Riving knife assembly for table saws

A technology of components and riving knives, which is applied in the direction of sawing components, circular saws, sawing machine devices, etc., and can solve the problem of difficult disassembly of riving knife components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

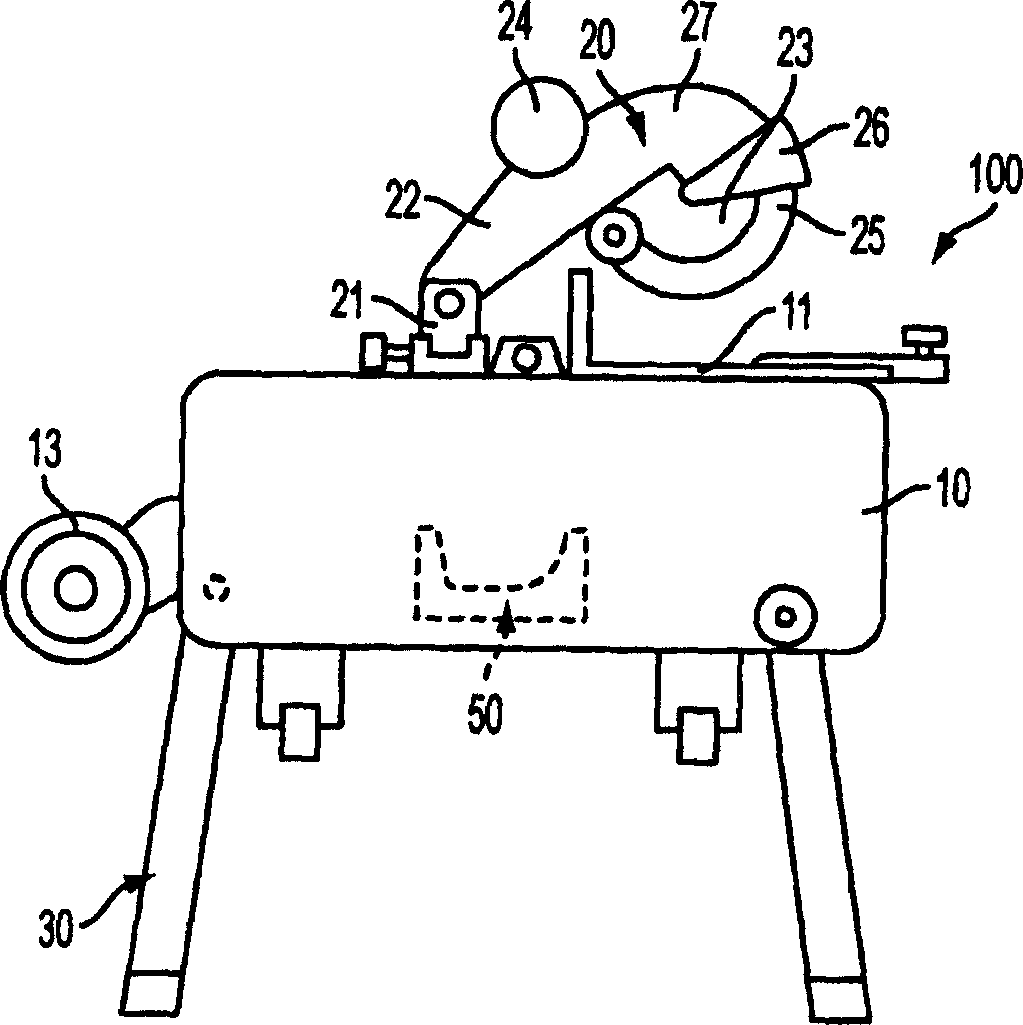

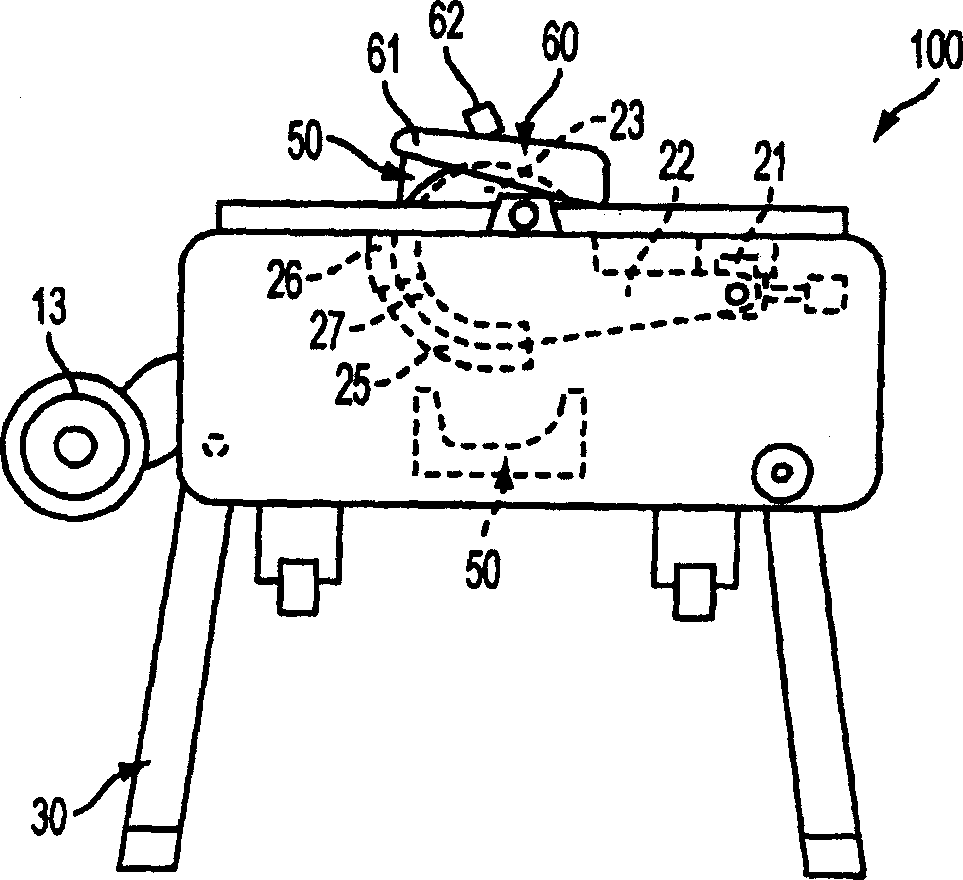

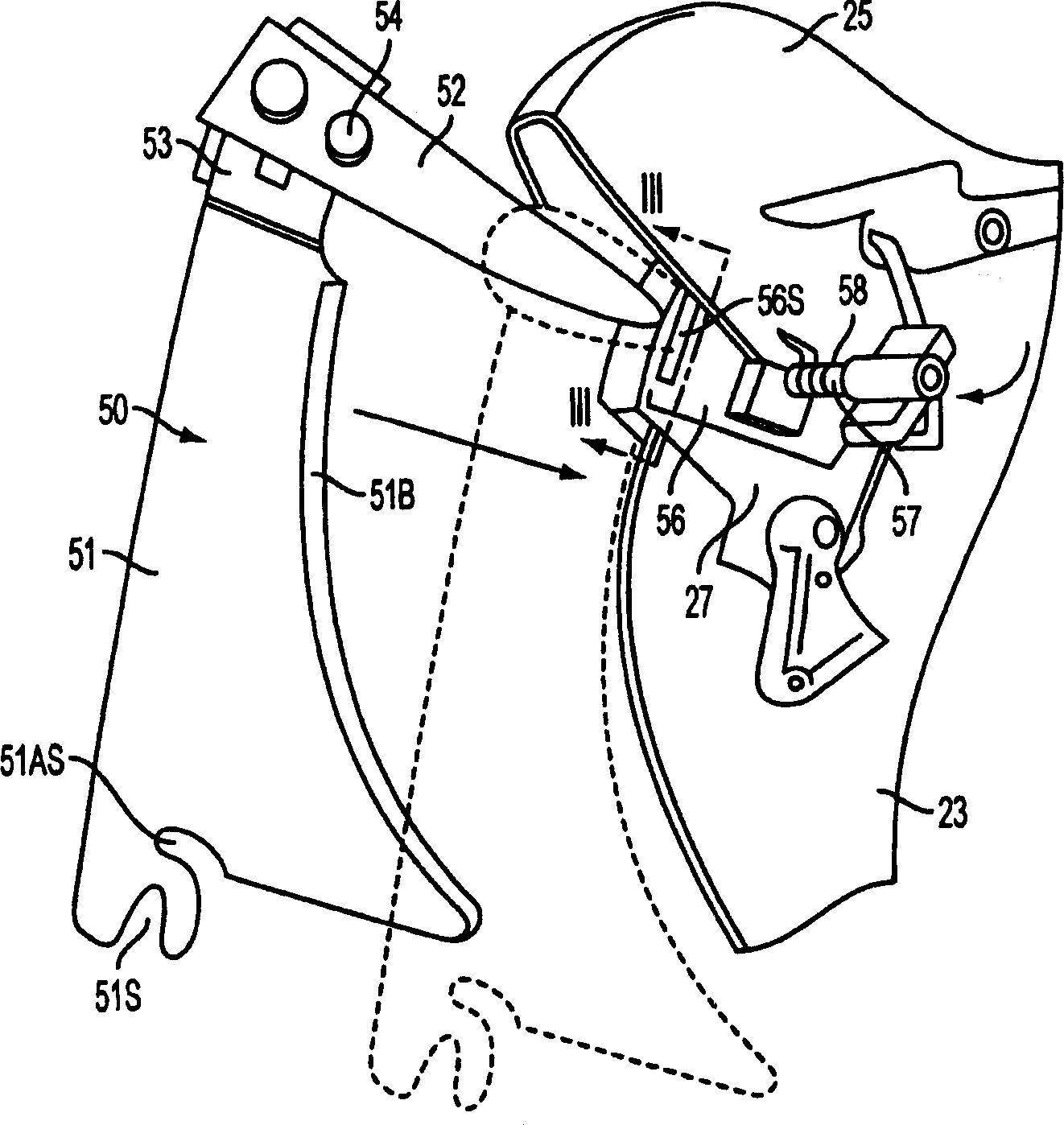

[0012] The invention will now be described with reference to the drawings, wherein like reference numerals refer to like parts. Referring to FIG. 1 , a table / miter saw combination saw 100 may include a base assembly 10 , a table 11 supported by the base assembly 10 , and a saw assembly 20 supported by the table 11 . The saw assembly 20 may include a trunnion 21 disposed on the table 11 , a pivot arm 22 pivotally connected to the trunnion 21 , a motor 24 supported by the arm 22 and driving a saw blade 23 . The arm 22 also supports an upper blade guard 27 which covers the upper portion of the blade 23 . The lower blade guard 25 is pivotally connected to the upper blade guard 27 . An auxiliary blade guard 26 is pivotally connected to the lower blade guard 25 .

[0013] Workbench 11 is preferably pivotally connected to base assembly 10 via connection 15 so that when workbench 11 is in Figure 1A When in the direction of the table 11, the saw assembly 20 can be used as a miter s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap