Environment-friendly dust removal device

A kind of dust removal equipment and environmental protection technology, applied in the field of environmental protection dust removal equipment, can solve the problems of single dust removal function and poor dust removal effect, achieve good dust removal effect, easy to clean, easy to clean and replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

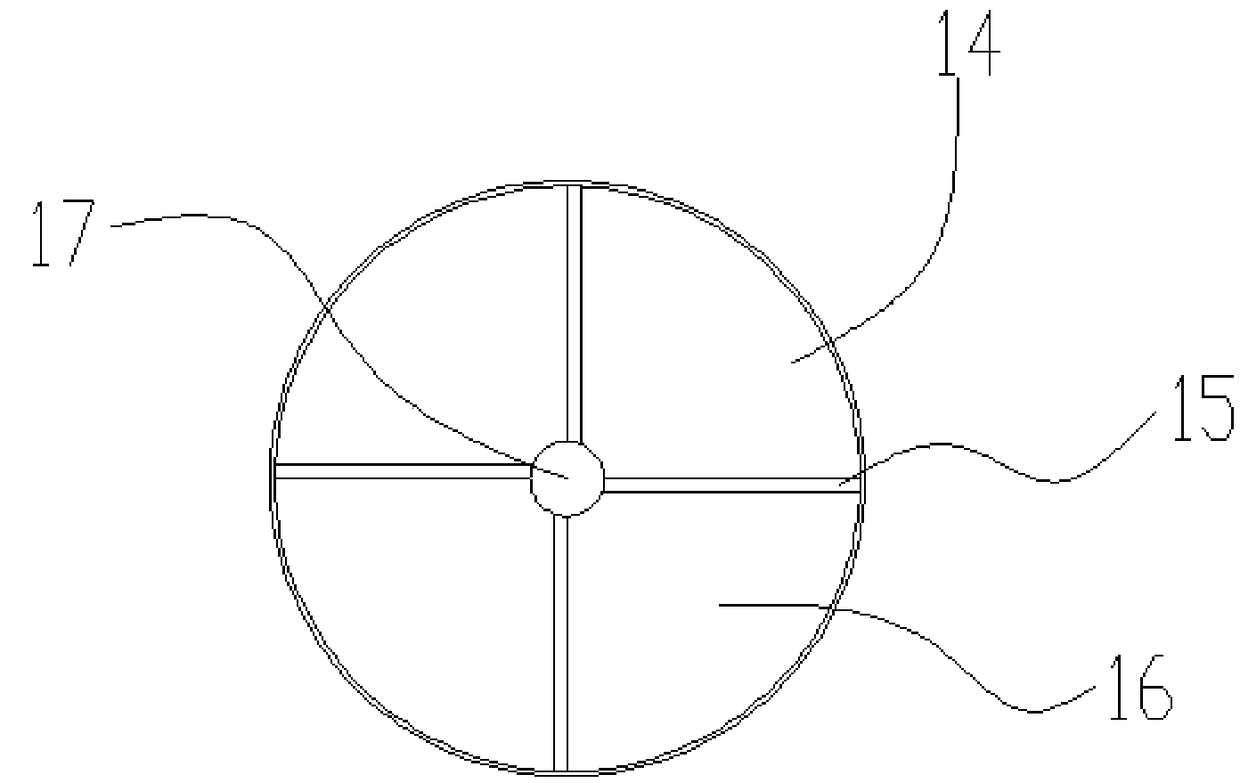

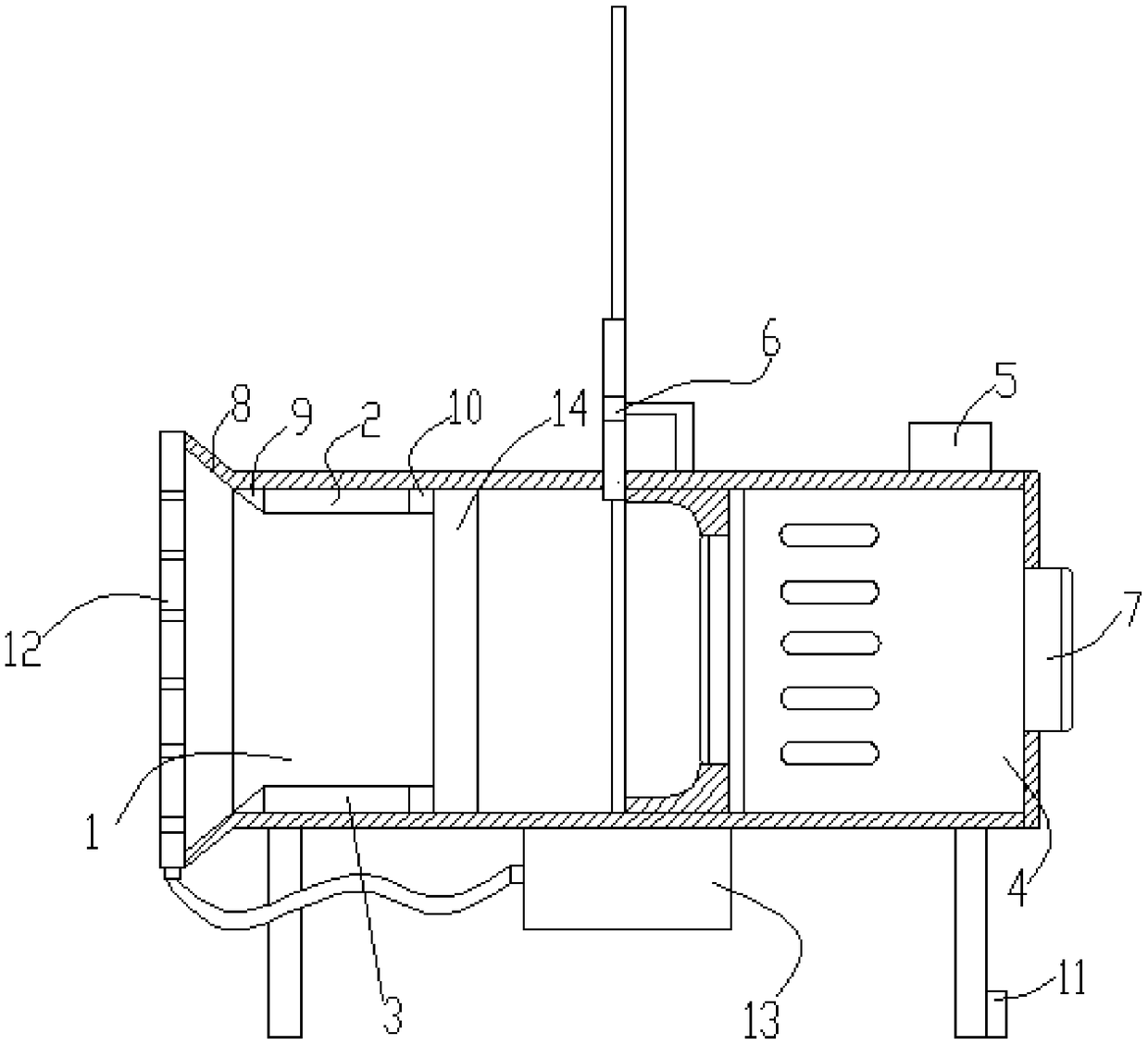

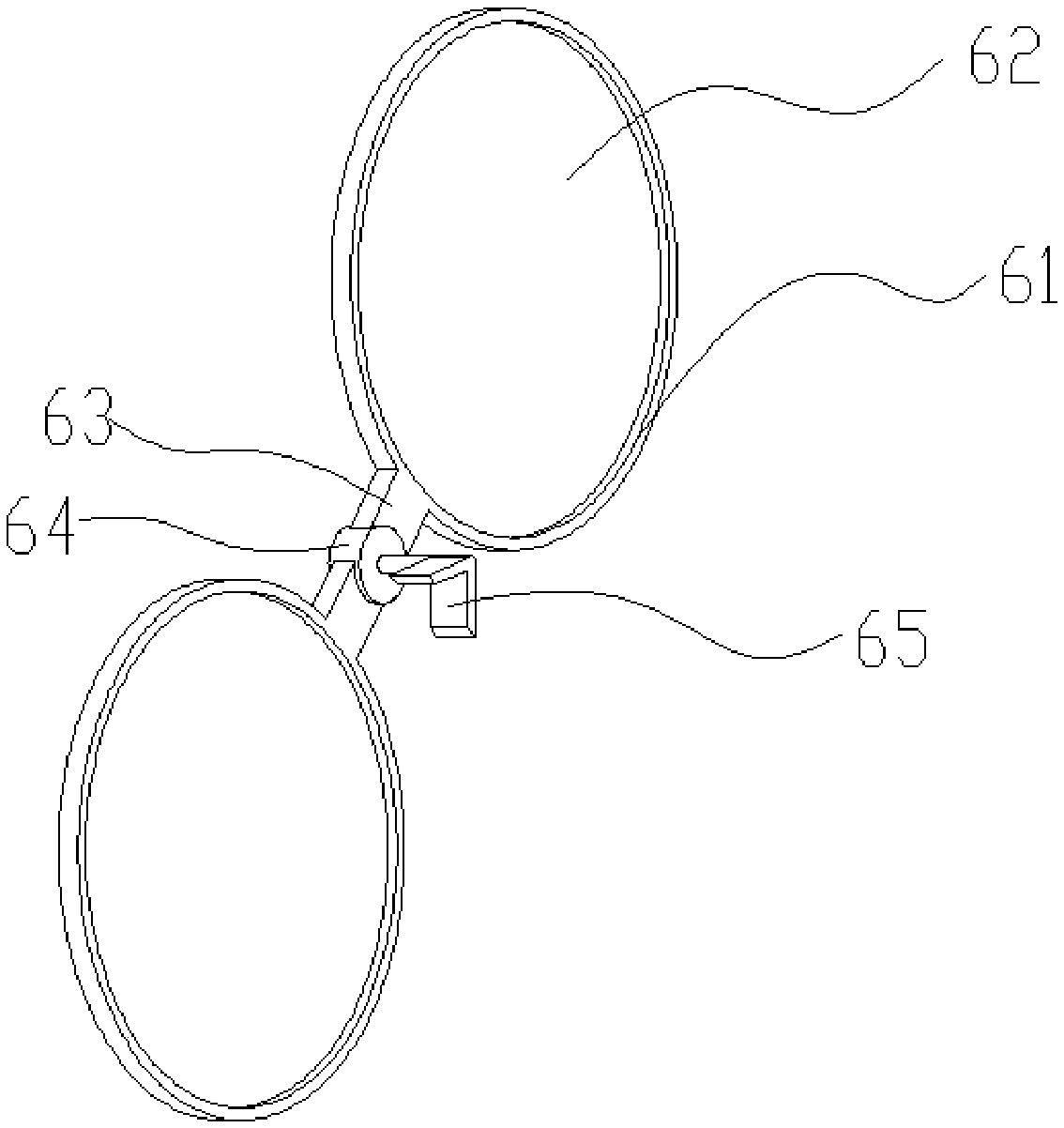

[0028] Such as Figure 1-3 As shown, it includes: dust removal part 1, first electrode plate 2, second electrode plate 3, fan 4, control device 5, filter device 6, exhaust port 7, pipe body 8, proximal insulation pad 9, remote insulation Pad 10, ground shrapnel 11, cooling device 12, water circulation device 13, blocking device 14, fixed rod 15, loose-leaf fan 16, fixed block 17, fixed ring 61, filter screen 62, rotating arm 63, rotating shaft 64 and fixed frame 65;

[0029] Such as figure 1 As shown, one end of the tube body 8 is provided with a dust removal part 1, and the dust removal part 1 is composed of a first electrode plate 2 and a second electrode plate 3; the first electrode plate 2 and the second electrode plate 3 are arranged on the inner wall of the tube body 8 The upper and lower sides are used to absorb the dust and particles in the gas passing through the dust removal part 1; the other end of the pipe body 8 is provided with a fan 4, and the tail end of the ...

Embodiment 2

[0037] Such as figure 2 As shown, compared with Embodiment 1, Embodiment 2 is provided with a blocking device 14 between the dust removal part 1 and the filter device 6 on the basis of Embodiment 1. The blocking device 14 includes: a fixed rod 15, a loose-leaf fan 16 and fixed block 17; fixed rod 15 and loose-leaf leaf 16 are set to four respectively, and one end of fixed rod 15 is fixed with the inwall of pipe body 8, and the other end is fixed with fast 17, and loose-leaf fan 16 is movably connected with fixed rod 15, and A torsion spring is provided at the joint, so that the loose-leaf fans 16 can swing in one direction. When there is no gas flow, the four loose-leaf fans 16 are closed. When the gas flows along the dust removal part 1 to the exhaust port 7, the loose-leaf fans 16 are opened; After the power is cut off, the loose-leaf fan 16 is automatically closed, and the dust adsorbed on the first electrode plate 2 and the second electrode plate 3 will not fall to the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com