Assembling connecting lock of display rack

An exhibition rack and connection lock technology, applied in the field of connection locks, can solve the problems of not being very effective in preventing collapse and eccentricity, reducing the strength of the lock shell, and low reliability, and achieving the effects of reducing the number of core pulling, simplifying the mold, and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

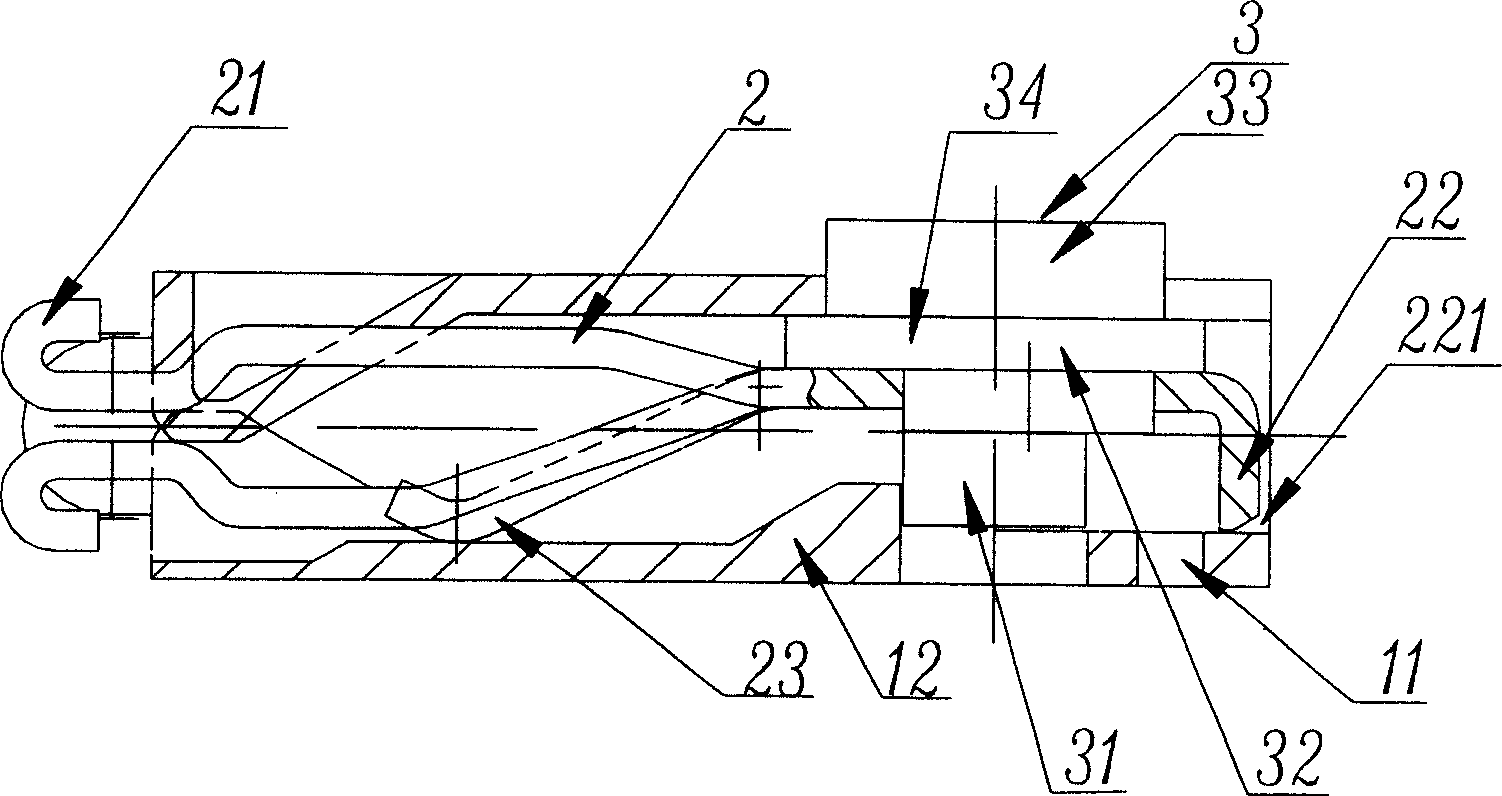

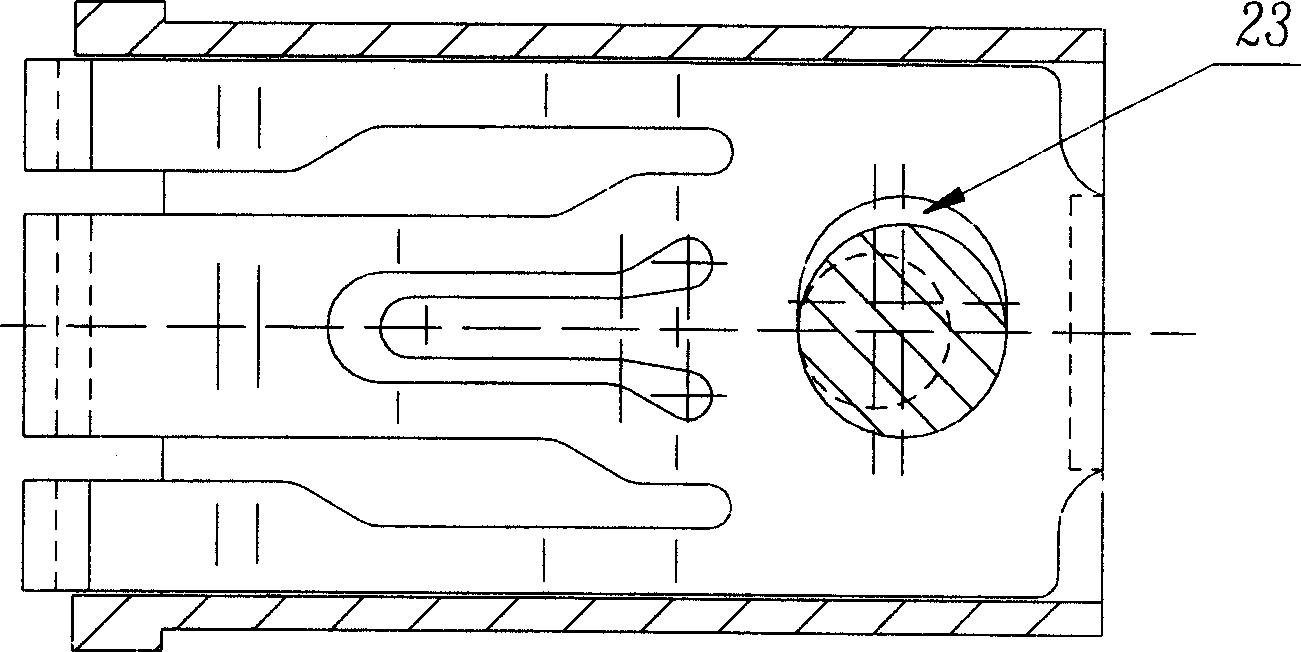

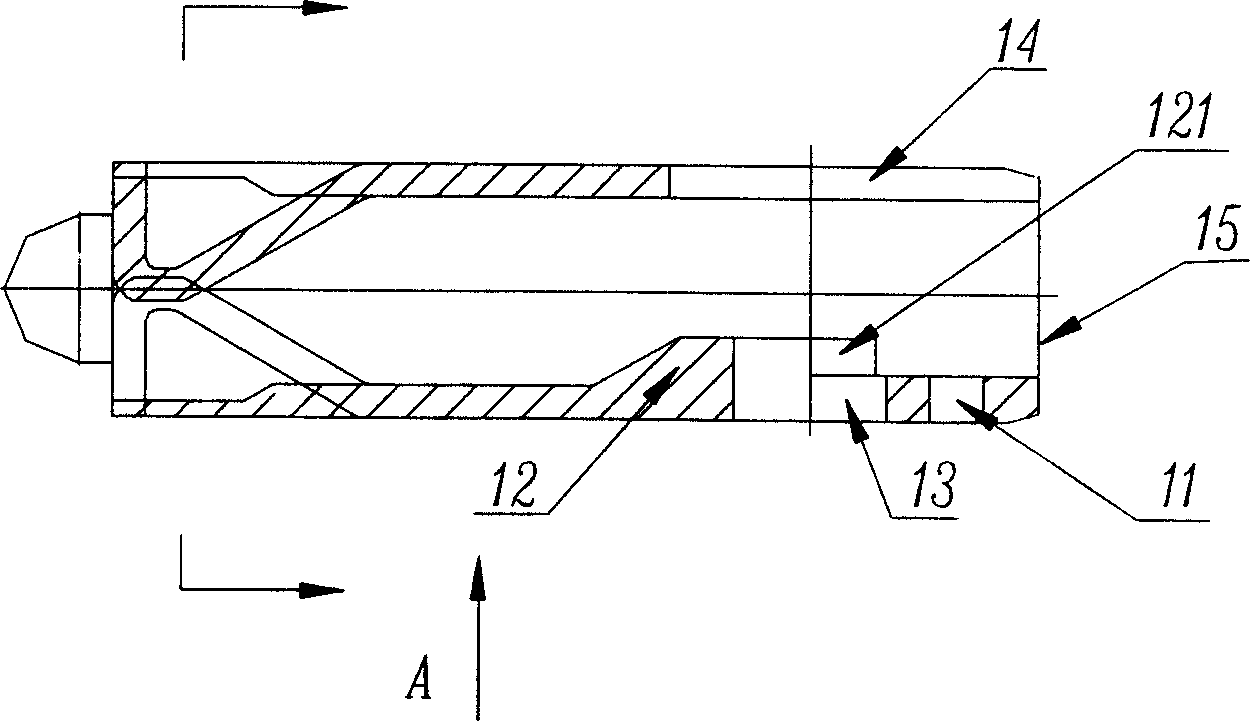

[0017] An exhibition rack assembly connection lock for connecting the parts of the exhibition equipment together, which is composed of a lock case 1, a lock plate 2 and an eccentric wheel 3, the eccentric wheel 3 is composed of a wheel shaft 31, an eccentric disc 32 and a wheel cap 33, and the eccentric Disc 32 is located on the wheel shaft 31, wheel cap 33 is located on the eccentric disc 32, lock plate 2 is located in the lock housing 1, at least two hook claws 21 are provided at the head of lock plate 2, behind the lock plate 2 There is an eccentric disk matching hole 23 for use in conjunction with the above-mentioned eccentric disk 32 at the top. The lock housing 1 is a closed shell with a cavity inside. A claw window 16 is provided at the front end of the closed shell. The claw 21 automatically The inside of the closed housing protrudes from the closed housing through the claw window 16, and the rear portion of the closed housing is provided with an axle hole 13 that is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com