Wheel track-type crane position detection system

A detection system and crane technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve problems such as being easily affected by occlusion and vibration, ultrasonic beams cannot be irradiated, and cranes are not suitable for measurement, etc., achieving good application prospects and structure Simple, fast-transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

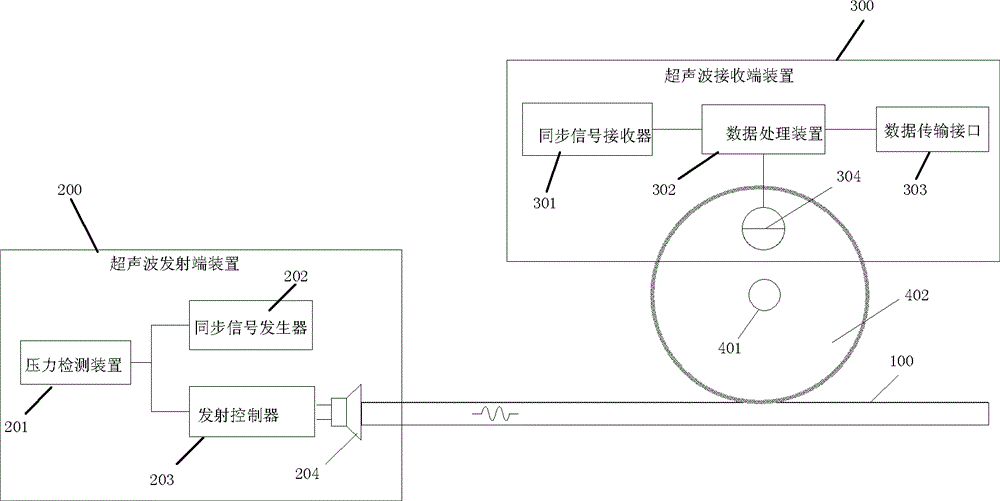

[0032] Such as figure 1 As shown, the wheel-rail crane position detection system of the present invention includes an ultrasonic transmitter device 200 arranged at the end of the track 100 and an ultrasonic receiver device 300 arranged on the traveling mechanism.

[0033]Wherein, the ultrasonic transmitter device 200 is composed of a pressure detection device 201 , a synchronous signal generator 202 , a transmitter controller 203 and an ultrasonic transmitter 204 . The pressure detection device 201 is respectively connected to a synchronous signal generator 202 and a transmission controller 203 , and the transmission controller 203 is connected to an ultrasonic transmitter 204 .

[0034] The pressure detection device 201 is a pressure sensor or a push switch or a piezoelectric film, which is used to generate a trigger signal to trigger the ultrasonic transmitter 204 and the synchronization signal generator 202 at the same time. The ultrasonic transmitter 204 is used to emit u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com