Honeycomb paperboard cutting mechanism

A technology of honeycomb cardboard and cutting mechanism, which is applied to cardboard items, mechanical processing/deformation, metal processing, etc., can solve the problems of generating a large amount of paper dust, low production efficiency, slow cutting speed, etc., to achieve fast cutting speed and improve production. Efficiency, longevity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

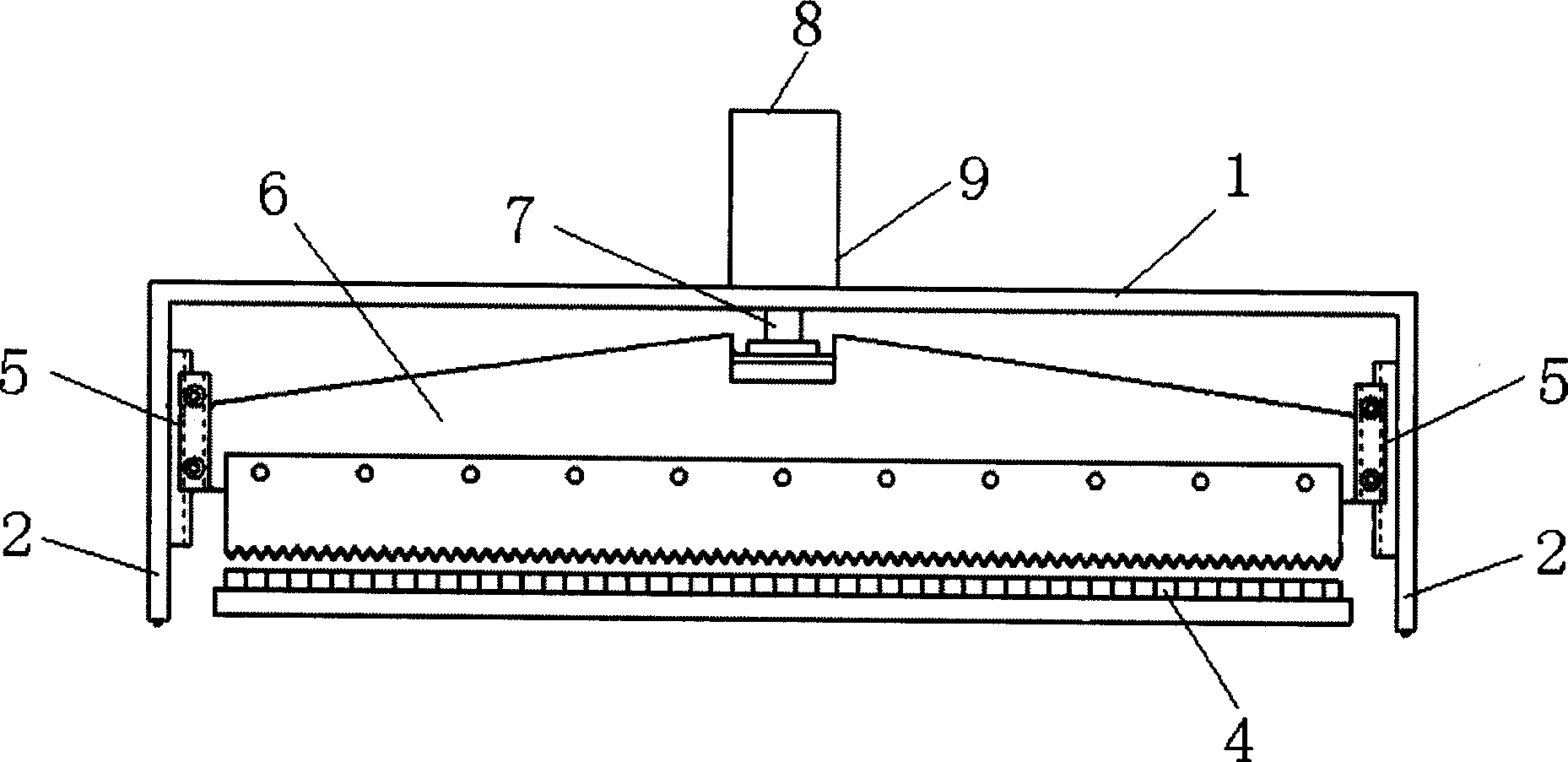

[0013] refer to figure 1 , Honeycomb cardboard cutting mechanism, including portal mounts and knives.

[0014] The portal mounting frame is composed of a beam 1 and two columns 2, honeycomb cardboard 3 passes between the two columns 2 of the portal mounting frame, and longitudinal guide rails 4 are respectively arranged on the two columns 2 of the portal mounting frame.

[0015] Described cutter is made up of cutting knife 5 and mounting plate 6, and described cutting knife 5 is installed on described mounting plate 6, and cutter is installed on the described portal mounting frame by driving mechanism 9, and described cutter edge The width is adapted to the width of the honeycomb paperboard 3 and faces the plane where the honeycomb paperboard is located. The driving mechanism is as follows: it includes a connecting rod 7 connected to the mounting plate at one end and a spring sleeved on the connecting rod, and the connecting rod 7 passes through the crossbeam 1 of the gantry ...

Embodiment 2

[0019] refer to figure 1 , the drive mechanism 9 is an electromagnetic drive mechanism, the electromagnetic drive mechanism is electrically connected to a controller, the running path of the honeycomb paperboard 3 is equipped with a sensor for sensing the running length of the honeycomb board, the sensor and The controller is electrically connected.

[0020] During the working process, the honeycomb cardboard 3 passes through the door of the door-type installation frame, and at the same time, the controller calculates the length of the honeycomb cardboard 3 passing through the door-type installation frame. When the required length is reached, the electromagnetic drive mechanism is immediately controlled. The mechanism drives the cutter to move down along the longitudinal guide rail 4 until the honeycomb paperboard is cut off, and finally the electromagnetic drive mechanism drives the cutter to return to the initial position along the longitudinal guide rail 4, so far, a piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com