A structure for making up wheel hub by multiple motors

A technology of electric mechanism and wheel hub motor, which is applied in synchronous motor with stationary armature and rotating magnet, rider drive, transportation and packaging, etc., which can solve the problems of high cost, high cost of wheel hub motor, and many restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

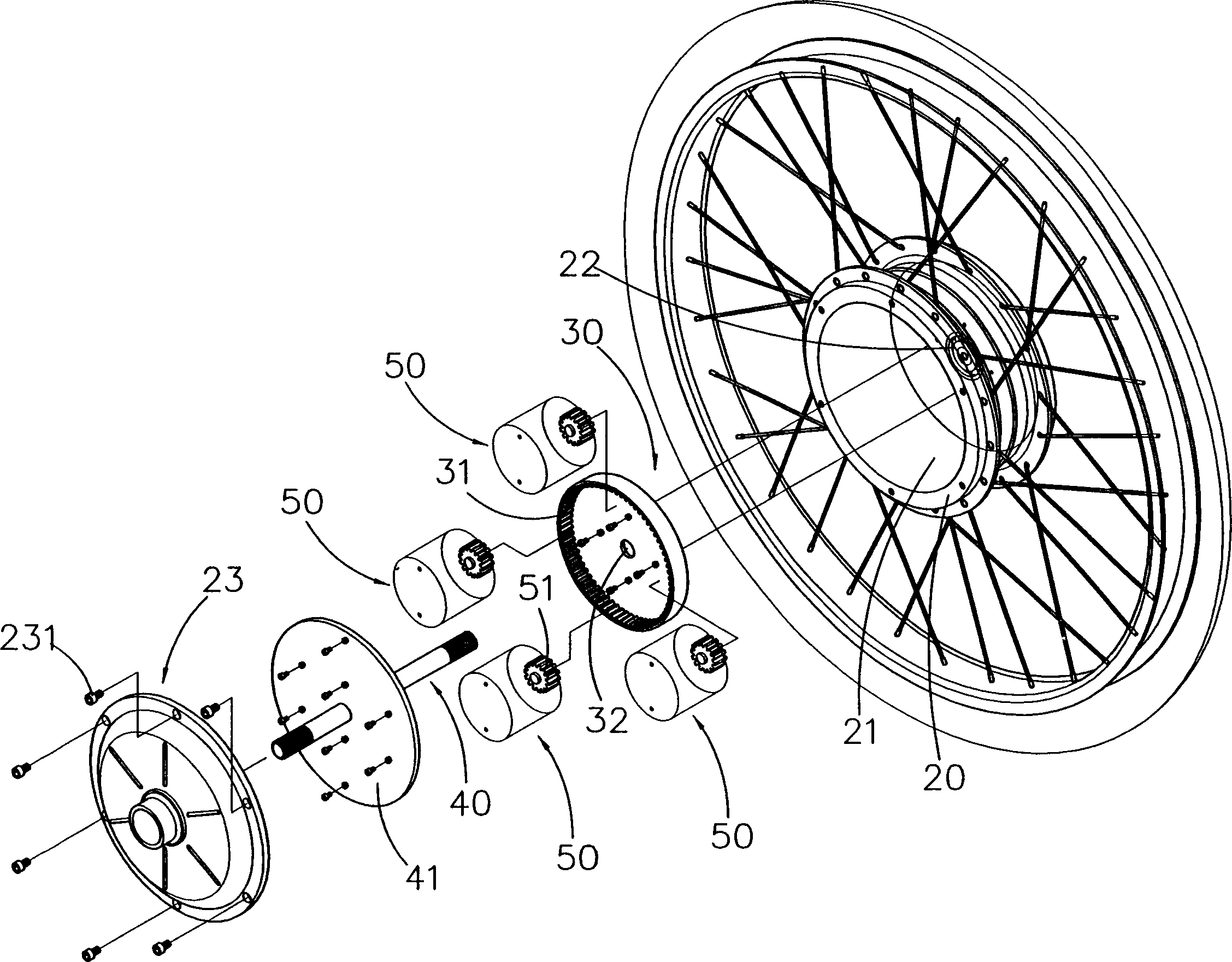

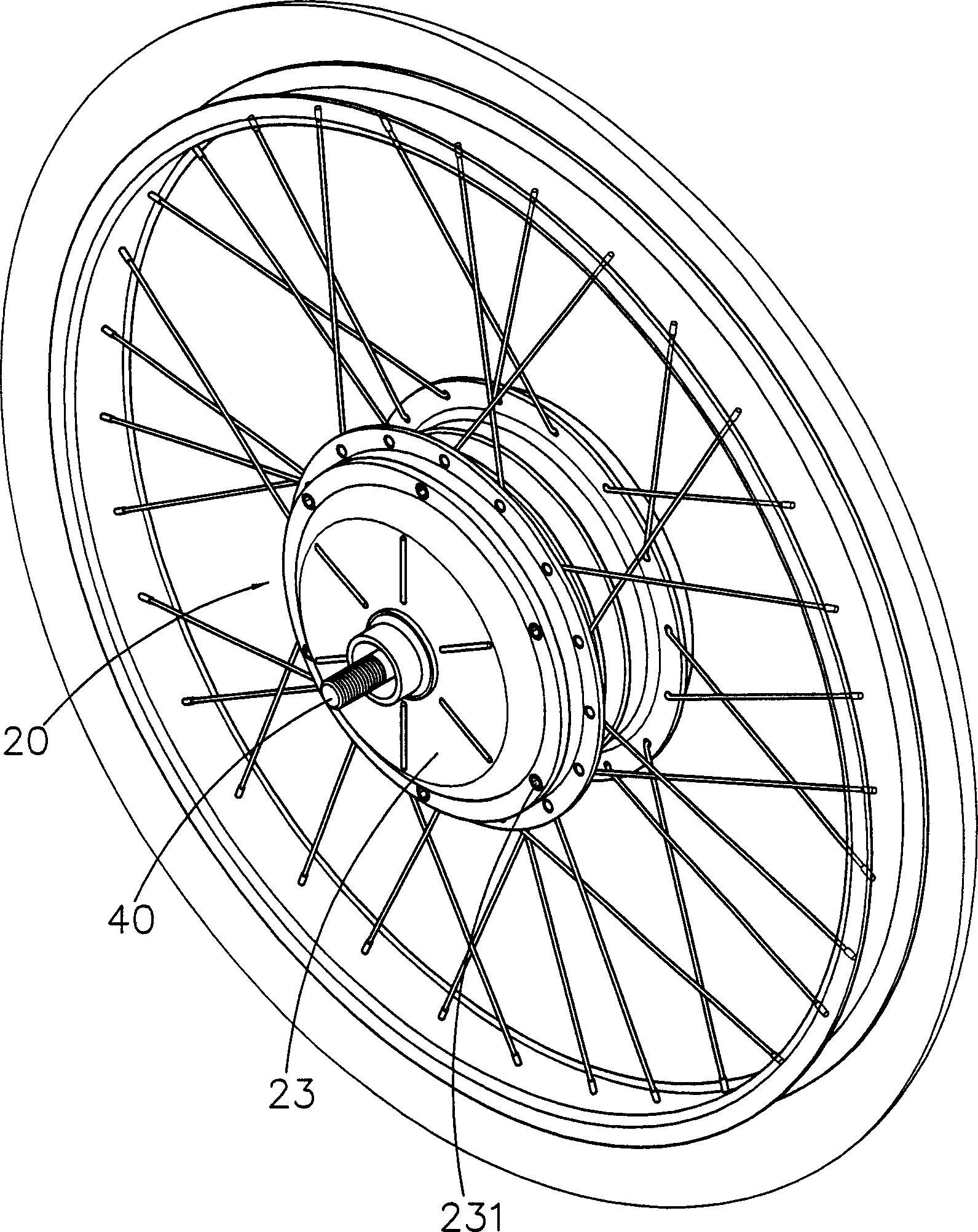

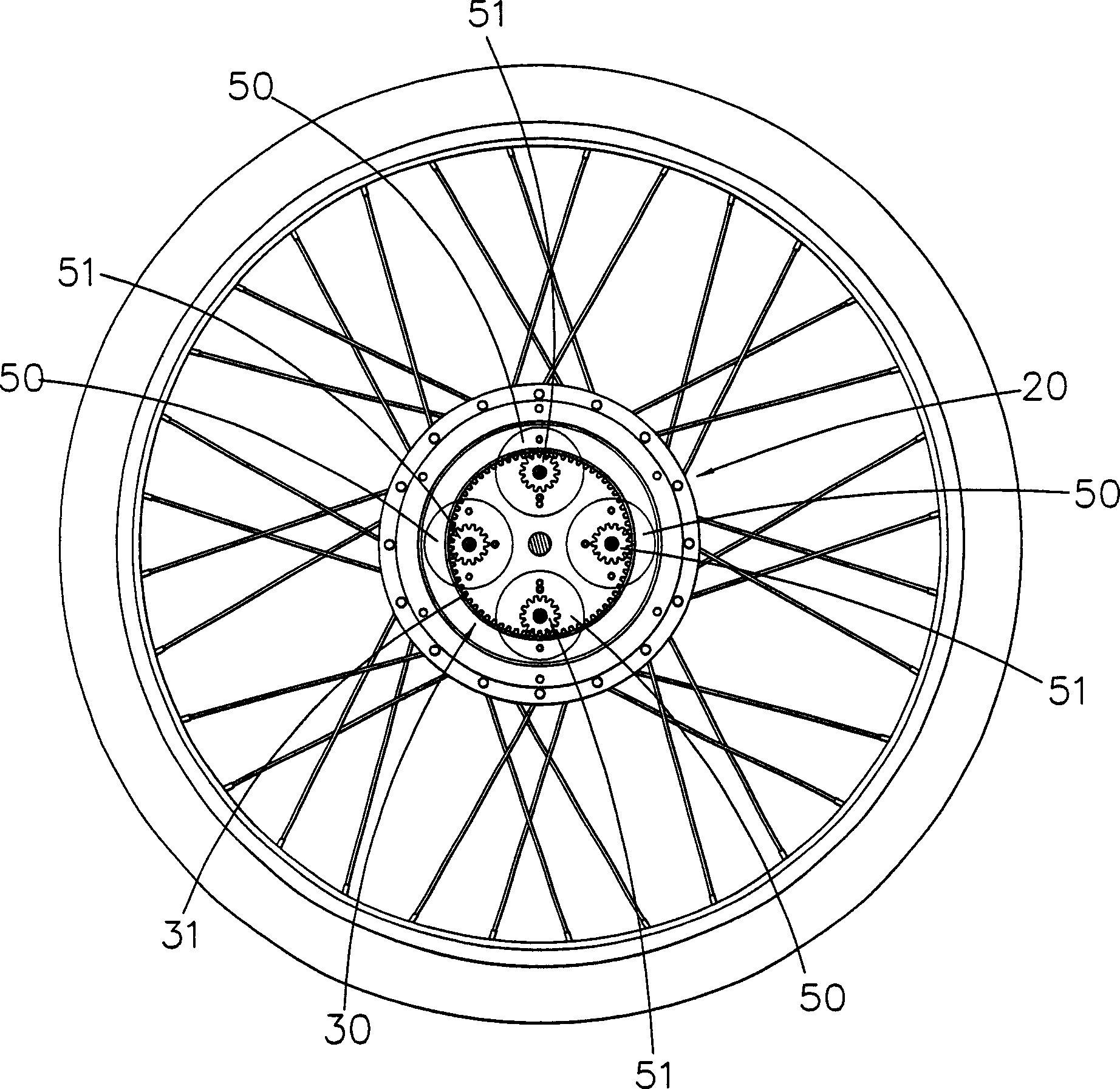

[0024] For the present invention to achieve the above-mentioned purpose, the technology, means and other effects adopted, hereby give a preferred feasible embodiment and describe it in detail in conjunction with the drawings; at first, please refer to Figure 1-5 As shown, the embodiment of the present invention provides a structure in which a plurality of electric motors are used to form an in-wheel motor. The main purpose is to integrate a plurality of independent motors into the hub through a drive chainring and a spindle, so that it can be operated according to the actual road conditions. Adequate power output, where:

[0025] The wheel hub 20 is the wheel hub 20 of the electric bicycle 60 (it can be a front wheel or a rear wheel). There is an accommodating space 21 formed in the wheel hub 20, and a perforation is provided on the side wall of the accommodating space 21 of the wheel hub 20, and can be assembled. A bearing 22 is inside; the accommodating space 21 of the whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com