Automatic correction laser measurement device and correction method

A technology of laser measurement and automatic correction, which is applied in optical recording/reproduction, head configuration/installation, instruments, etc., and can solve problems such as increased production costs, attenuation of light detection components, and measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

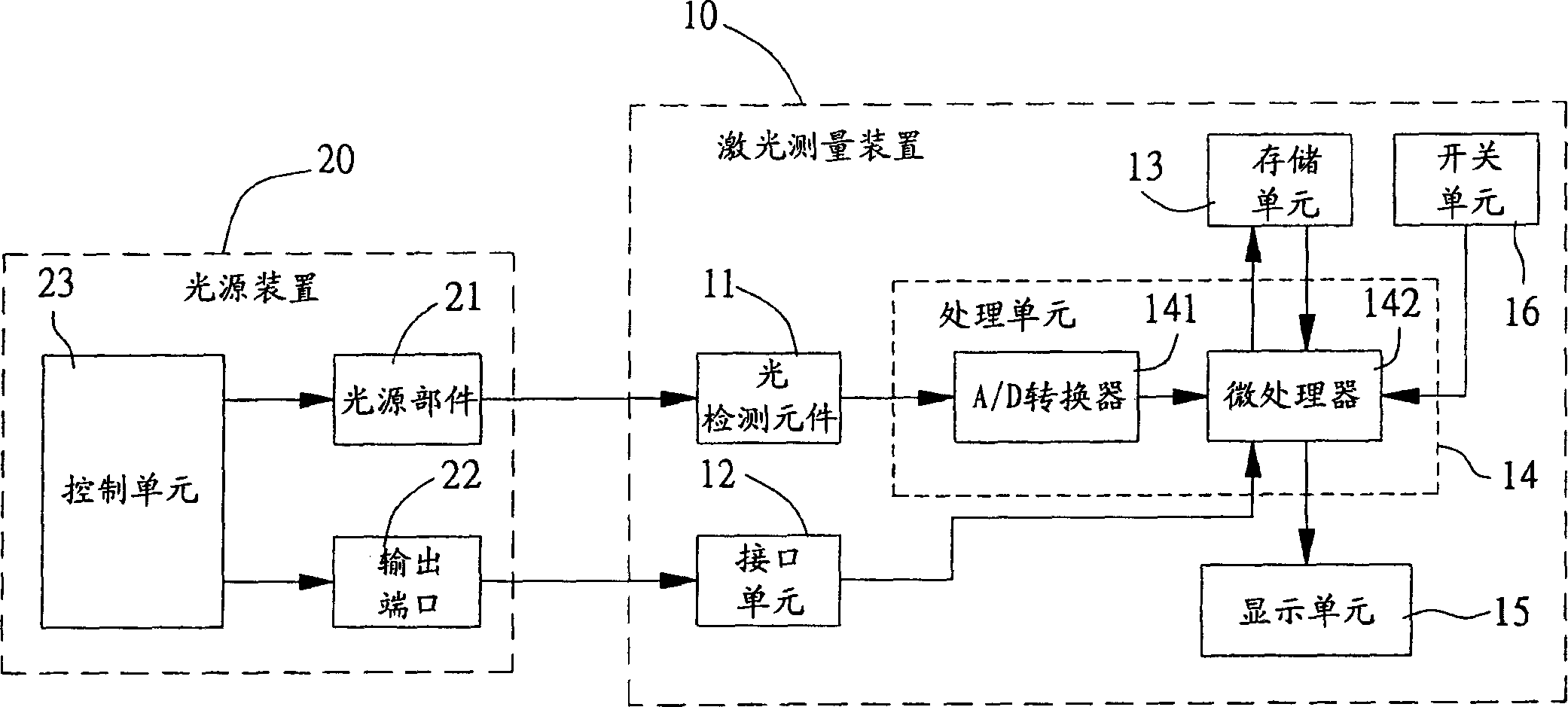

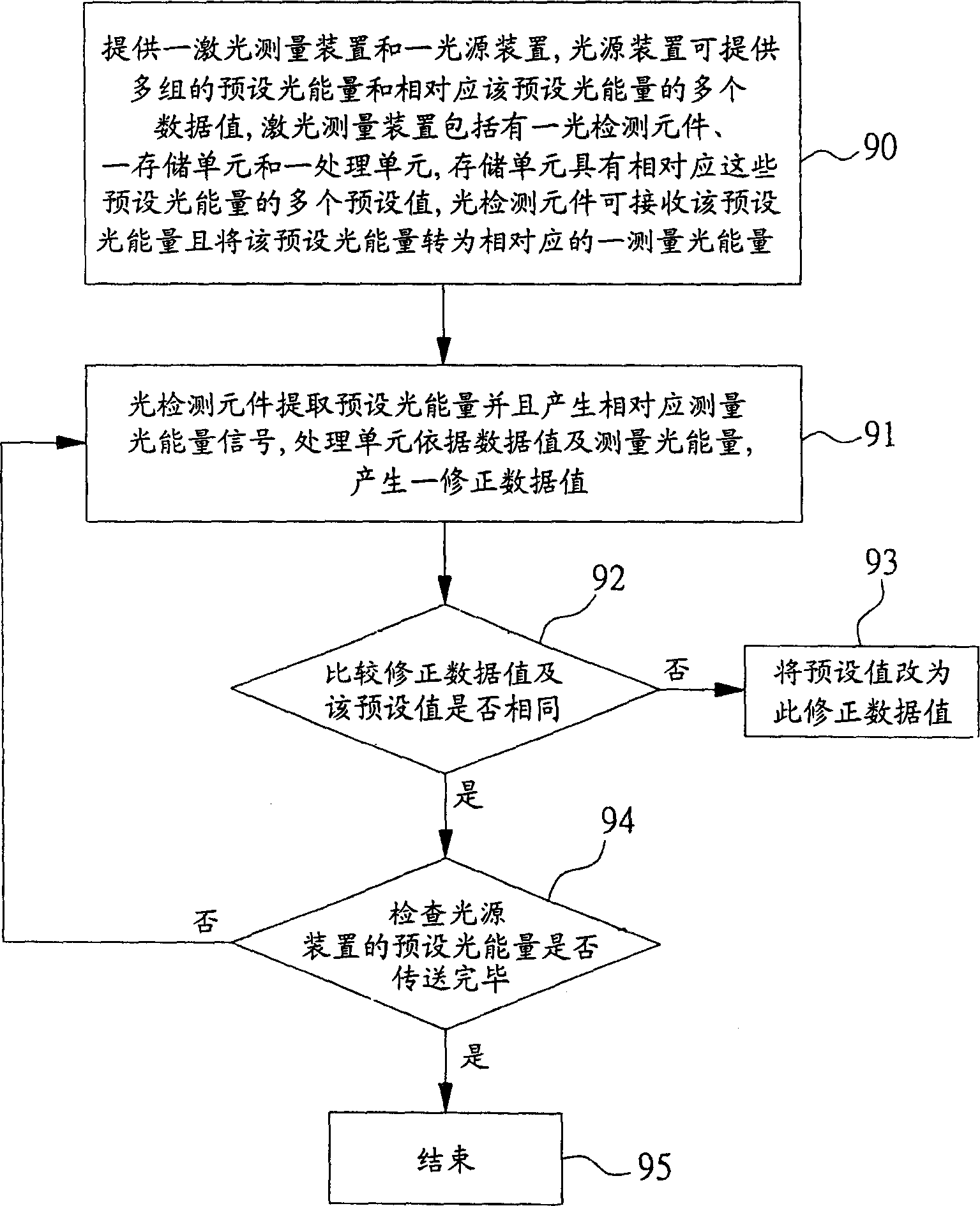

[0023] see figure 1 As shown, it is a preferred embodiment of an automatic calibration laser measuring device of the present invention. The laser measurement device 10 includes: a light detection element 11 , an interface unit 12 , a storage unit 13 , a processing unit 14 and a display unit. The storage unit 13 stores a correspondence table, the correspondence table provides the processing unit 14 to calculate the value of the light energy received by the light detection element 11, and the correspondence table has several preset values, each preset value corresponds to Based on a measured light energy signal and a preset light energy. The optical sensor 11 can receive the preset light energy projected from the outside and convert the preset light energy into a measured light energy and send it to the processing unit 14. After the processing unit 14 receives the measured light energy signal, the processing unit 14 Immediately calculate the value of the preset light energy wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com