Natural stone texture imitating ceramic tile and manufacturing method thereof

A technology of imitating natural stone and manufacturing method, which is applied in the field of ceramic tiles imitating natural stone lines and its manufacturing field, can solve the problems of large and complicated equipment, no natural stone, and rigid lines, etc., and achieves strong integrity, decoration and use. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

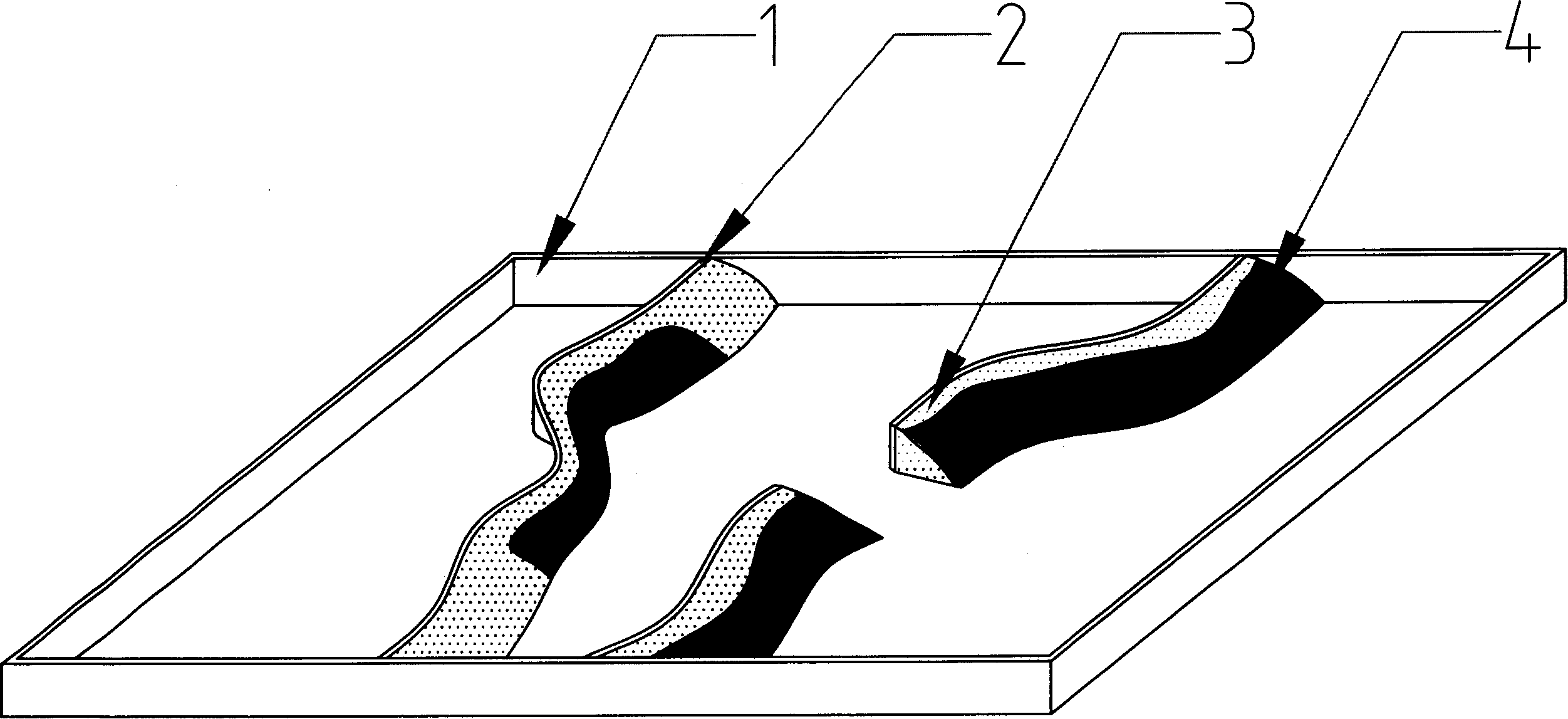

[0022] Such as figure 1 As shown, a grid bar 2 is arranged in the grid frame 1, and the shape of the grid bar 2 is the imitated natural stone line shape, and the basic powder pile 3 is accumulated by the grid bar 2, and the shape of the basic powder pile 3 Consistent with the shape of the grid bar 2, the line powder 4 is covered on the slope 3 of the basic powder pile. You can control the shape of the lines. And the position where the line powder 4 covers the slope of the foundation powder pile 3 can be set by the wiring line powder device 11, thereby controlling the position where the lines appear on the tiles.

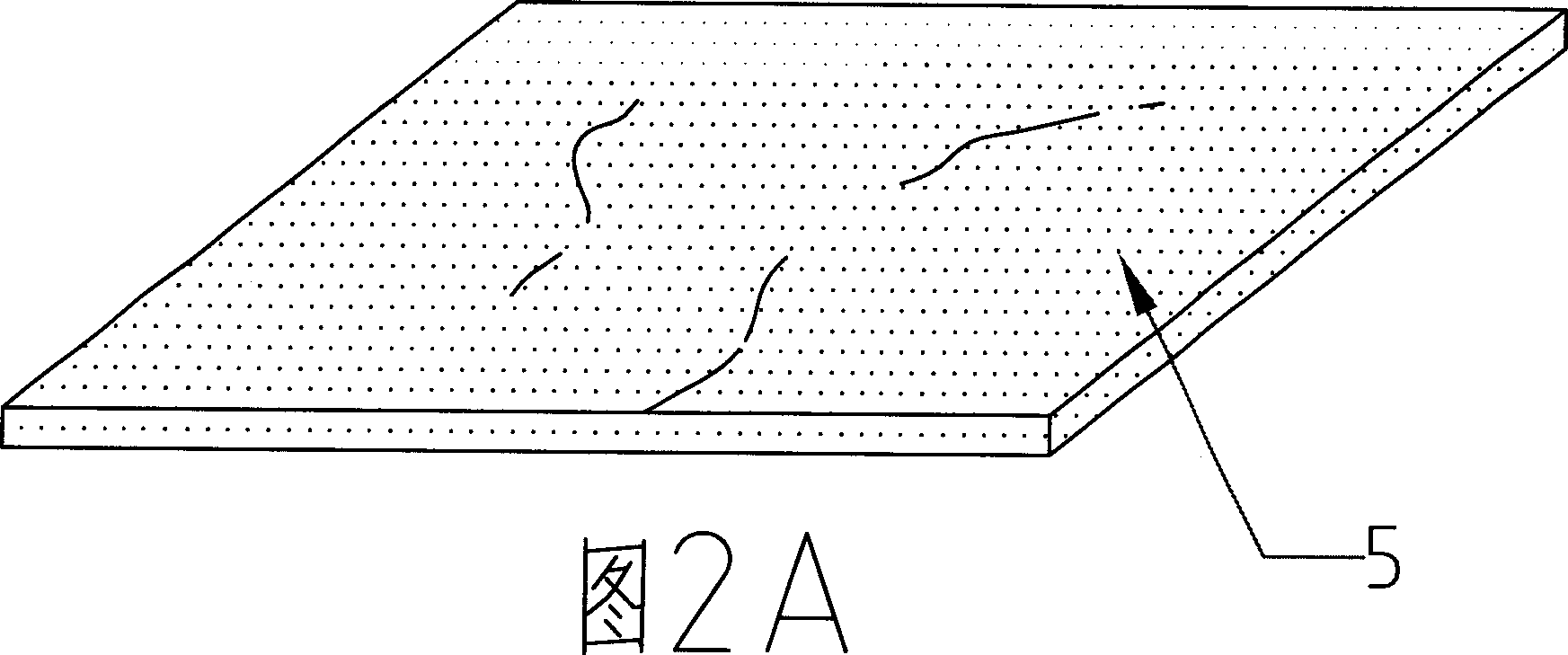

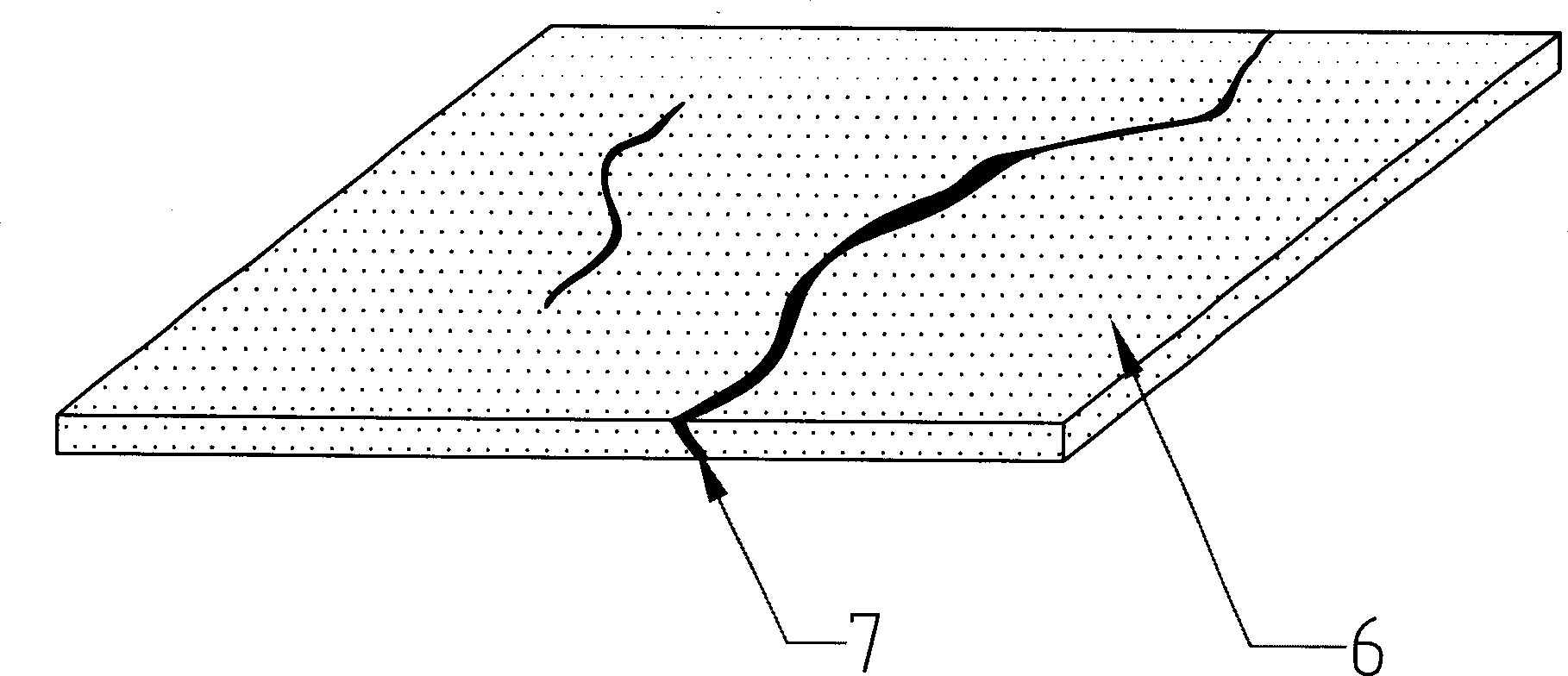

[0023] Since the imitation natural stone lines manufactured by the method can penetrate through the brick body, the section decoration effect of the ceramic tile is the same as that of the natural stone. as attached Figure 2B As shown, after the section line 7 of the finished ceramic tile is processed into an arc angle (or other special-shaped angle), the imitati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap