Shroud and blower using the same

A technology of blower and shield, applied in the field of axial flow blower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments of the present invention will be described herein with reference to the accompanying drawings.

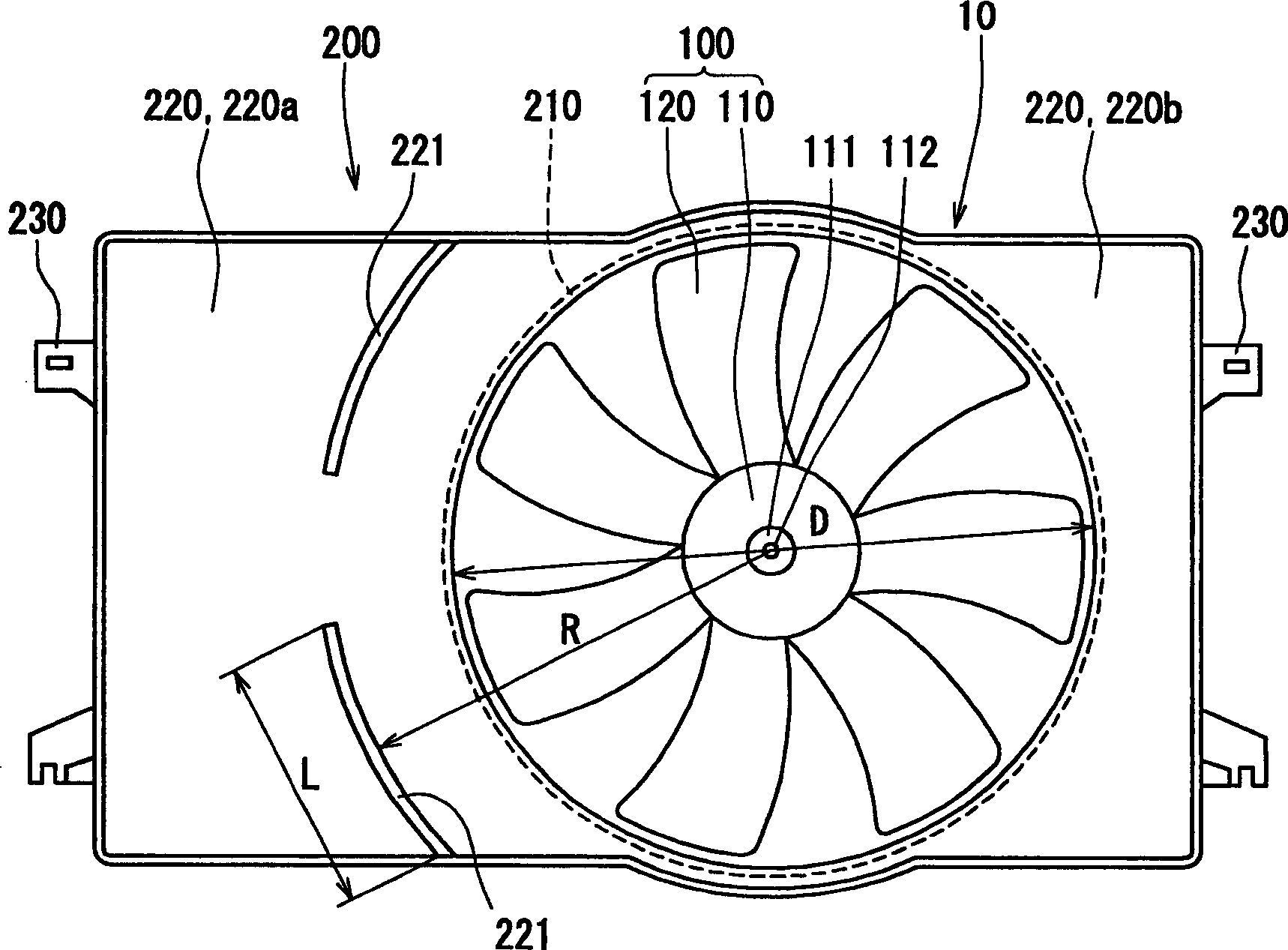

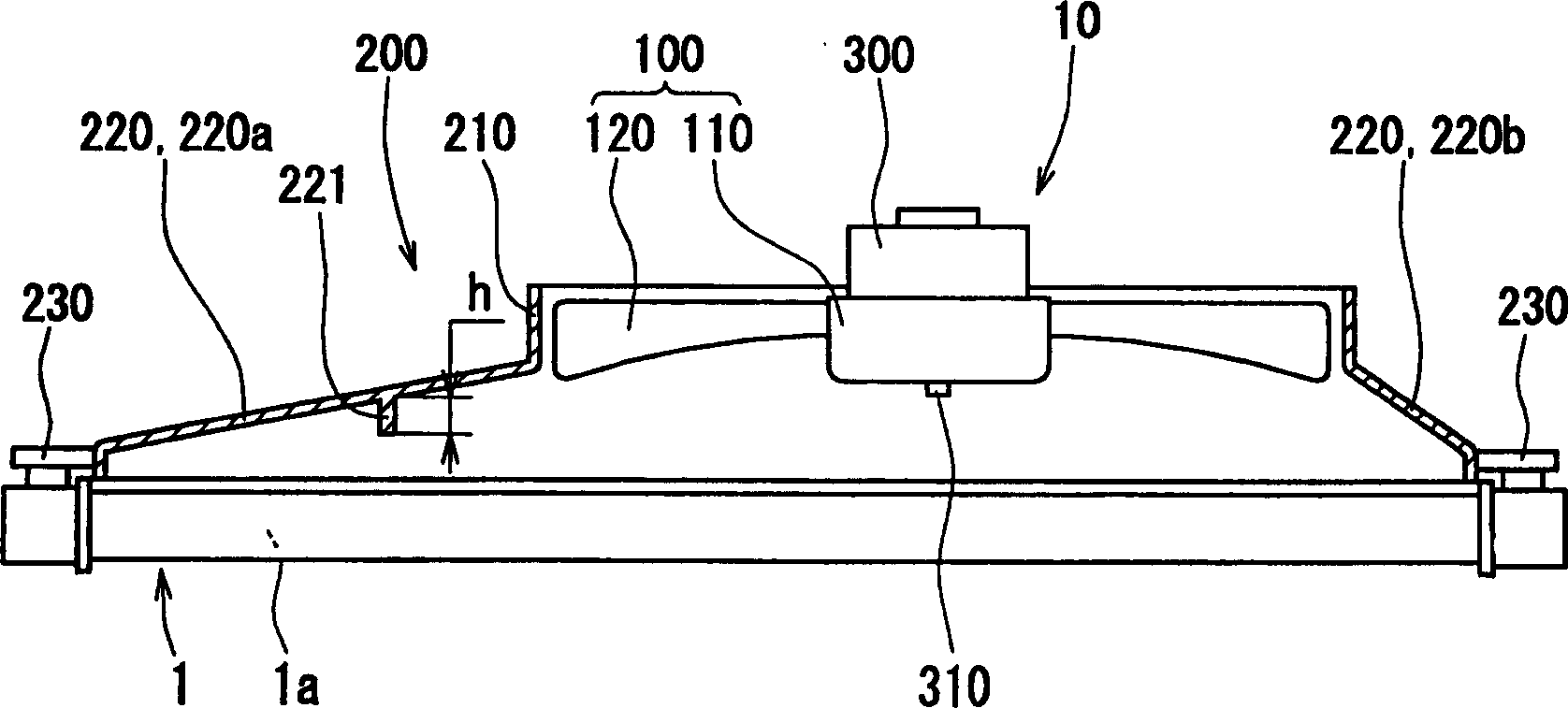

[0020] In this embodiment, the shroud 200 of the present invention is used in the axial blower 10 (electric fan) of the radiator (heat exchanger) 1 . The axial blower 10 is formed by assembling an axial fan 100 and a motor 300 . Figure 1A with 1B The structure of the axial blower 10 is shown.

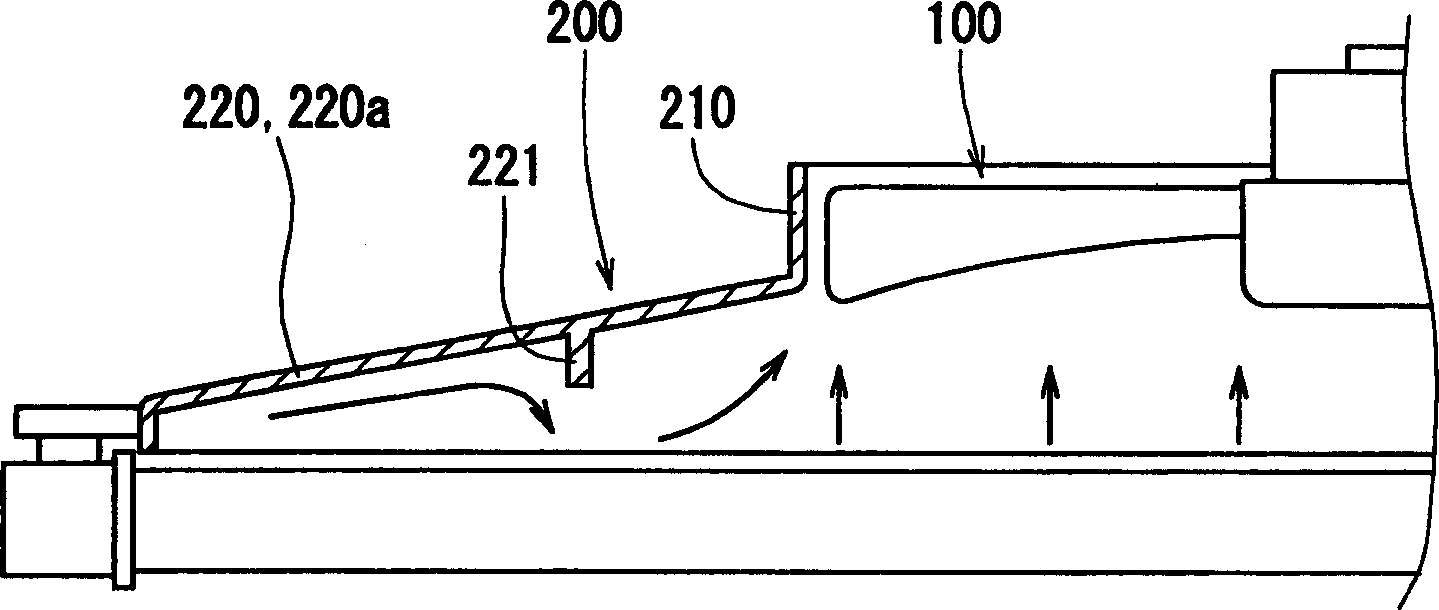

[0021] The axial blower 10 (hereinafter referred to as the blower 10 ) is fixed on the radiator 1 on the engine side of the vehicle through the mounting elements 230 on the four corners of the shroud 200 . The blower 10 sends cool air to the central portion 1a of the radiator 1. As shown in FIG. The blower 10 is an air suction blower 10 that sucks air from the vehicle grill side to the engine side, that is, from the center portion 1 a of the radiator 1 to the axial fan 100 .

[0022] The axial flow fan 100 (hereinafter referred to as the fan) is made of polyp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com