Method for producing bone marrow condiment

A technology of condiment and preparation method, applied in food preparation, application, food science and other directions, can solve the problems of low calcium content, no calcium supplementation, low nutritional value, etc., and achieve the effect of extending shelf life and facilitating packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

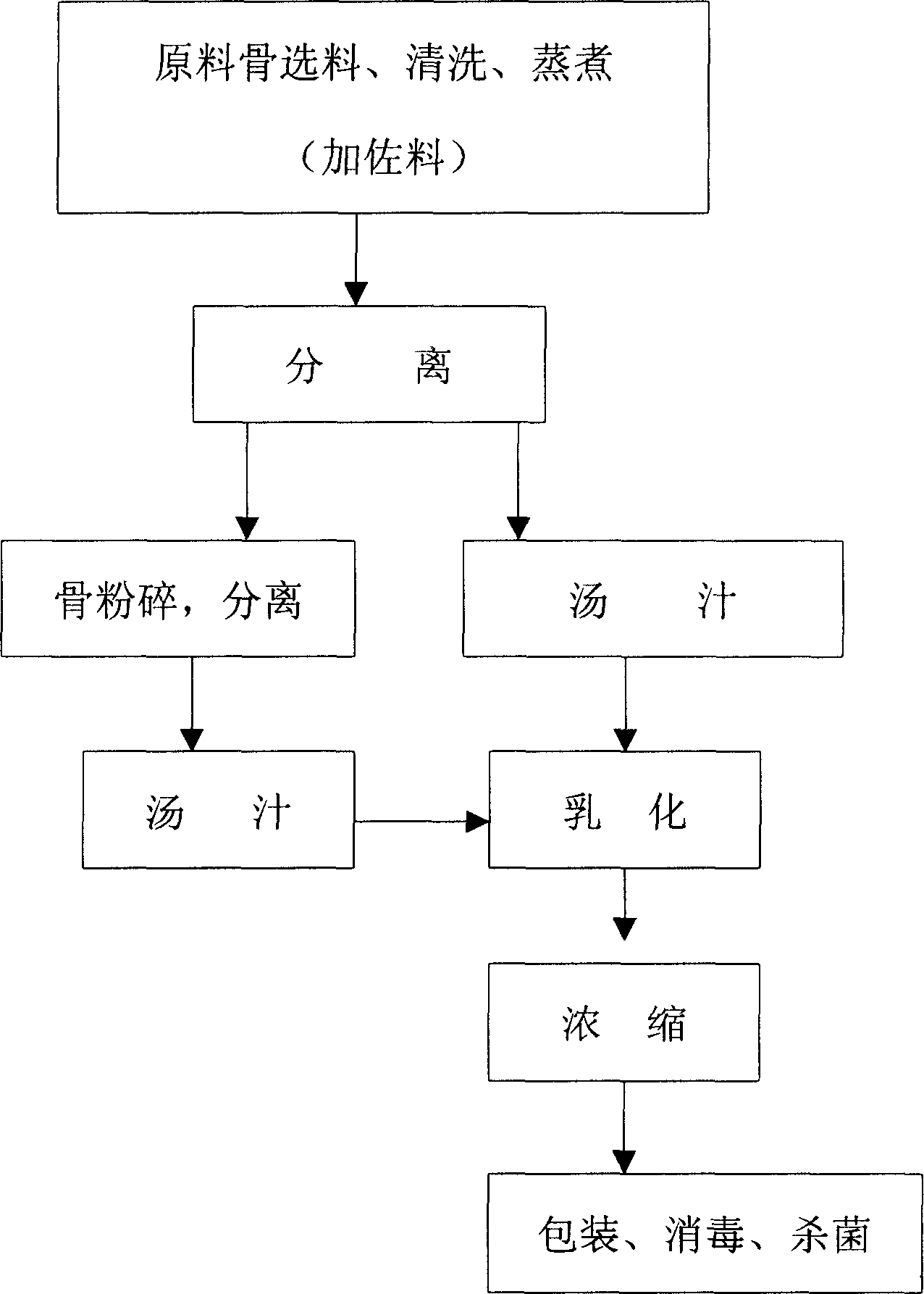

Method used

Image

Examples

Embodiment

[0018] 1. Select 100kg of fresh or refrigerated beef hard bones with attached meat. Generally, the attached meat accounts for 5-10% of the bone weight. Clean them, put them into a pressure cooker, and add 120kg of water. At the same time, add 200g each of nutmeg, clove, Chinese prickly ash, pepper, 2kg onion, and 2kg salt. Steam it at a temperature of 120°±5°C and a pressure of 0.2Mpa for 45 minutes. Seasonings, etc. should be wrapped in cloth.

[0019] 2. After stopping the temperature, stir to separate the meat with bones from the bones, and keep the soup.

[0020] 3. Crush the bone with a hammer mill into pieces below 10 mm, add 40 kg of water to boil (under normal pressure) and stir, and separate the bone marrow and juice remaining in the original bone cavity.

[0021] 4. Put the soup separated twice into the colloid mill to pulverize and emulsify.

[0022] 5. Concentrate the emulsion in the concentrator, the double-effect vacuum concentration parameters are I.68°C, 600mm...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap