Engine pendant

A suspension device and engine technology, applied in transportation and packaging, special foundation layout, supporting machines, etc., can solve problems such as poor stability, damage, and fracture of the swing engine 2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

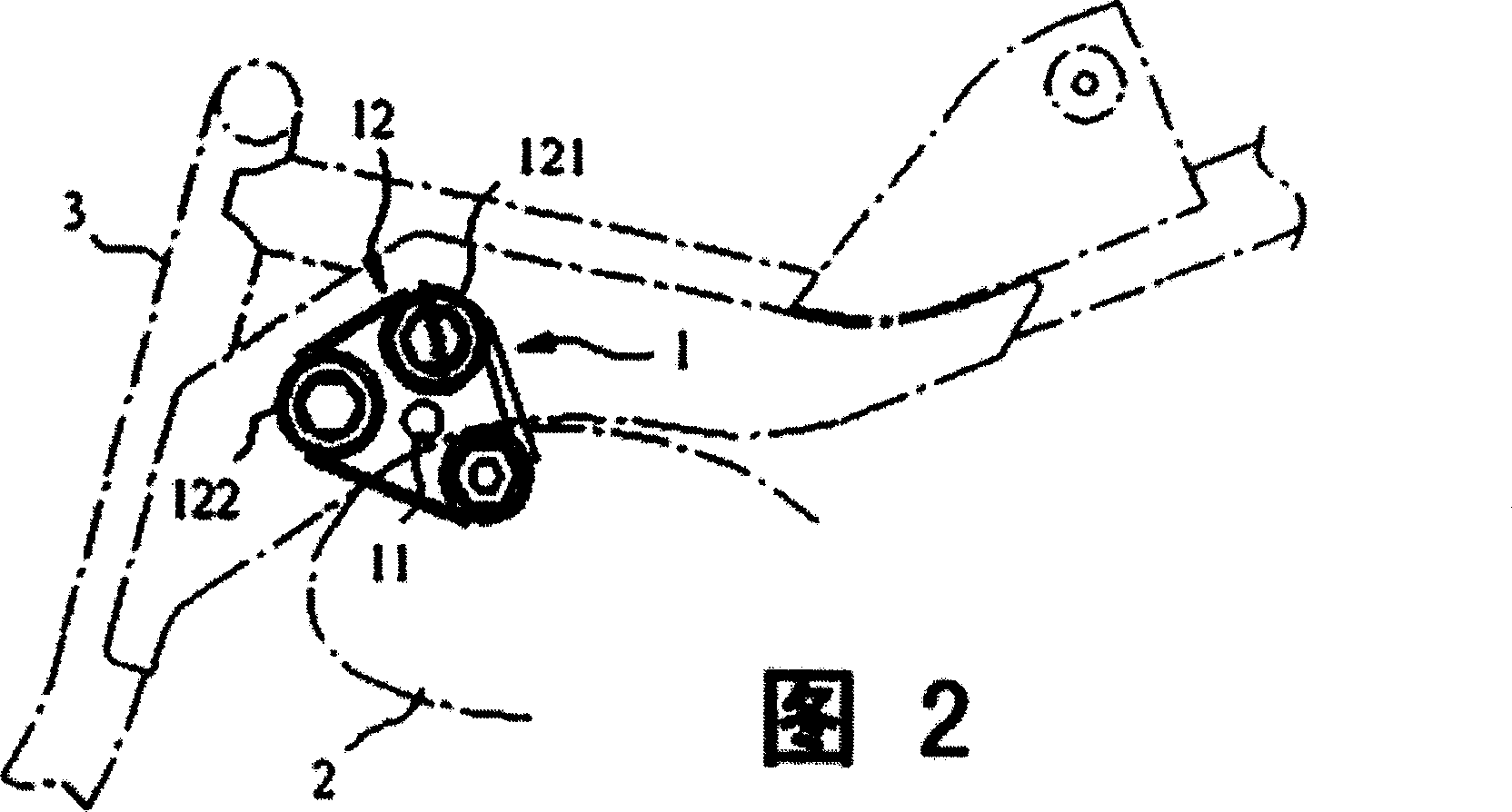

[0017] The aforementioned and other technical contents, features and effects of the present invention will be clearly understood in the following detailed description of a preferred embodiment with reference to the drawings.

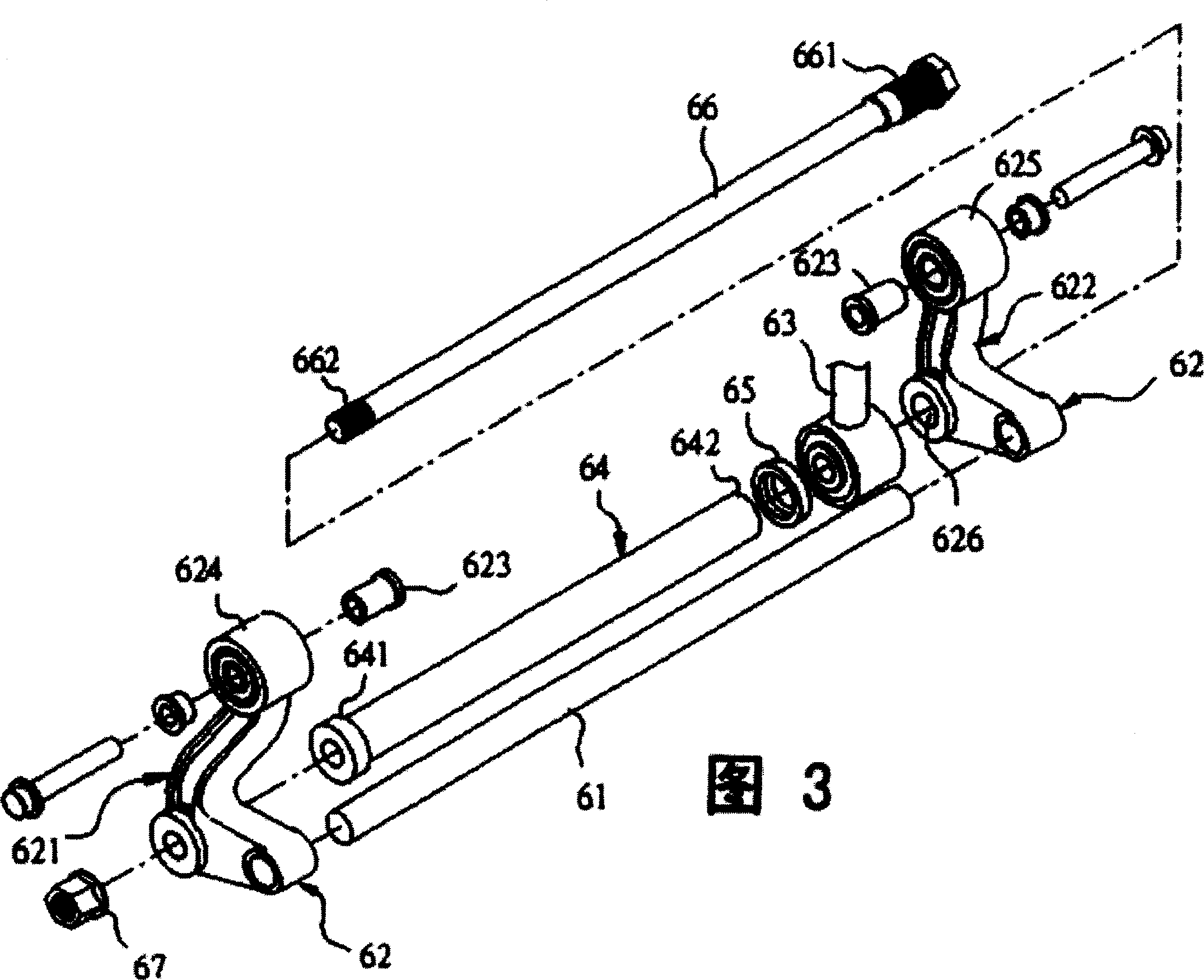

[0018] refer to Figure 4 and Figure 5 , is the preferred embodiment of the engine suspension device 6 of the present invention, which is used to suspend and assemble a swing engine 4 of a motorcycle on the vehicle frame 5 of the motorcycle. The swing engine 4 has two lug bearings 41 spaced apart.

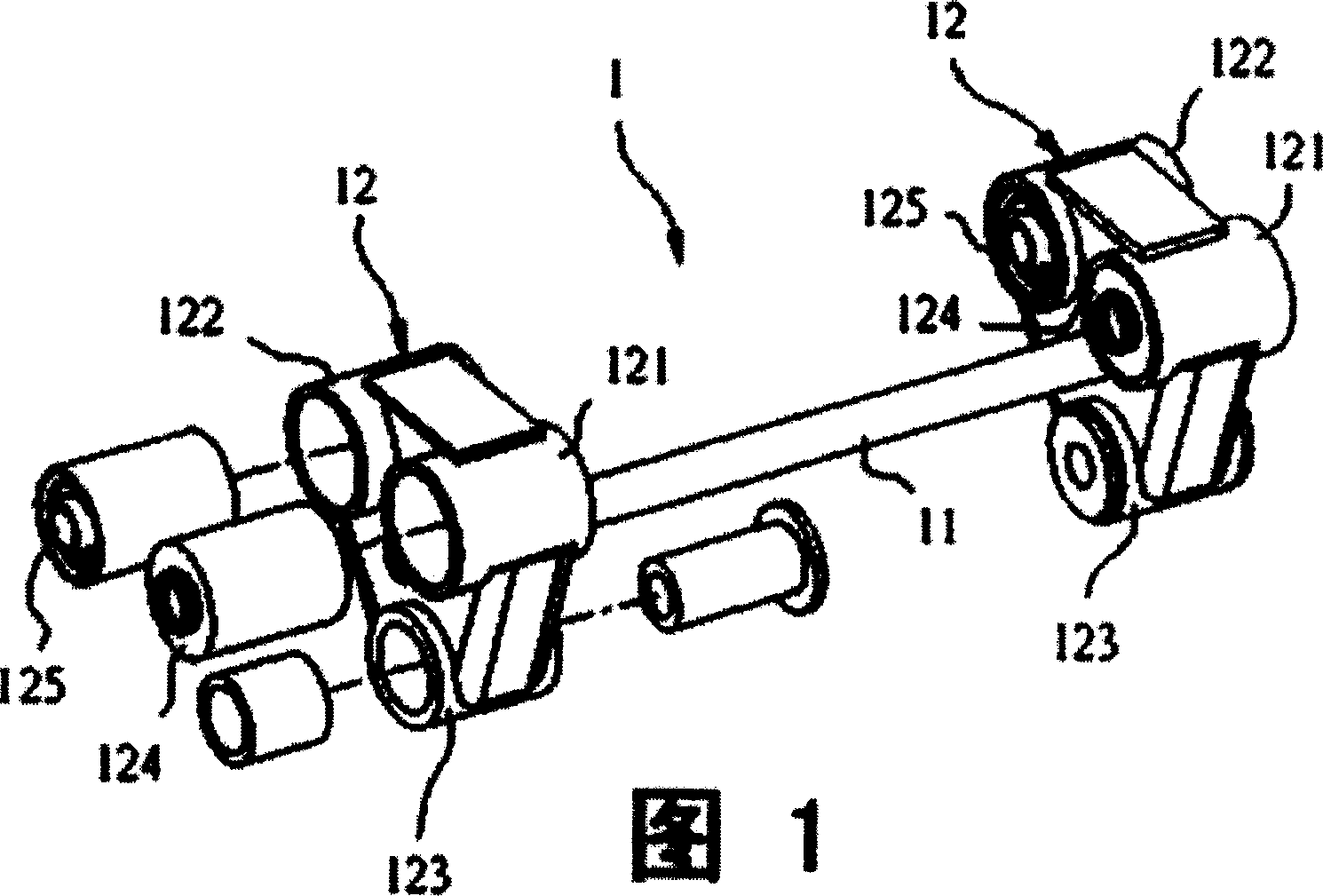

[0019] See Figure 3 with Figure 4 The engine suspension device 6 includes a connecting rod 61 located above the two lug bearings 41 and having a length greater than the distance between the two lug bearings 41, a frame locking unit 62, a tie rod seat 63, and a The positioning sleeve 64 in the two lug bearings 41 , a positioning sleeve cover 65 , a fixed shaft 66 , and a lock attachment 67 .

[0020] The frame locking unit 62 has a first locking seat 621 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com