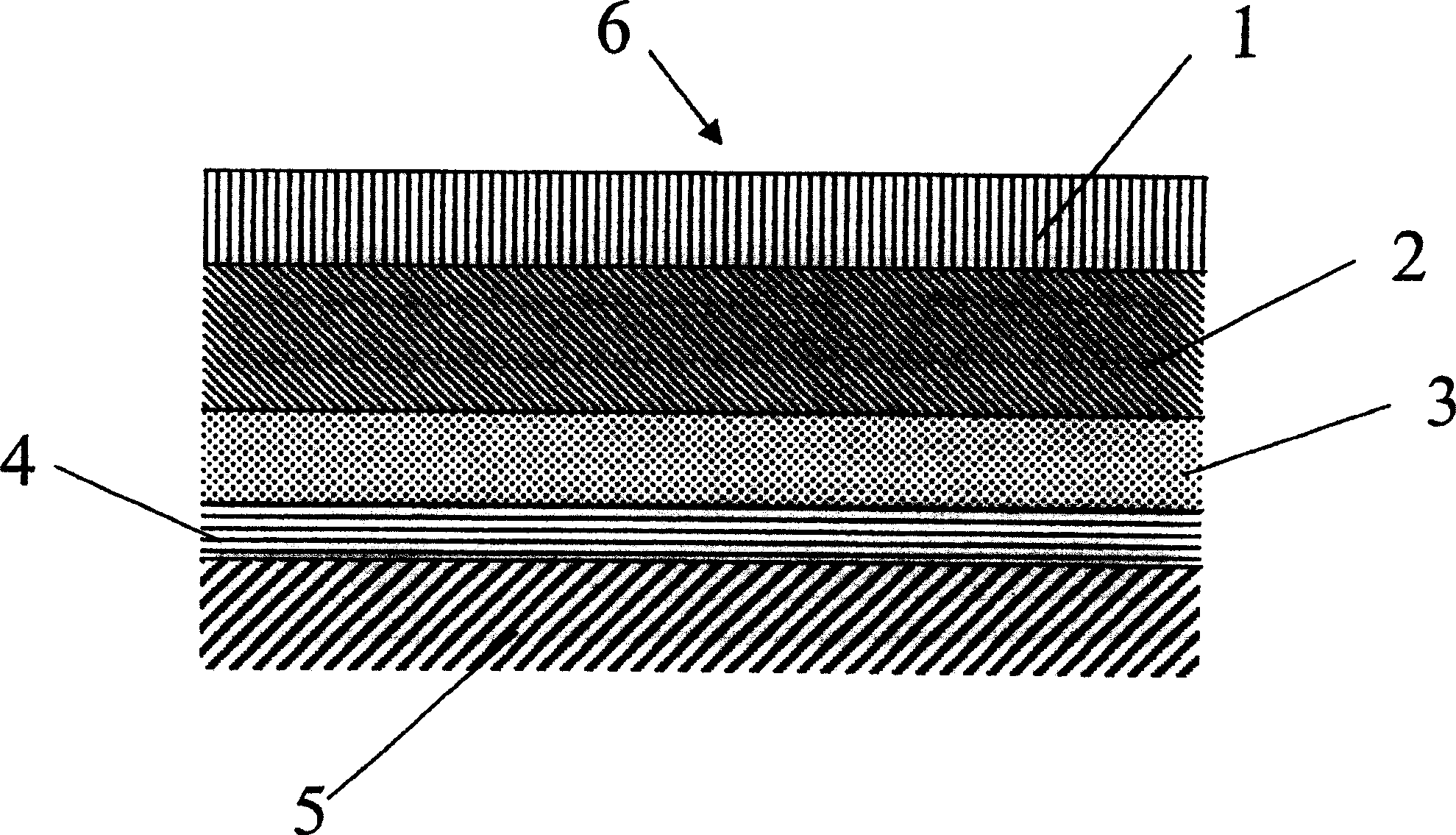

[0044] Referring to the accompanying drawings, the purpose of which is to illustrate preferred embodiments of the invention and not to limit it, figure 1 A cut sheet is shown, which represents a first embodiment of the printed sheet of the invention. The printing paper comprises a substrate 5, in which figure 1 Only the surface layer is shown. The first layer on the substrate 5 is a possibly colored size layer 4 , which is then followed by a third layer 3 , a second layer 2 and a skin layer 1 . figure 1 Only one side of the printed paper is shown, which is usually the case if both sides of the printed paper are coated, figure 1 The structure shown in is also present on the bottom of the printed paper with layers in the order figure 1 A mirror image of the order shown.

[0045] In the following, each layer and its components will be described in detail, and finally the paper manufacturing method and performance analysis of the finished printing paper will be explained. In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific volume | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com