Device for connecting rolling bearing to external engine body

A technology for connecting devices and external bodies, applied to the rigid brackets of bearing components, connecting components, wheel bearings, etc., which can solve problems such as inability to adapt and guarantee a constant value of transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

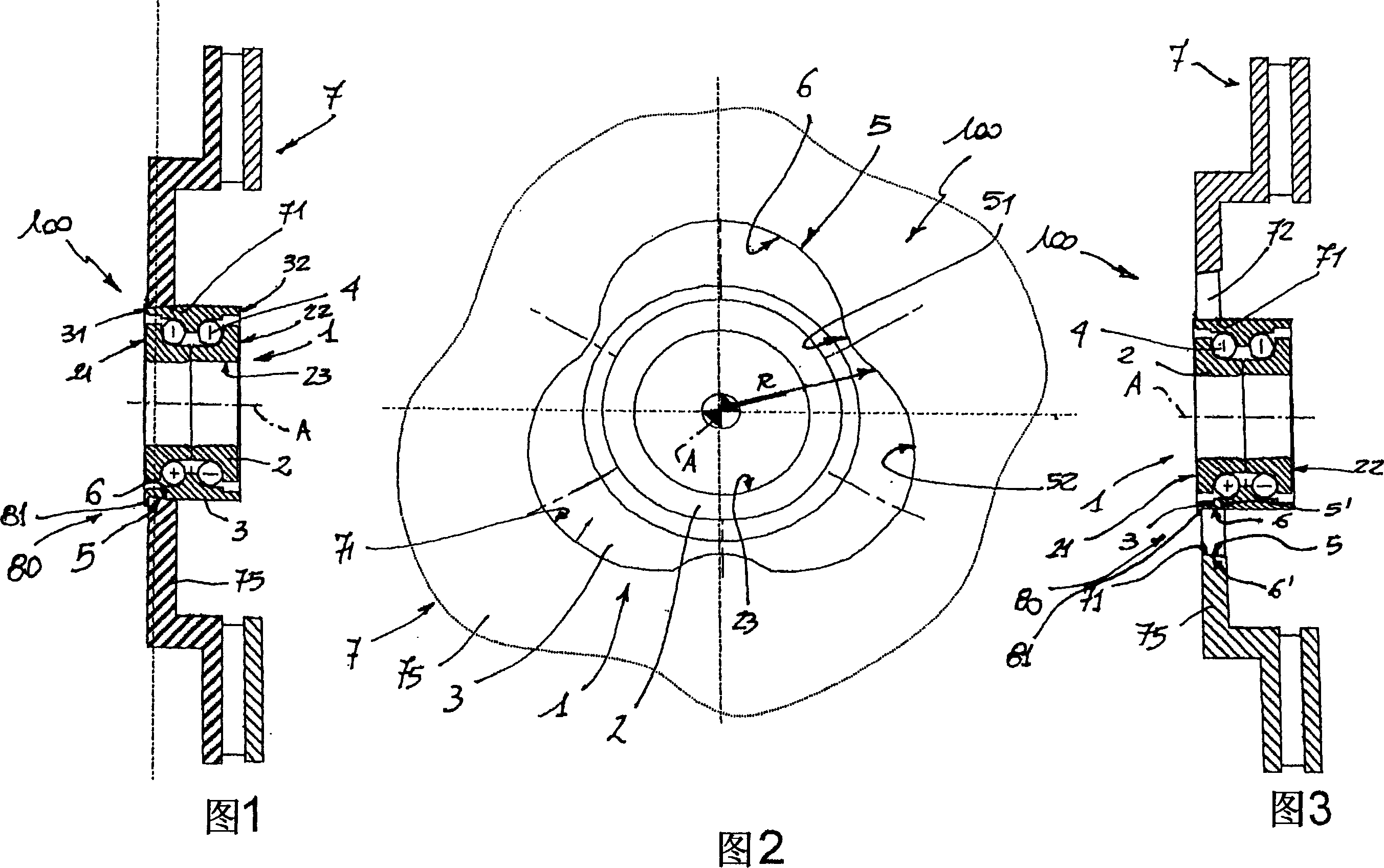

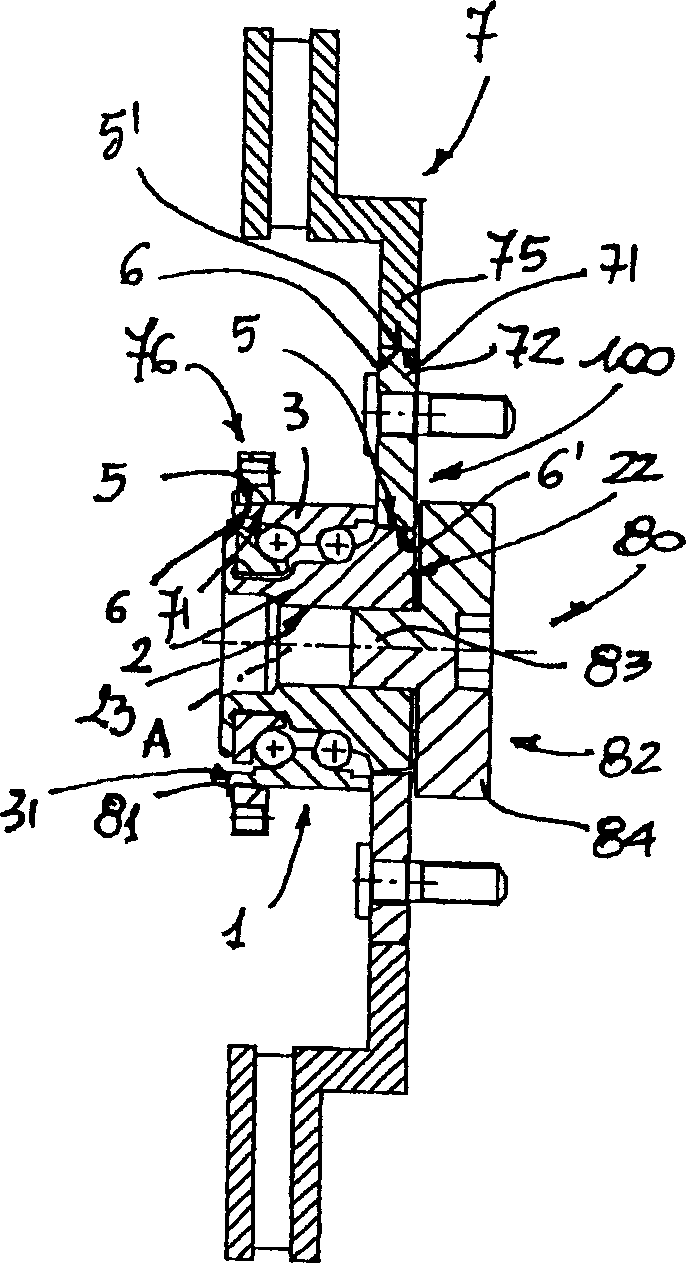

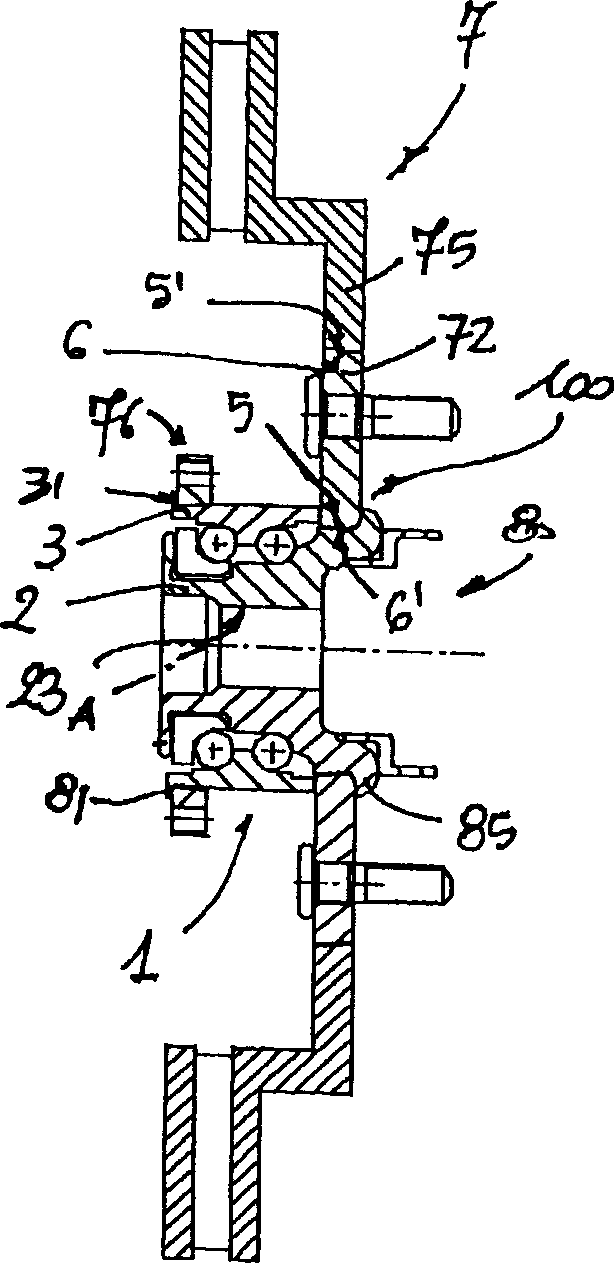

[0016] Referring to FIG. 1, reference numeral 100 denotes a connecting device for connecting a rolling bearing 1 to an outer body 7 as a whole.

[0017] The bearing 1 has a rotation axis A, and includes an inner race 2 coaxial with the axis A, an outer race 3 coaxial with the inner race 2, and a plurality of inner races 2 and outer races 3 Between the rolling body 4.

[0018] The inner race 2 is bounded in the axial direction by two annular surfaces 21 and 22 perpendicular to the axis A and in the radial direction by an inner cylinder 23 coaxial with the axis A. The outer race 3 is bounded in the axial direction by two annular surfaces 31 and 32 perpendicular to the axis A and in the radial direction by an outer cylindrical surface 33 coaxial with the axis A.

[0019] The outer body 7 defines a brake disc comprising an inner sleeve 71 engaged with the bearing 1 and an annular body 75 arranged perpendicular to the axis A and through which the inner sleeve 71 passes centrally. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com