Dry etching device and air pore device fixing on the same

A dry etching and etching technology, which is applied in the direction of electrical components, discharge tubes, plasma, etc., can solve the problems of gas inlet tip discharge, particle pollution, etc., and achieve the effect of reducing particle pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The dry etching device of the present invention can avoid plasma etching near the gas inlet, so that problems such as tip discharge and particle pollution can be effectively reduced. The following will clearly illustrate the spirit of the present invention with diagrams and detailed descriptions. After those skilled in the art understand the preferred embodiments of the present invention, they can be changed and modified by the techniques taught in the present invention without departing from the spirit of the present invention. Spirit and scope.

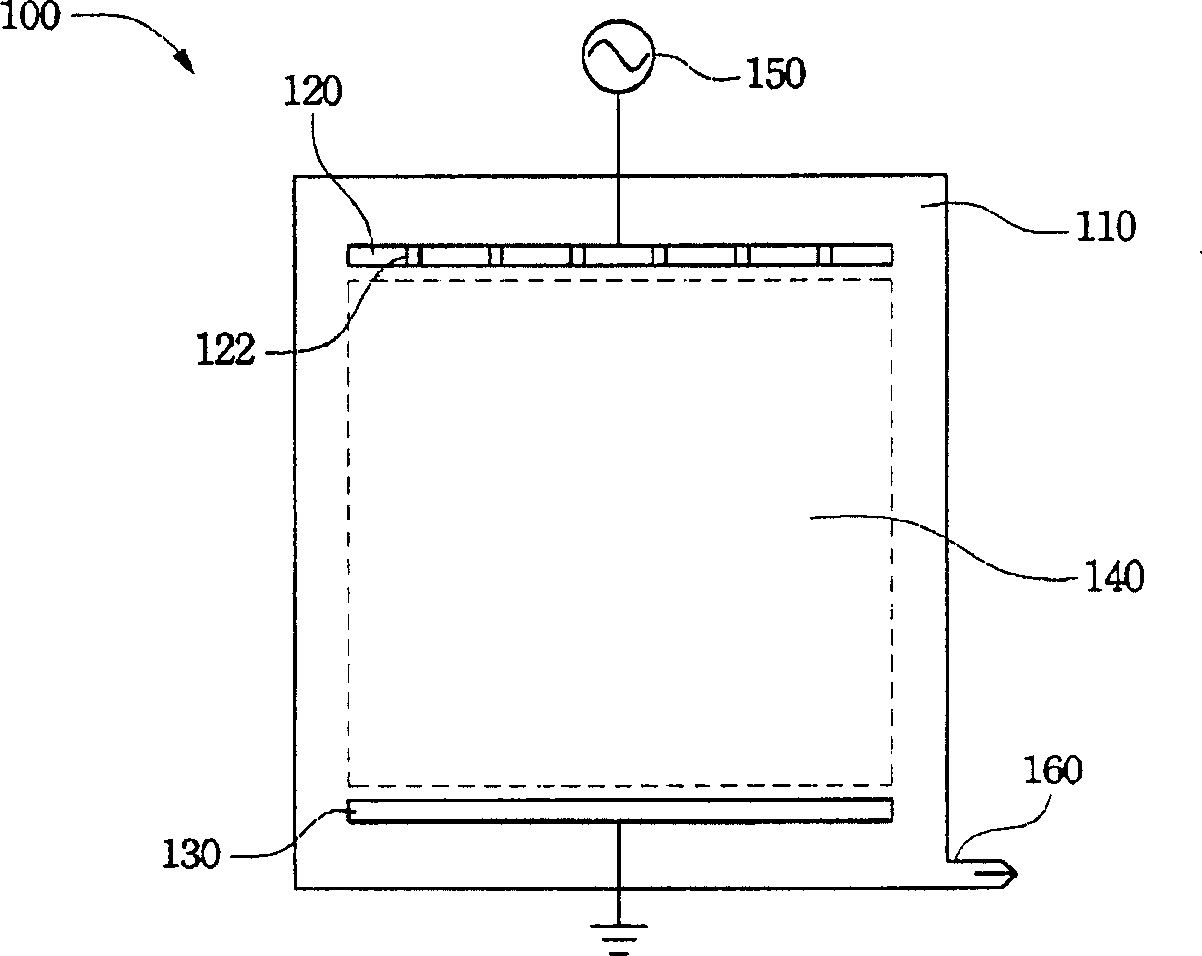

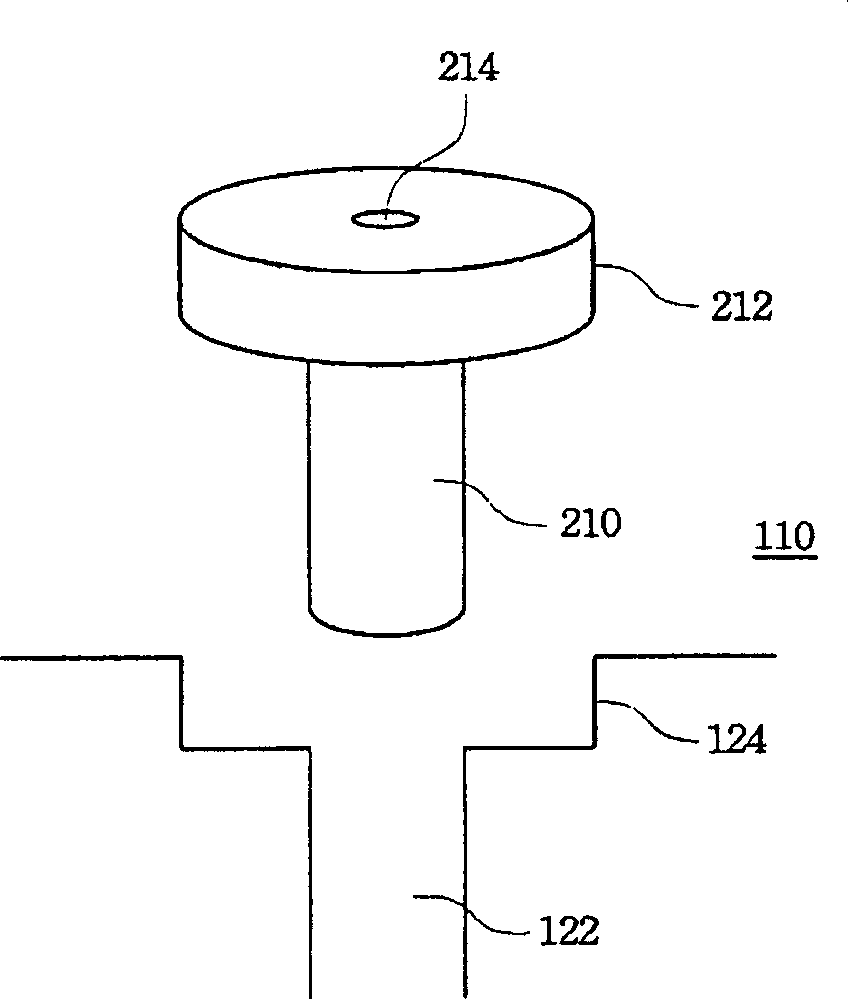

[0024] refer to figure 1 , which is a schematic diagram of a dry etching device according to a preferred embodiment of the present invention. As shown in the figure, the dry etching device 100 is composed of a vacuum chamber 110 , an upper electrode plate 120 , a lower electrode plate 130 , a plasma vacuum discharge area 140 , a power source 150 and a gas outlet 160 . Wherein, the upper electrode plate 120 is installed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com