Ring-shape coil auxiliary winding frame

A toroidal coil and bobbin technology, which is applied in the manufacture of coils, electrical components, inductors/transformers/magnets, etc., can solve the problems of wire cutting and paint removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, preferred embodiment of the present invention will be further described

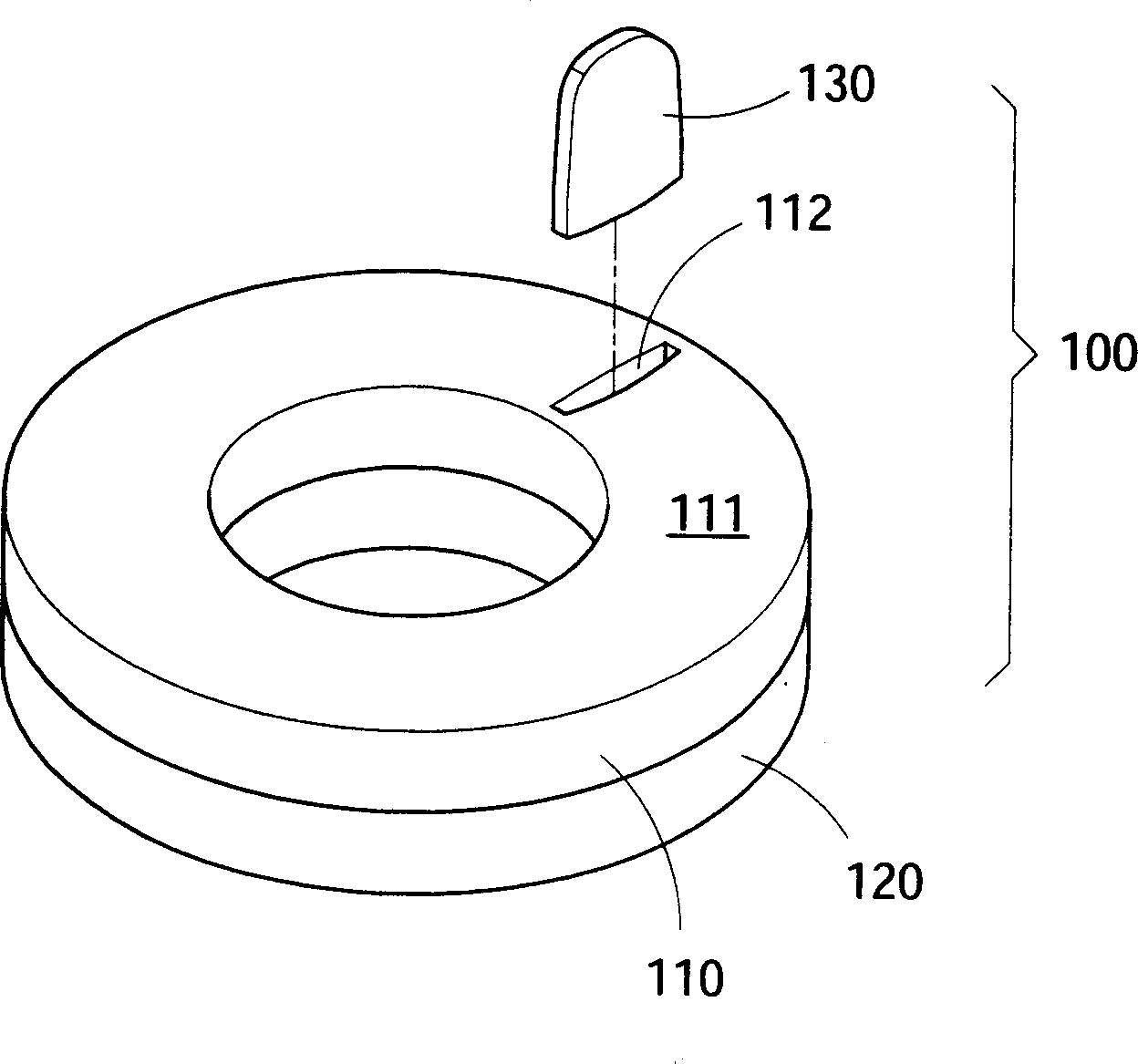

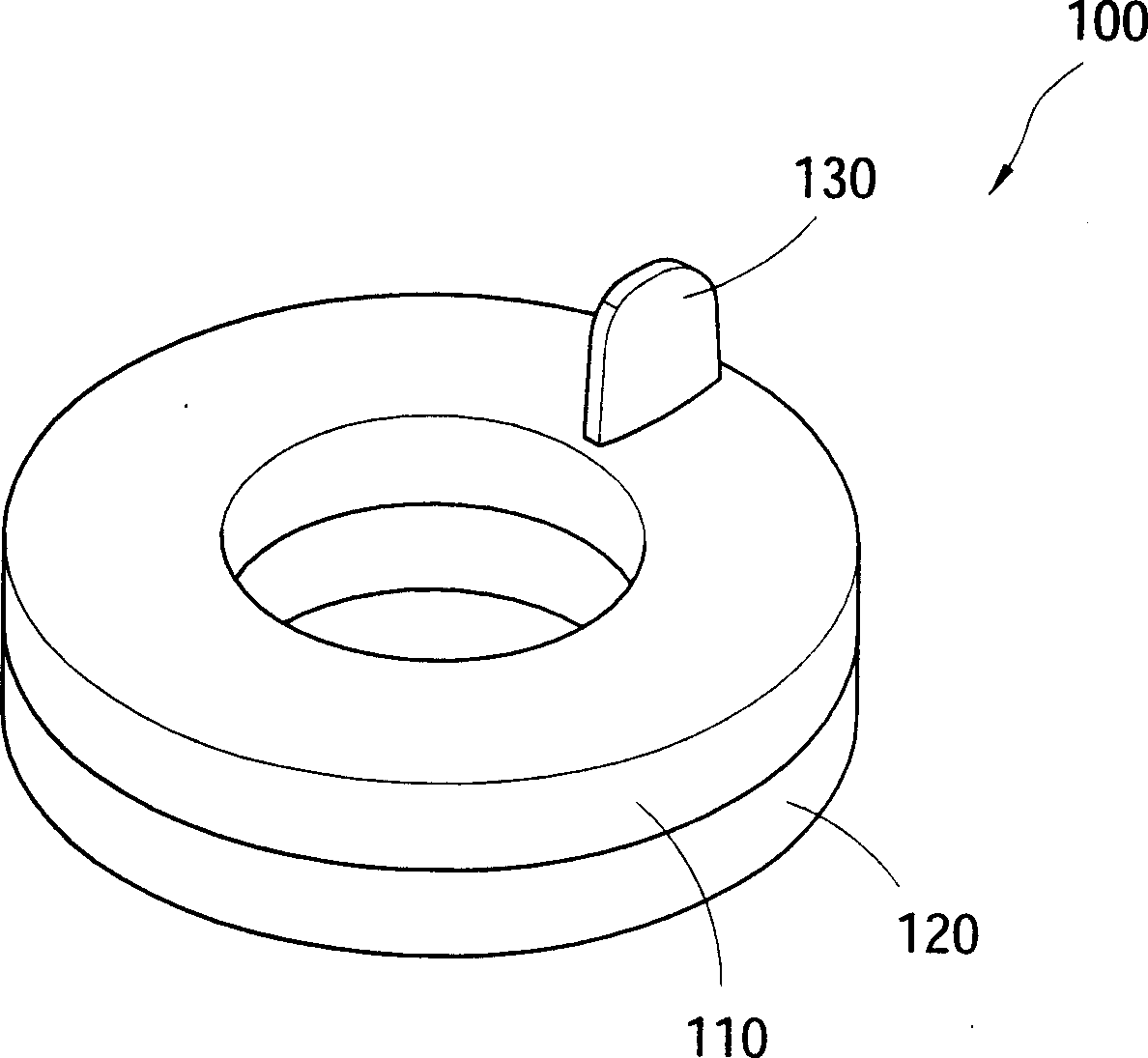

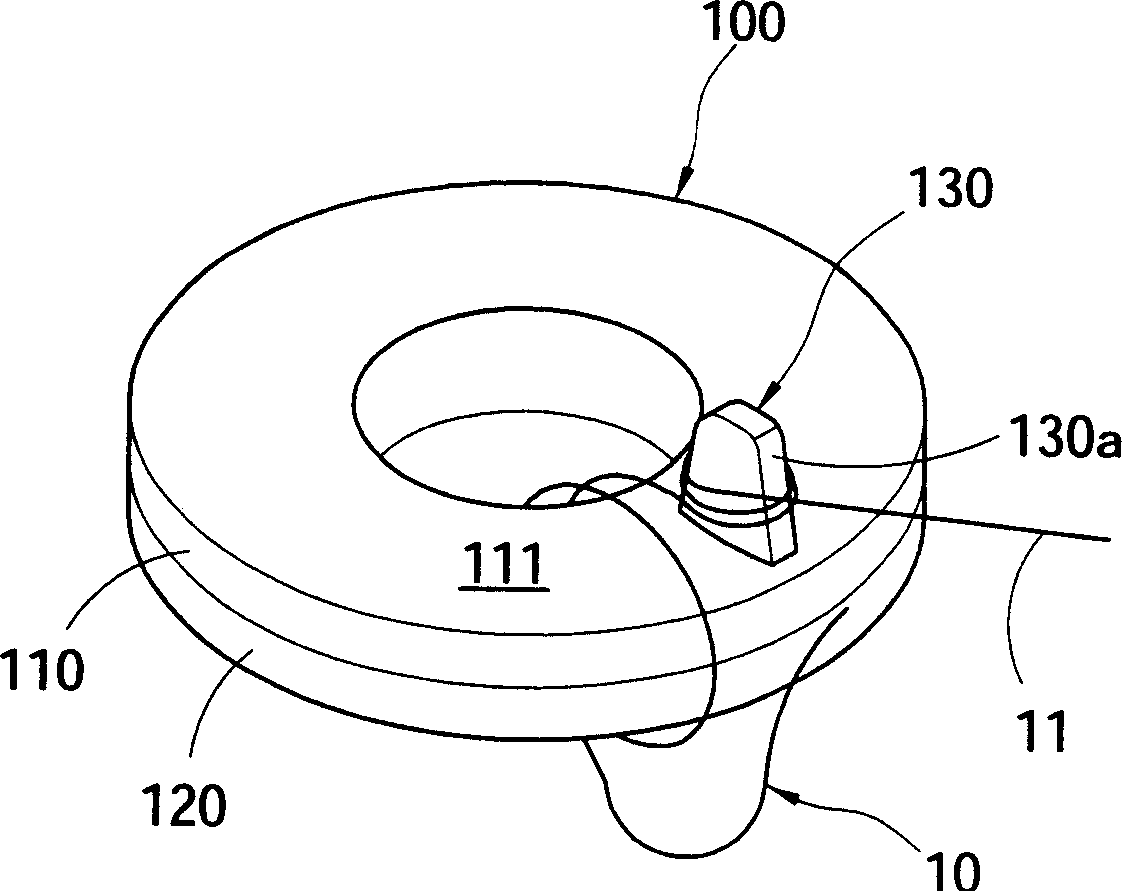

[0012] The present invention (as attached figure 1 , 2 As shown), the toroidal coil auxiliary winding frame 100 is mainly composed of two insulating covers 110, 120 and a starting wire end positioning block 130. The two insulating covers 110, 120 are used to cover an annular iron core (not shown), so as to provide insulation between the iron core and the enameled wire 10 (shown in subsequent figures); 110 and 120 are designed as separate components during manufacture, and the initial wire end positioning block 130 is detachably disposed on the outer surface 111 of the insulating cover 110 . The shape of the initial thread end positioning block 130 need not be limited, and it can be in the shape of a sheet, a cylinder, a cone, or a column.

[0013] In this embodiment, the design that the above-mentioned starting wire end positioning block 130 is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com