Dry-wet mixed granulation unit

A wet granulator and mixing technology, which is applied in the direction of making medicines into special physical or ingestible devices, can solve the problems of dust flying and spreading of materials, threats to workers' health, pollution of the working environment, etc., and achieve the degree of automation High, the effect of protecting the health of workers and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

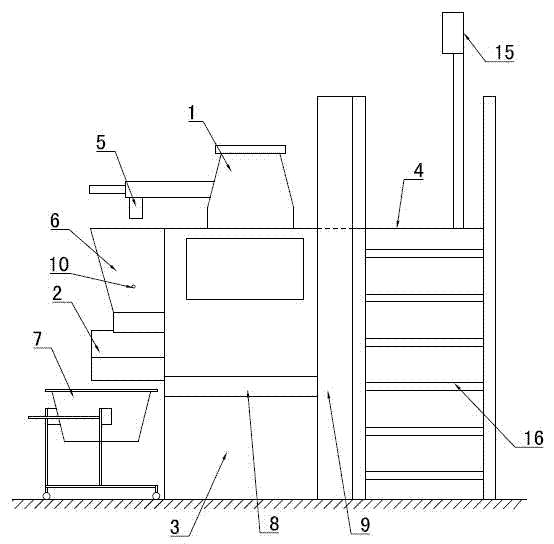

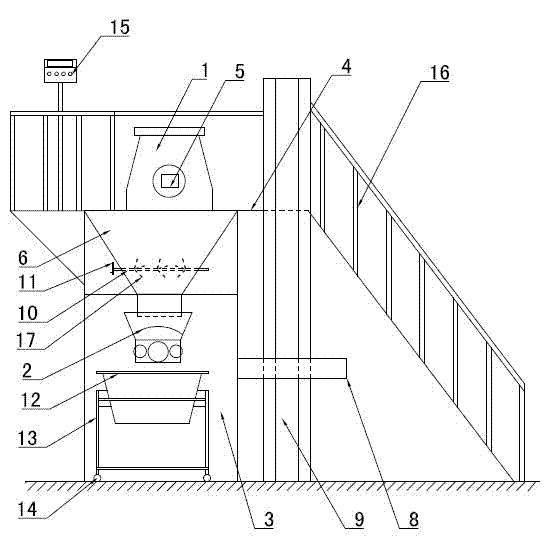

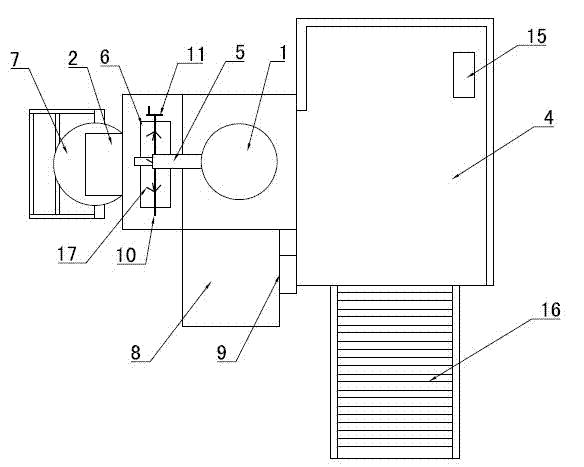

[0018] Refer to attached Figure 1~3 : The dry-wet mixing granulation unit includes a wet granulator 1, a granulator 2, a base 3, a working platform 4, a stirring funnel 6 and a boiling drying pot 7, the base 3 is a hexahedron with regular shape, and the wet granulator 1 is fixed on the upper end plane of the hexahedron. A lifting device is installed close to the base 3, and a working platform 4 with an escalator 16 is installed on the right side of the wet granulator 1 and the lifting device. The lifting device includes a lifting platform 8 and a hydraulic lifting column 9. The cross section of the lifting platform 8 is rectangular , can slide up and down, installed on one side of the base 3, fixedly install the hydraulic lifting column 9 on the side of the lifting platform 8 close to the working platform 4, the raw material barrel is placed on the lifting platform 8, and is realized under the action of the hydraulic lifting column 9 Hydraulic take-off and landing, automatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com