Shock-absorbing component used for package of vacuum sweeper

A technology for vacuum cleaners and packaging, which is applied in the field of shock-absorbing components for packaging, which can solve the problems of increased production costs and complicated operating procedures, and achieve the effects of preventing damage, improving operating efficiency, and preventing component damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

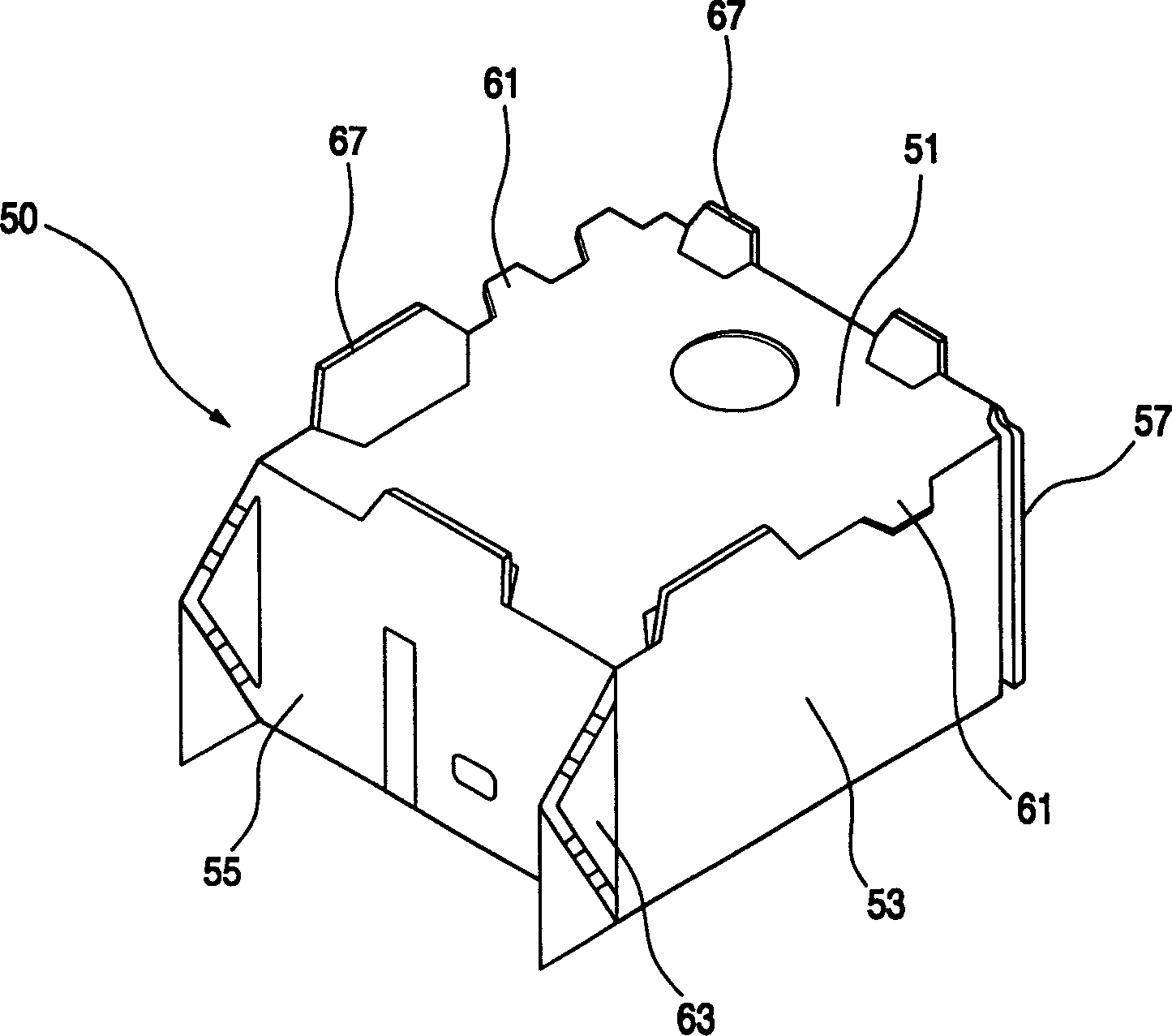

[0039] An embodiment of a shock-absorbing member for packaging of a vacuum cleaner of the present invention as described above will be described in detail below with reference to the accompanying drawings.

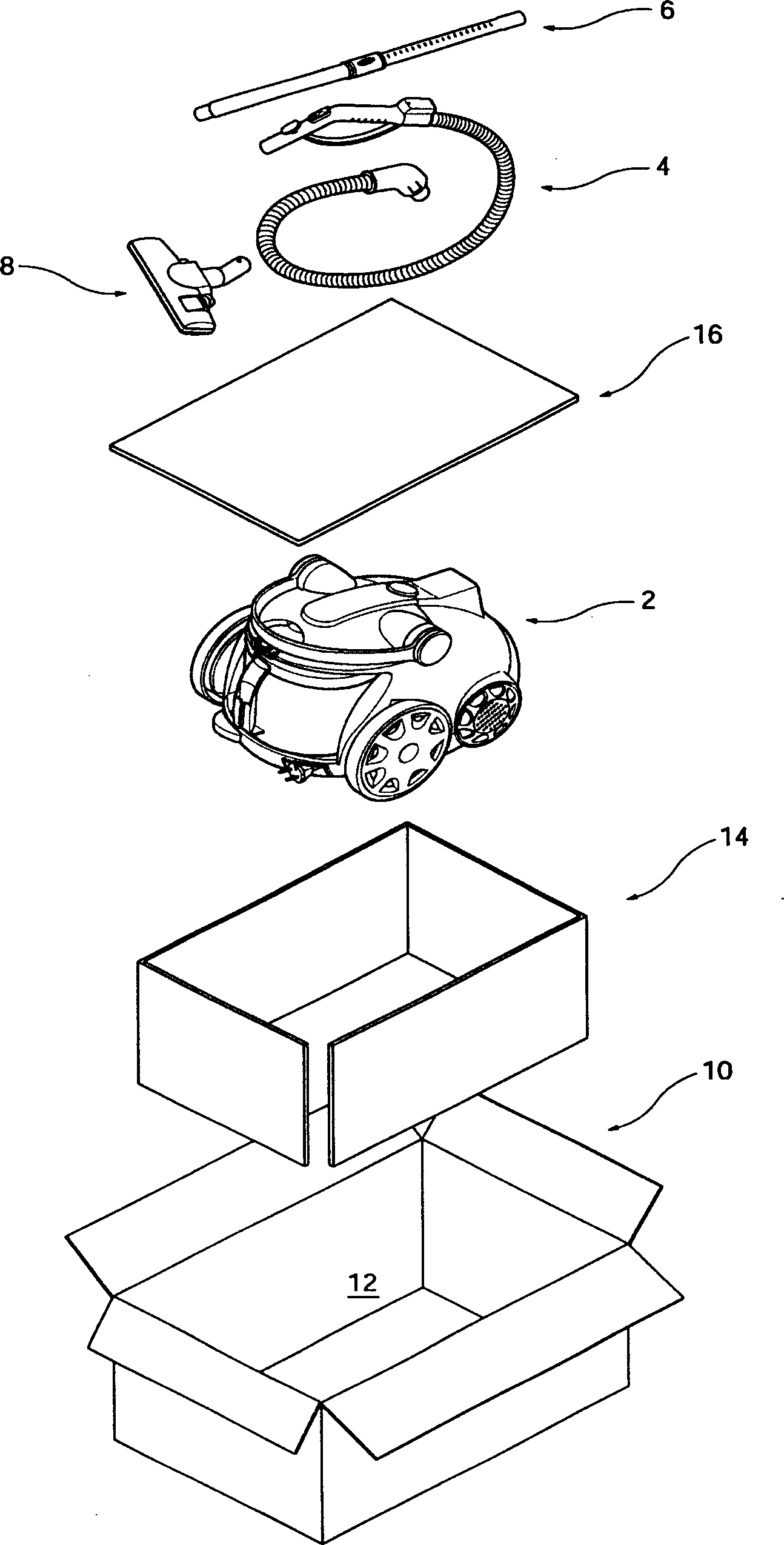

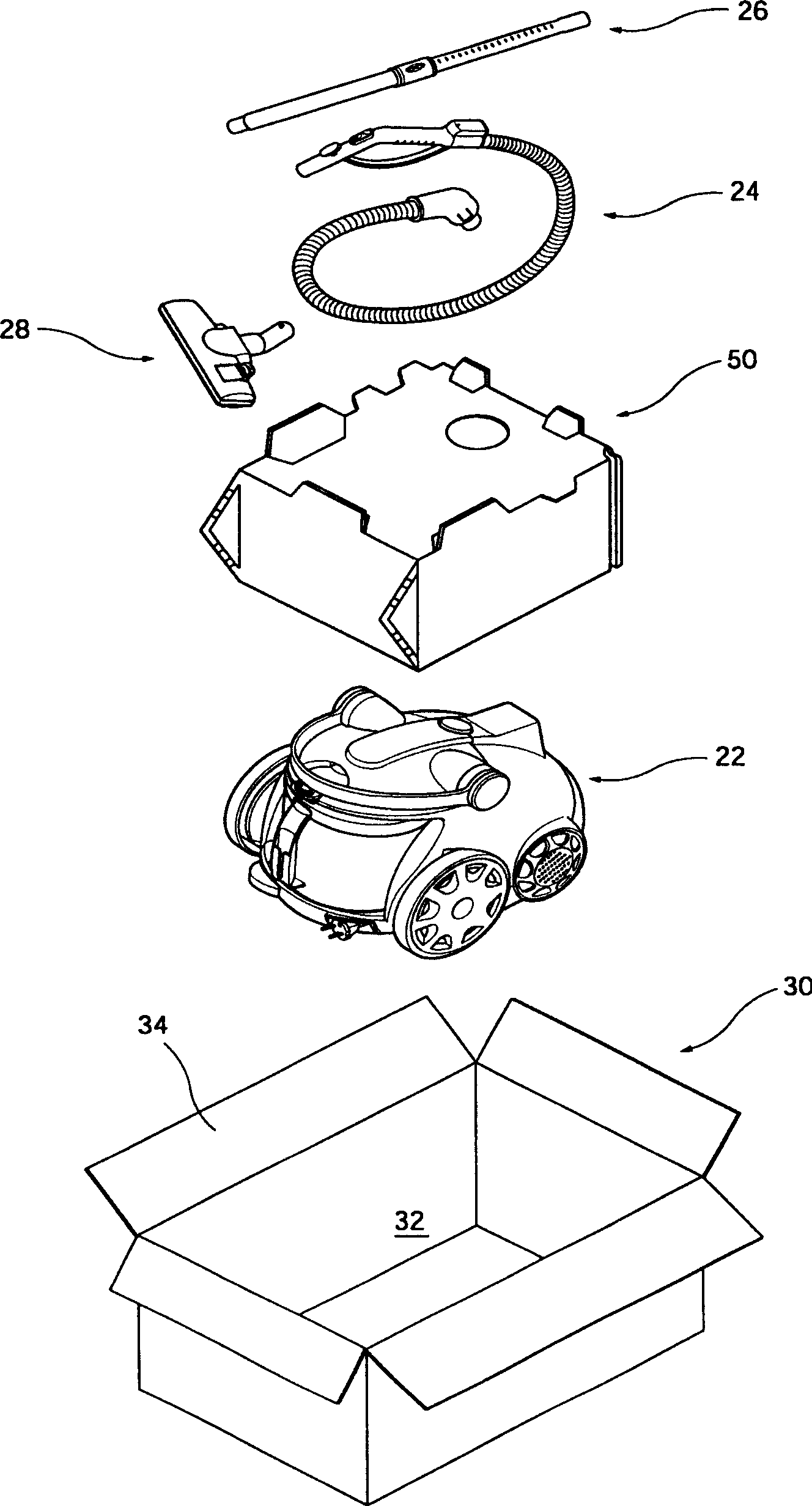

[0040] figure 2 It is an exploded side view showing a packaged state of a vacuum cleaner using the shock-absorbing member for packaging of a vacuum cleaner according to the present invention, image 3 shows the assembled state of one embodiment of the shock absorbing component of the present invention, Figure 4 for image 3 Expanded view of the shock absorbing components shown, Figure 5 It shows the state when the shock-absorbing component of the present invention is put into the packing box.

[0041] As shown in the figure, the vacuum cleaner includes the following components, namely: a vacuum cleaner body 22, which is equipped with a dust collection box capable of filtering foreign matter sucked out; a connecting hose 24, which is made of a material with certain fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com