Drain socket and flush toilet

A toilet and flushing technology, which is applied in flushing toilets, water supply devices, buildings, etc., can solve problems such as pipe blockage, dirt is difficult to pass through, and siphoning is insufficient, so as to prevent dirt from clogging, reduce the contact area, The effect of reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] Hereinafter, embodiments of the present invention will be described based on the drawings.

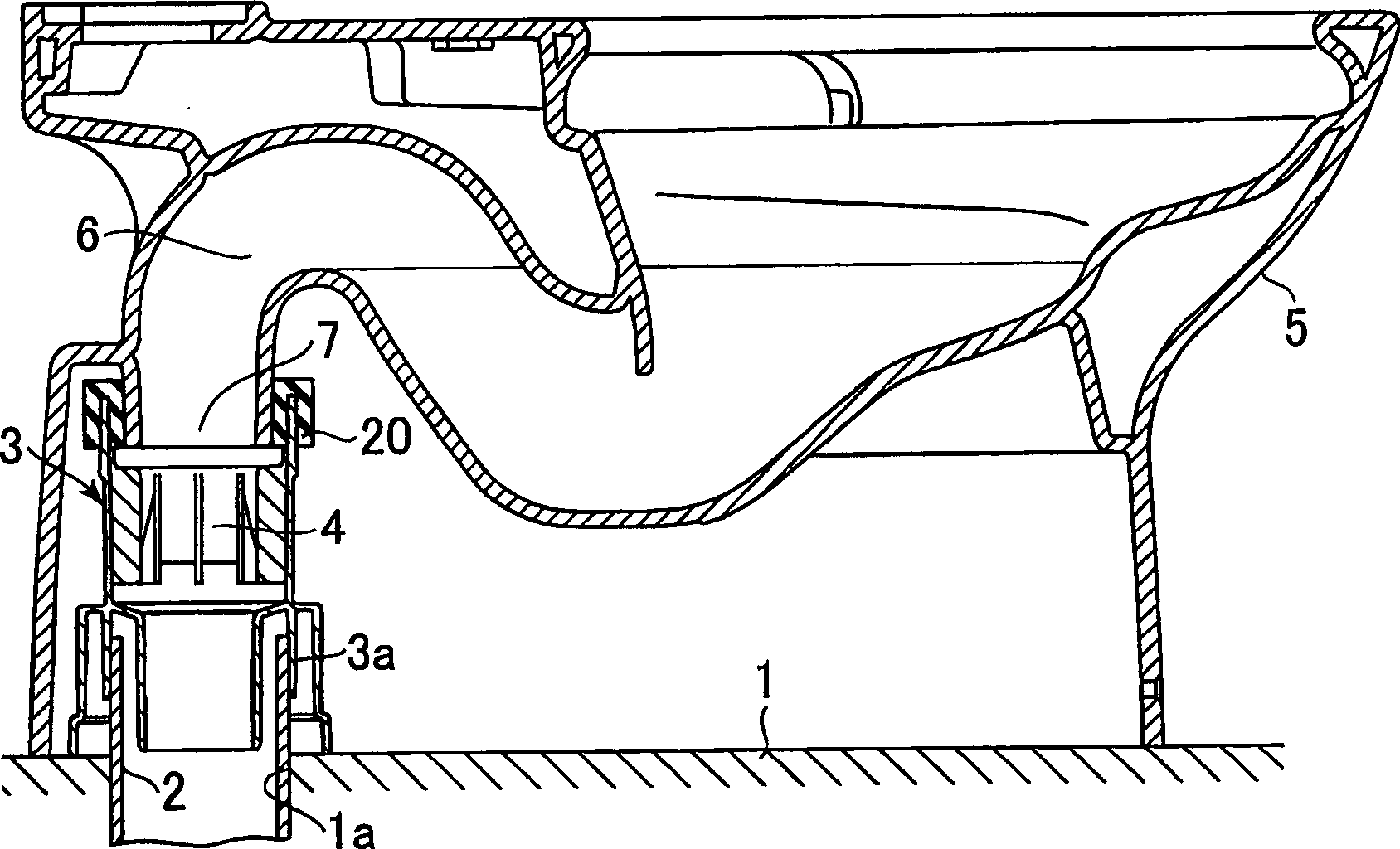

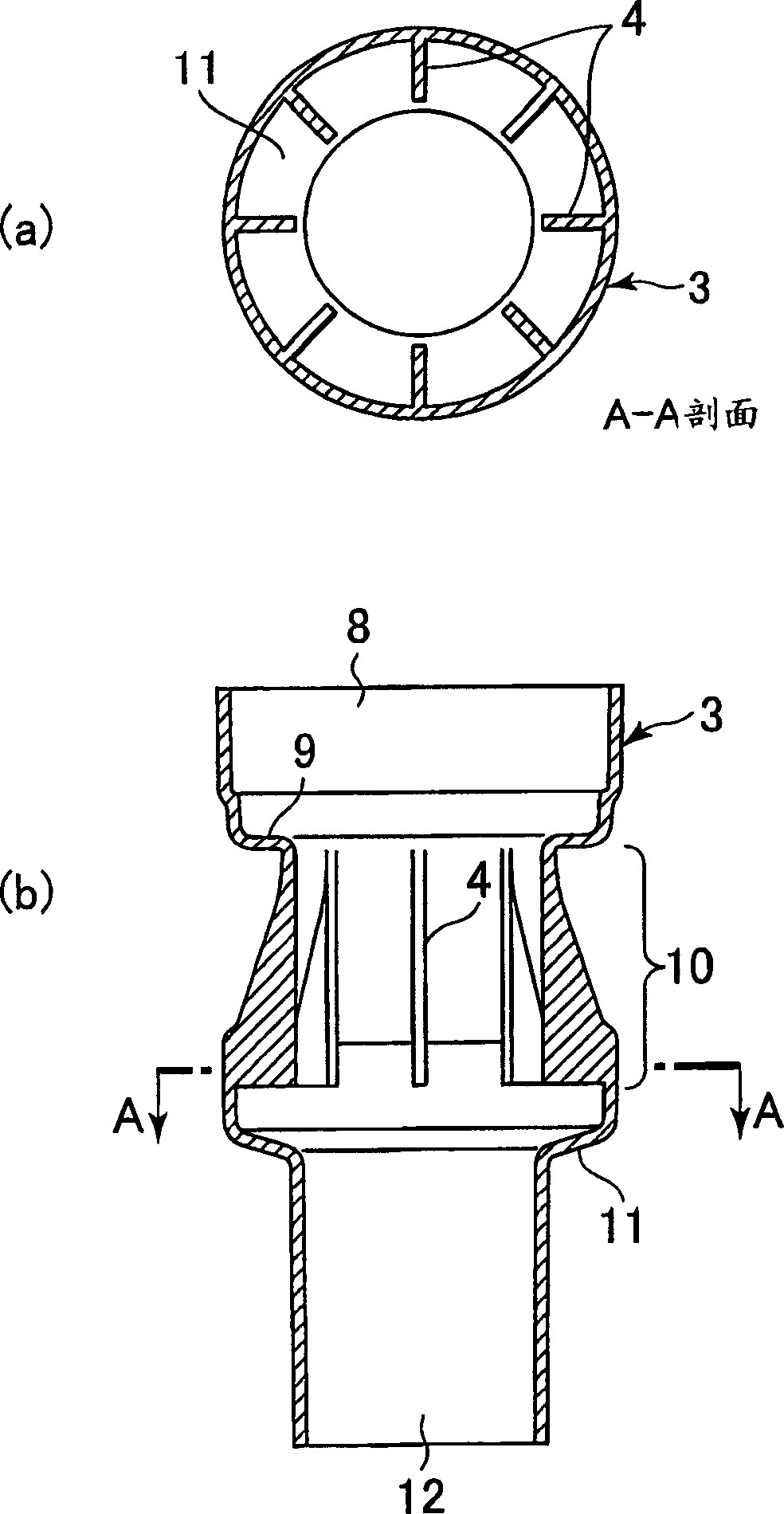

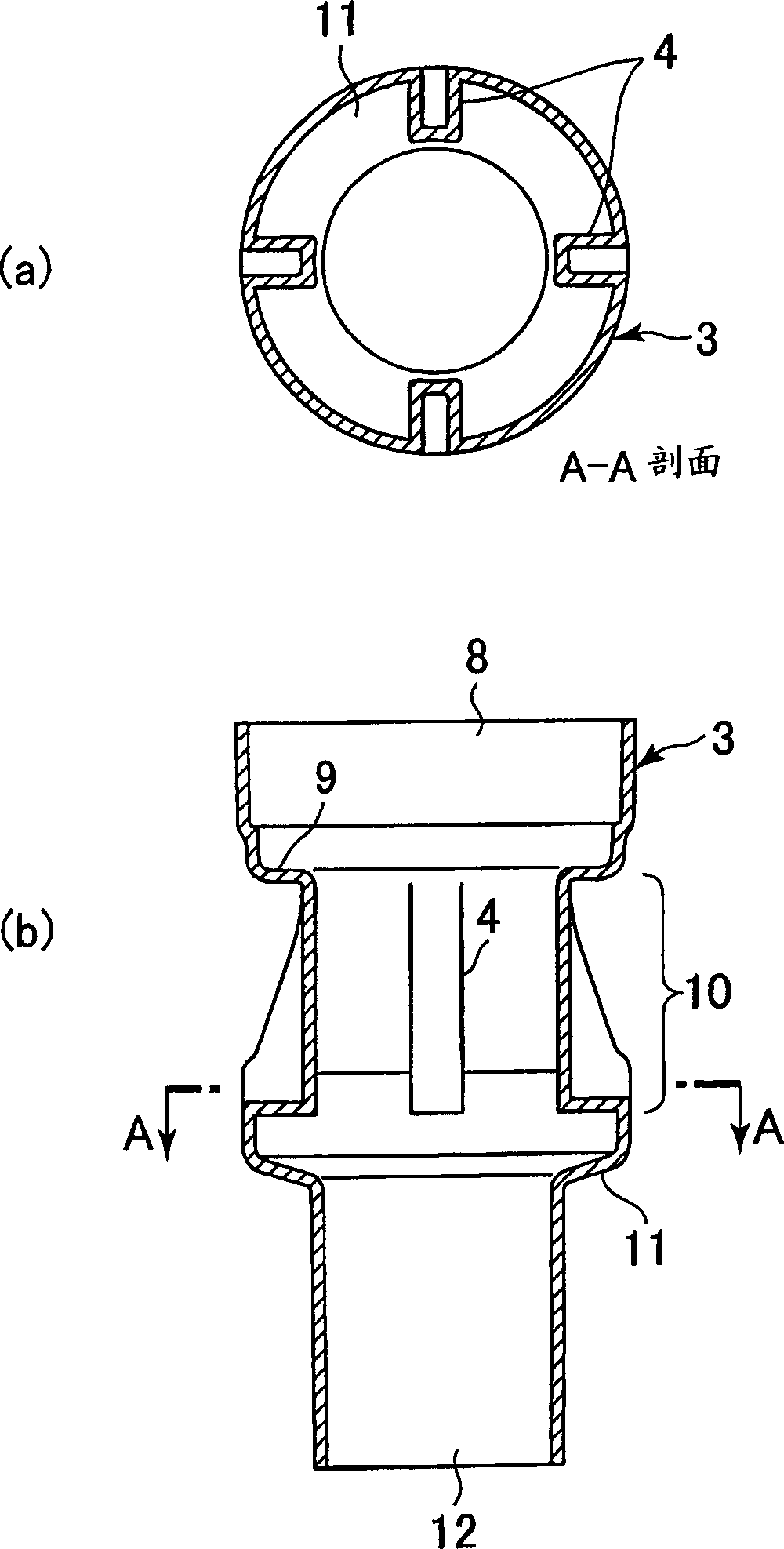

[0081] figure 1 It is a longitudinal sectional view showing the connection structure of the drain pedestal, the flush toilet body and the drainpipe according to the first embodiment of the present invention, figure 2 for will be with figure 1 It is an enlarged view of the main part cut off of the connection structure of the drain pipe of the drain seat part.

[0082] exist figure 1 Among them, the drain pipe 2 stands up from the hole 1a provided on the floor 1. On the drainpipe 2, a drain socket body 3 is watertightly fixed, and the drain socket body 3 is watertightly fixed to the outlet 7 of the elbow drainage channel 6 of the flush toilet body 5 installed on the floor 1. superior. In addition, the connection between the drain socket body 3 and the drain pipe 2 is performed through the connection portion 3a of the drain socket. A portion having a plurality of inner and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com