Refrigeration storage warehouse

A technology for storage and refrigerant, which is applied to household refrigeration devices, defrosting, household appliances, etc. It can solve the problems of adverse effects on the cooling capacity of the storage room and the increase in the time required for defrosting, so as to promote the melting and refrigeration of frost. Ability deterioration suppression, effect of shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

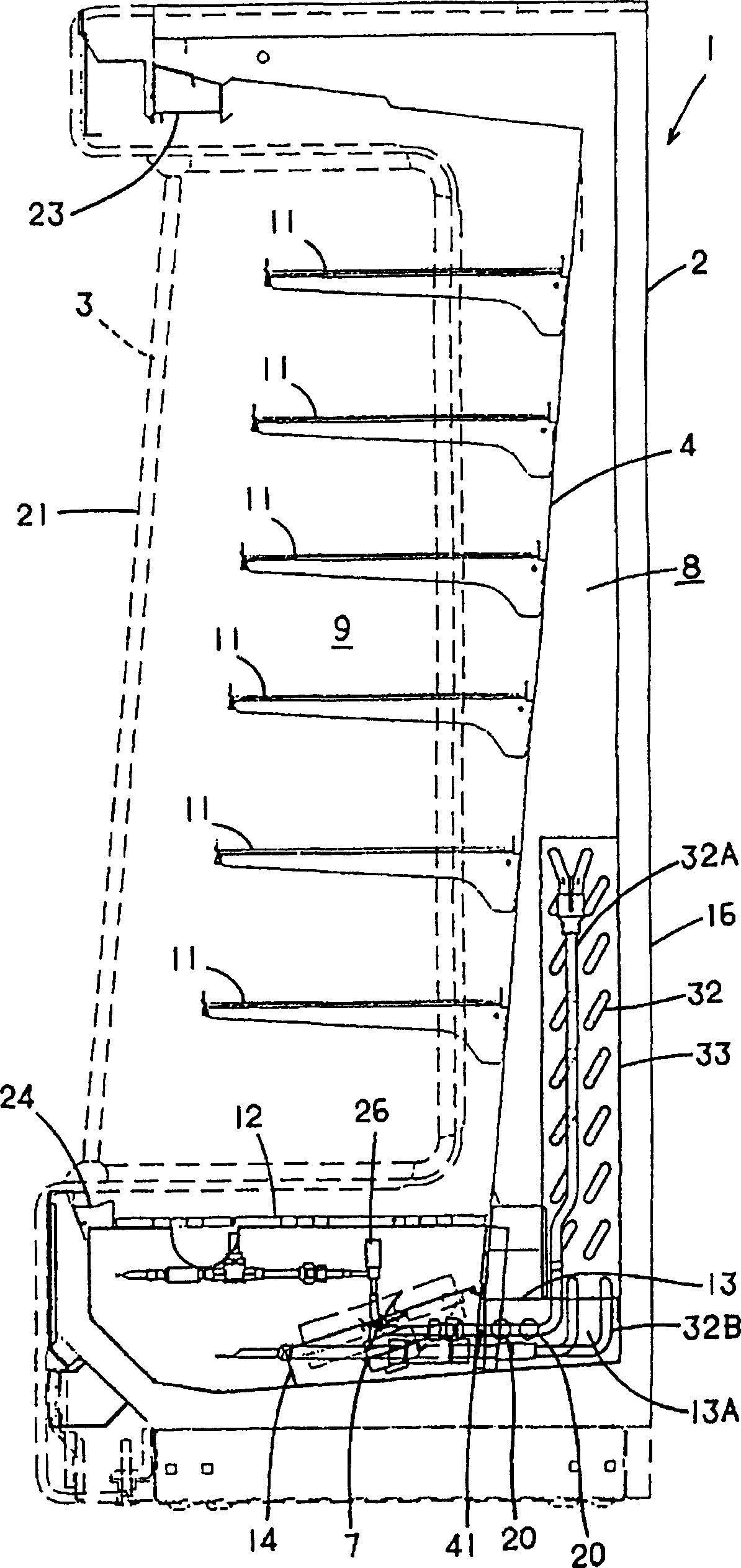

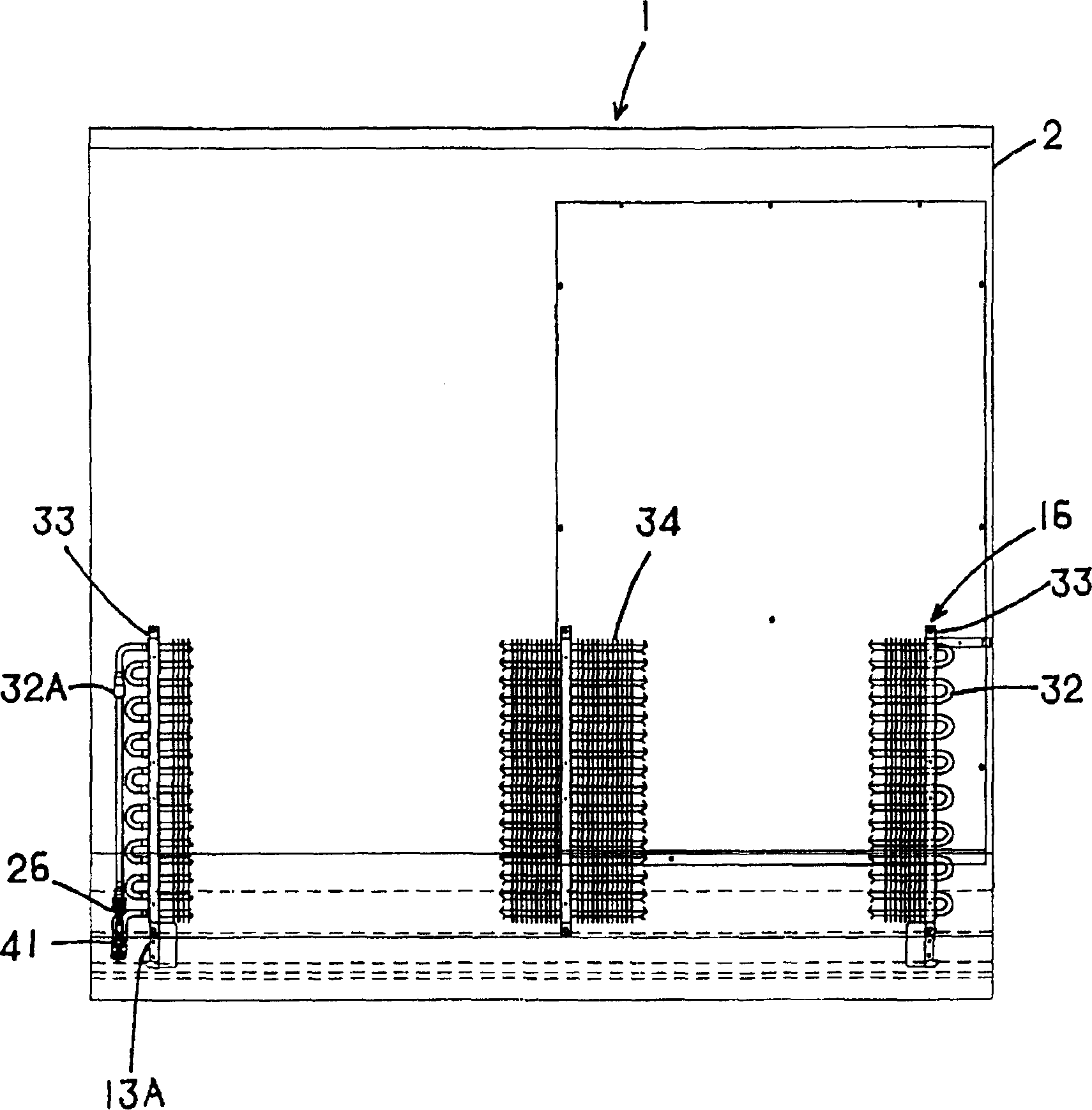

[0031] figure 1 It is a longitudinal sectional side view of a low-temperature showcase 1 as an embodiment of the refrigeration storage of the present invention; figure 2 is the perspective back view of the low temperature showcase 1; image 3 It is a plan view of the evaporator 16 part of the low temperature showcase 1. The low-temperature showcase 1 of the embodiment is a vertical open showcase installed in stores such as convenience stores and supermarkets. side panel 3. There is a space inside the heat insulating wall 2 and a partition 4 is installed. A pipe 8 is formed between the heat insulating wall 2 and the partition 4. The inside of the partition 4 forms a storage room 9 as a cooled space.

[0032] In this storage room 9, multi-layer shelves 11 are set up ..., and a pedestal 12 is installed at the bottom of the storage room 9 at the same time. An evaporator 16 constituting a refrigerant circuit of the refrigeration device is arranged vertically. Between the fan ...

Embodiment 2

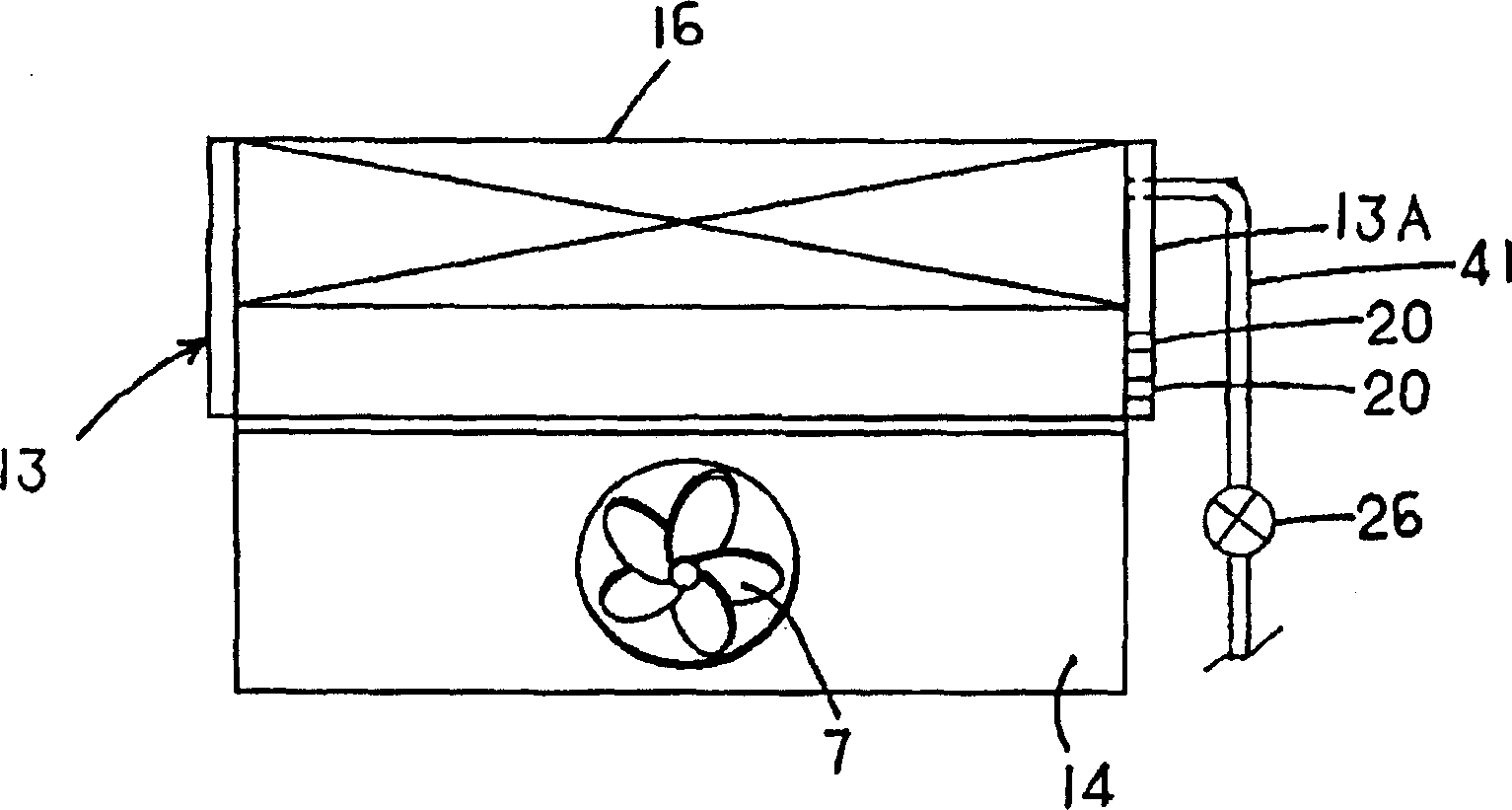

[0047] Figure 4 represents another embodiment of the present invention. In this case, the outlet pipe 41 of the expansion valve 26 is introduced into the evaporator lower cover 13 (constituting a pipe) from the blowing side of the blower 7 to the evaporator 16 . Thus, by arranging the outlet pipe 41 in the duct from the outlet side of the blower 7 to the evaporator 16, the outlet pipe 41 of the expansion valve 26 is exposed to the wind from the blower 7, and the adhering frost can be effectively melted during defrosting.

Embodiment 3

[0049] Figure 5 Still another embodiment of the present invention is shown. In this case, an outlet pipe 41 of the expansion valve 26 is disposed on the upper air outflow side of the evaporator 16 . In this way, if the outlet pipe 41 is arranged on the air outflow side of the evaporator 16, the cold air dried through the evaporator 16 during cooling operation is blown onto the outlet pipe 41 of the expansion valve 26, and the adhesion of frost to the outlet pipe 41 can be suppressed. In addition, since the outlet pipe 41 of the expansion valve 26 is exposed to the wind from the blower 7 during the defrosting operation, it is possible to efficiently defrost the outlet pipe 41 where frost is most likely to adhere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com