Straight arm self-propelled high-altitude operating platform

A kind of high-altitude work platform, self-propelled technology, applied in the direction of lifting device, etc., can solve the problems that the working range of the working platform cannot reach the working range, the overturning moment of the telescopic arm is small, and the chassis has no expansion function, so as to improve reliability and safety , large overturning moment and large floor area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

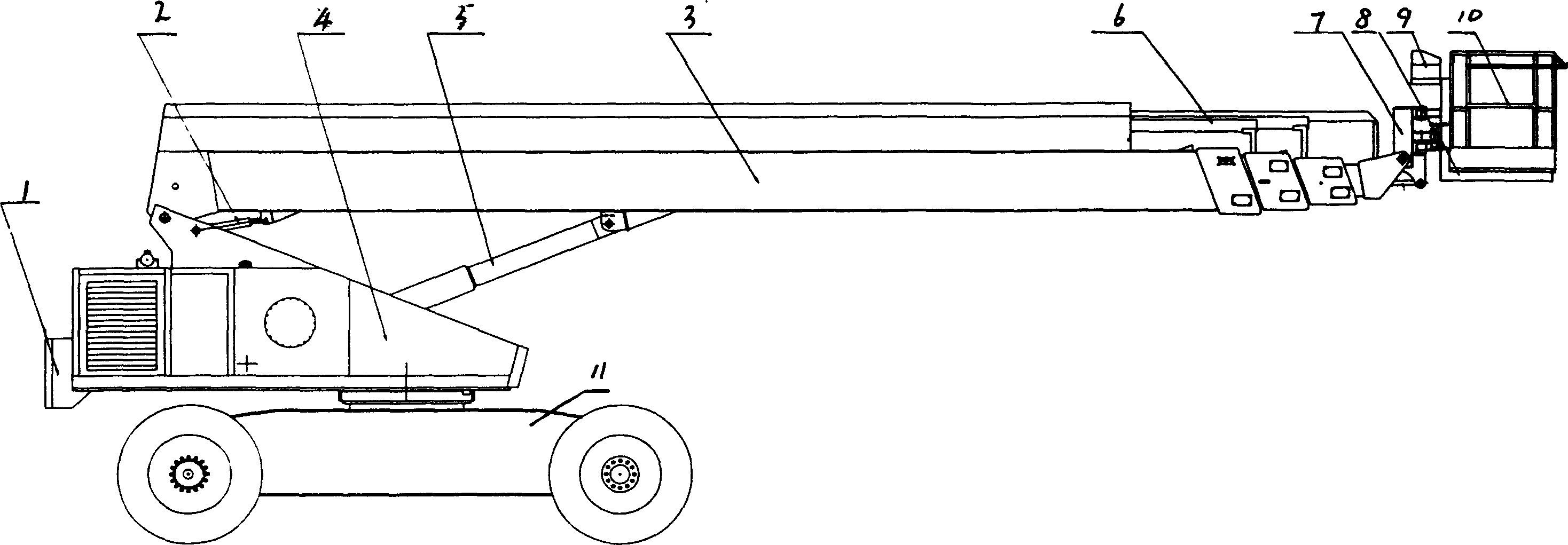

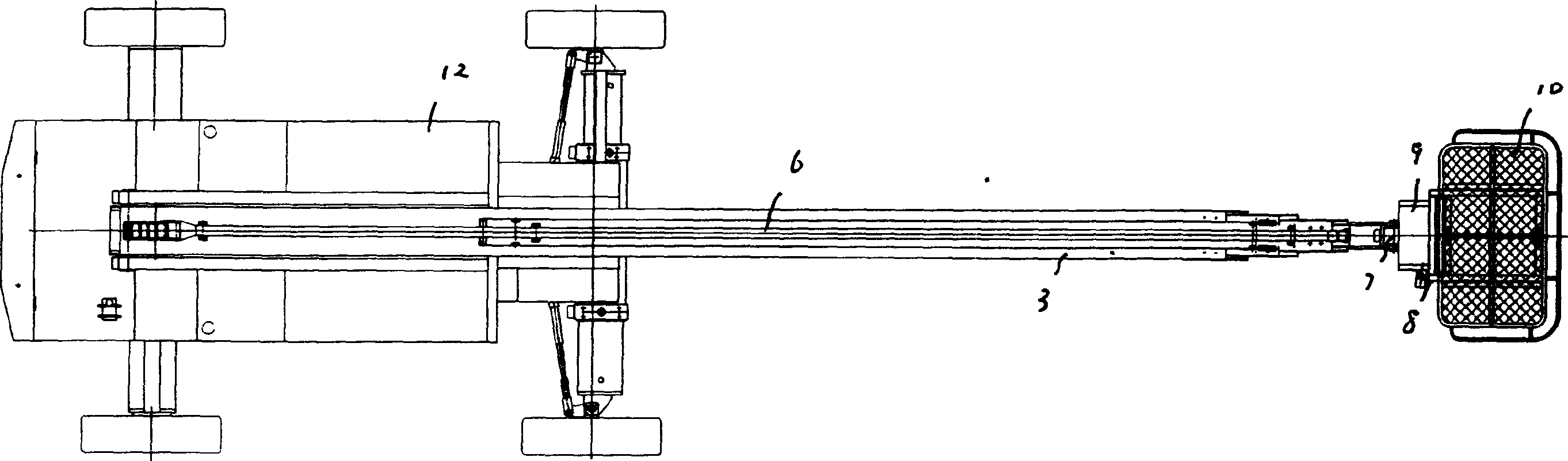

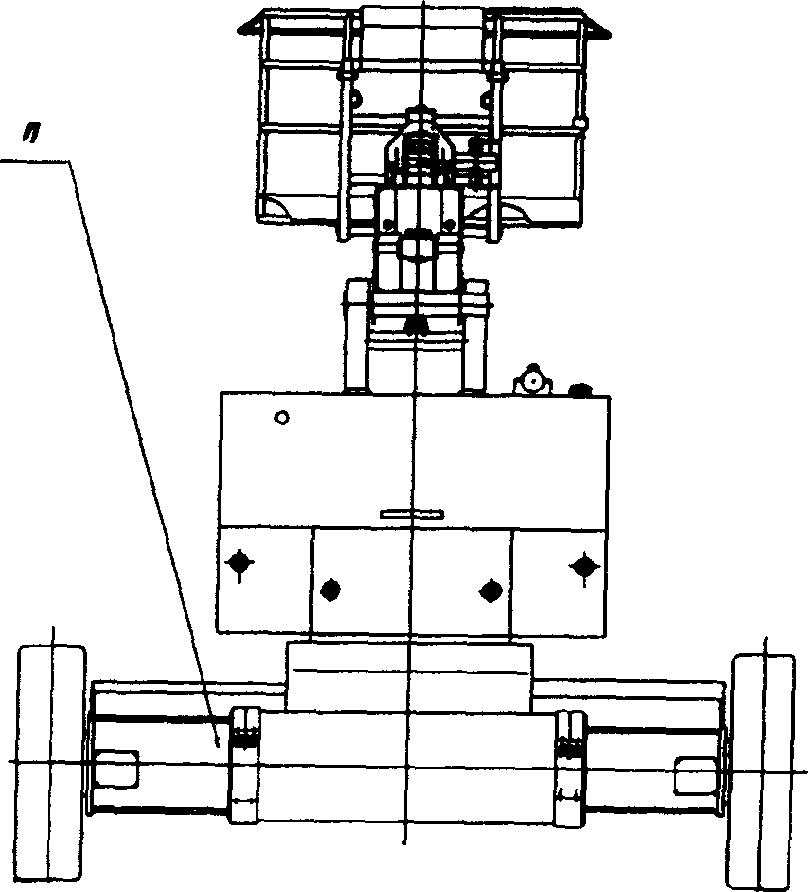

[0027] see Figure 1~3 , the invention is a straight-arm self-propelled aerial work platform. It mainly consists of counterweight 1, rear balance cylinder 2, telescopic arm 3, slewing platform 4, luffing cylinder 5, drag chain mechanism 6, goose head 7, L-shaped bracket 8, upper operation box 9, working bucket 10 and walking chassis 11 and so on.

[0028] The said slewing platform 4 is arranged on the walking chassis 11 and can turn 360 degrees in any direction.

[0029] The rear end of the telescopic arm 3 is hinged to the slewing platform 4, and the front end is hinged to the goose head 7 through the front balancing oil cylinder. The L-shaped bracket 8 is connected to the goose head 7, and the working bucket 10 is placed on the L-shaped bracket 8. The upper operation box 9 is arranged on one side of the L-shaped support 8 . The drag chain mechanism 6 is relocated on the telescopic arm 3 .

[0030] The rear balance oil cylinder 2 is fixedly connected to the rotary platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com