Filter net for liquid tank

A liquid tank and filter screen technology, applied in the field of liquid tanks, can solve the problems of difficulty in removing the wave absorbing plate, cumbersome assembly of the wave absorbing plate, and the need for operating experience, etc., and achieve the effect of suppressing fluctuations or center of gravity movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

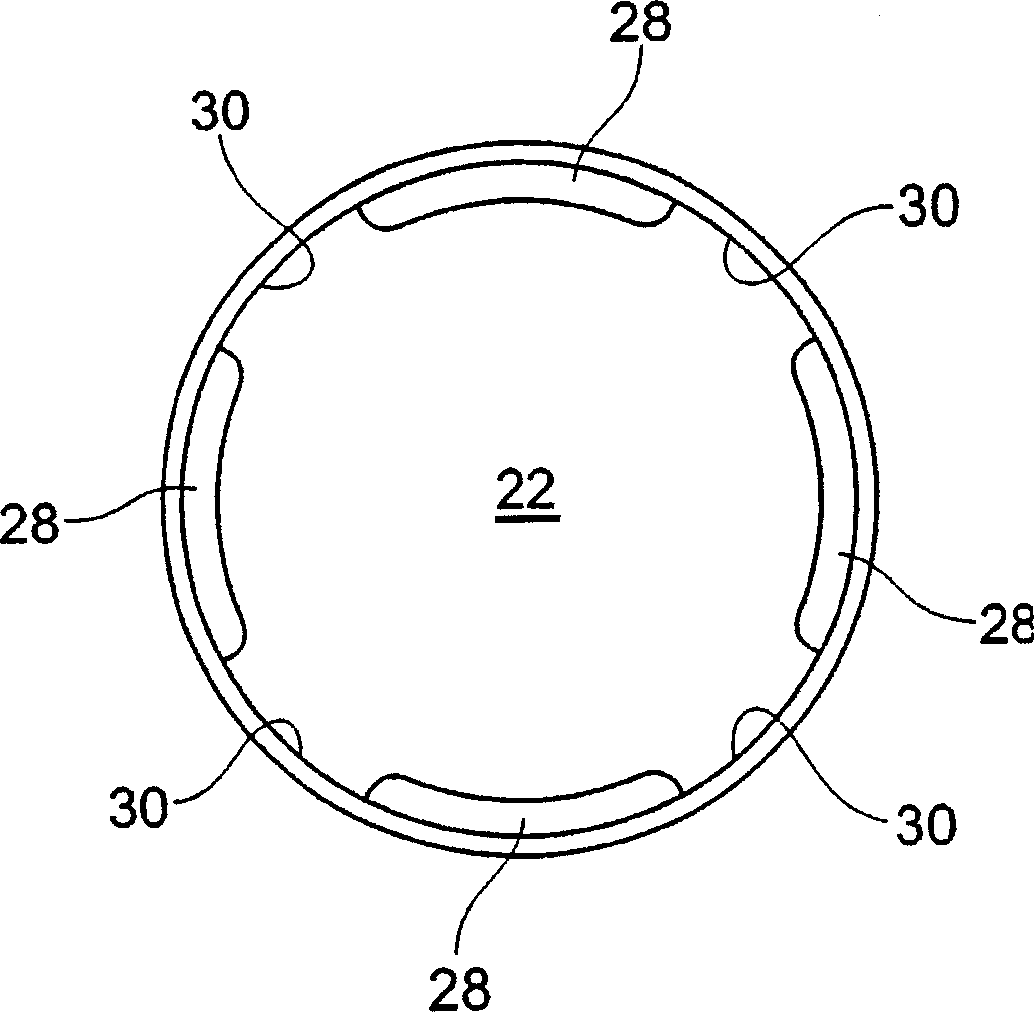

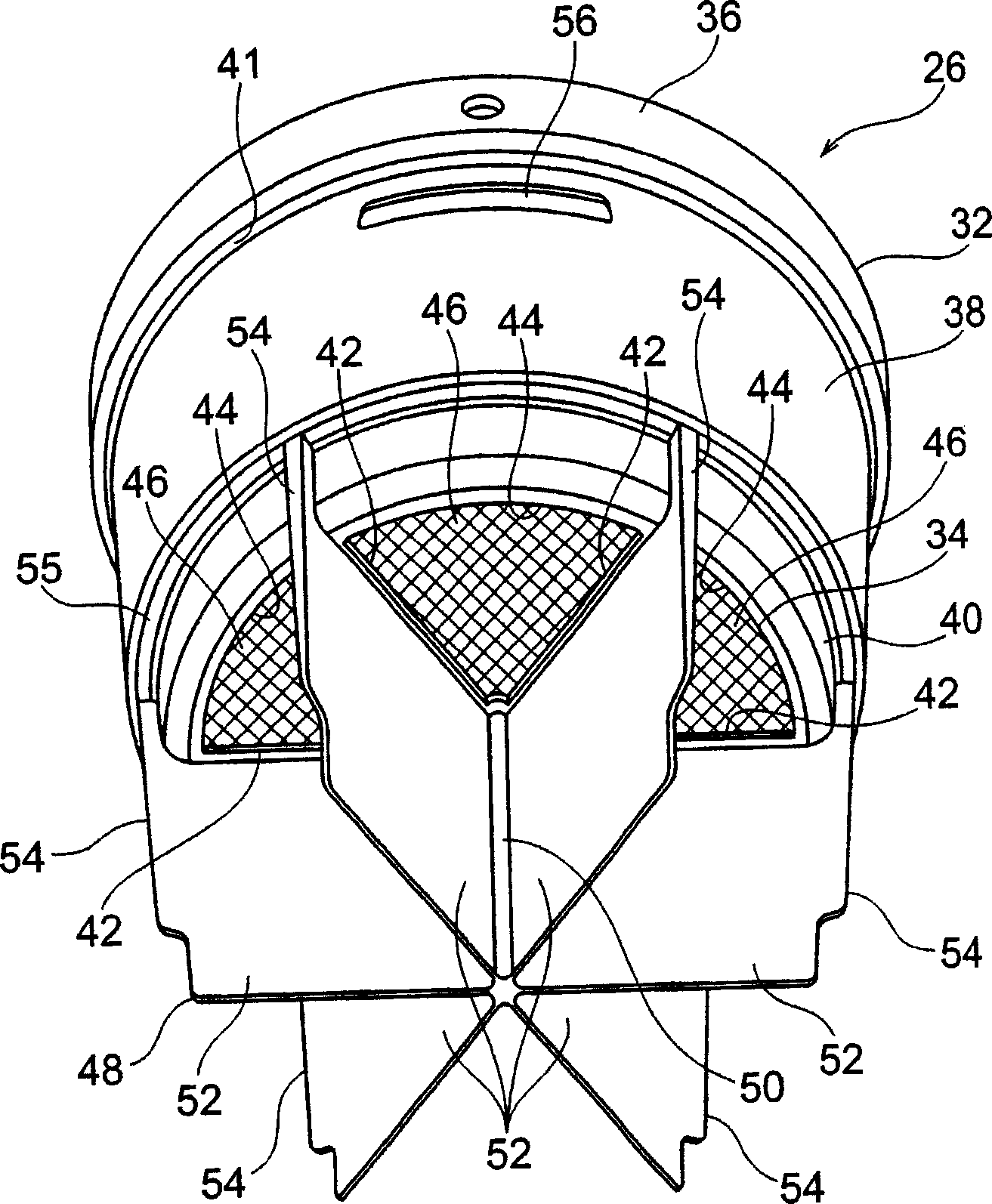

[0019] Next, preferred embodiments of the filter according to the present invention will be described with reference to the drawings. Among them, in this specification, words such as up and down, height and so on are preceded by figure 1 The status shown is used as a reference.

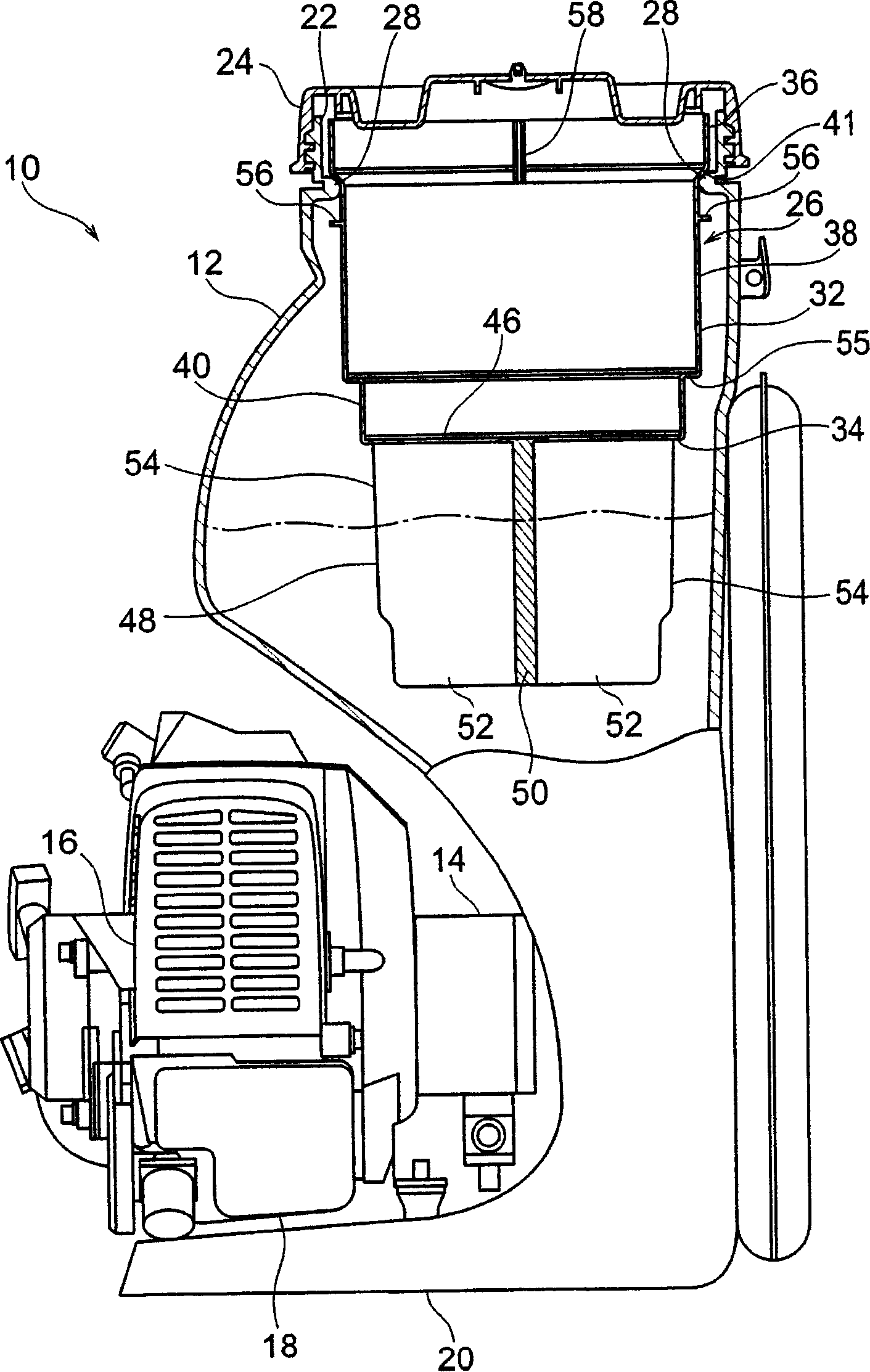

[0020] figure 1 It is a brief side view of a knapsack power sprayer that can be applied to the filter of the present invention placed on a horizontal plane, and a partial section shows the interior of the liquid tank. in, figure 1 The dotted line of is assumed to be the liquid level in the liquid tank. The illustrated knapsack power sprayer 10 includes: a liquid tank 12 for storing pesticides and other liquids, a pump 14 for sucking the liquid in the liquid tank 12 and pressurizing it to spray nozzles (not shown), and a pump 14 for driving the pump 14. An internal combustion engine 16 of a prime mover, and a fuel tank 18 for storing fuel of the internal combustion engine 16 . These are arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com