Fume exhaustor for kitchen

A technology for range hoods and kitchens, applied in the direction of oil fume removal, application, and household stoves, etc., which can solve problems such as rising costs, increasing thickness, and increasing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below with reference to accompanying drawing:

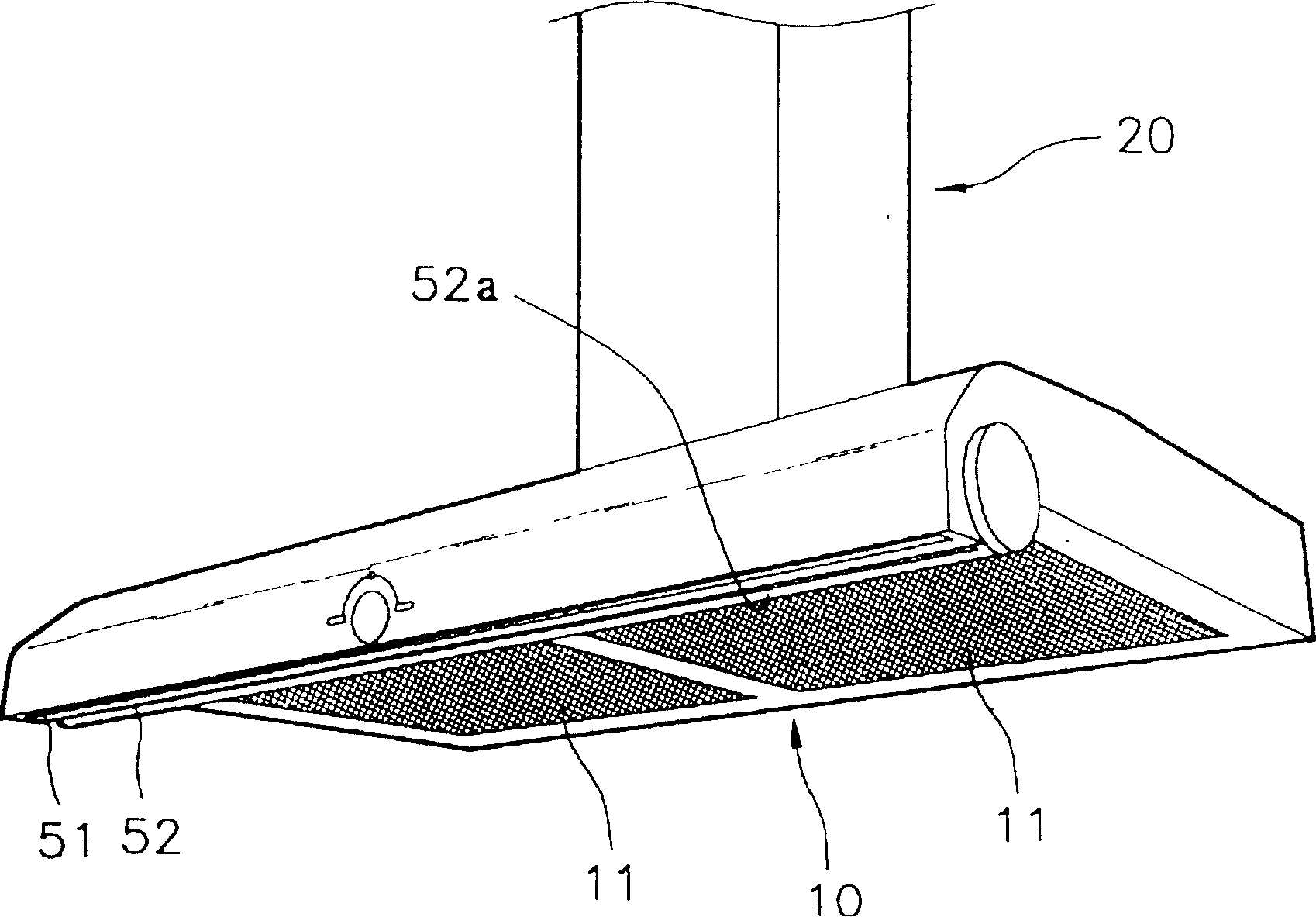

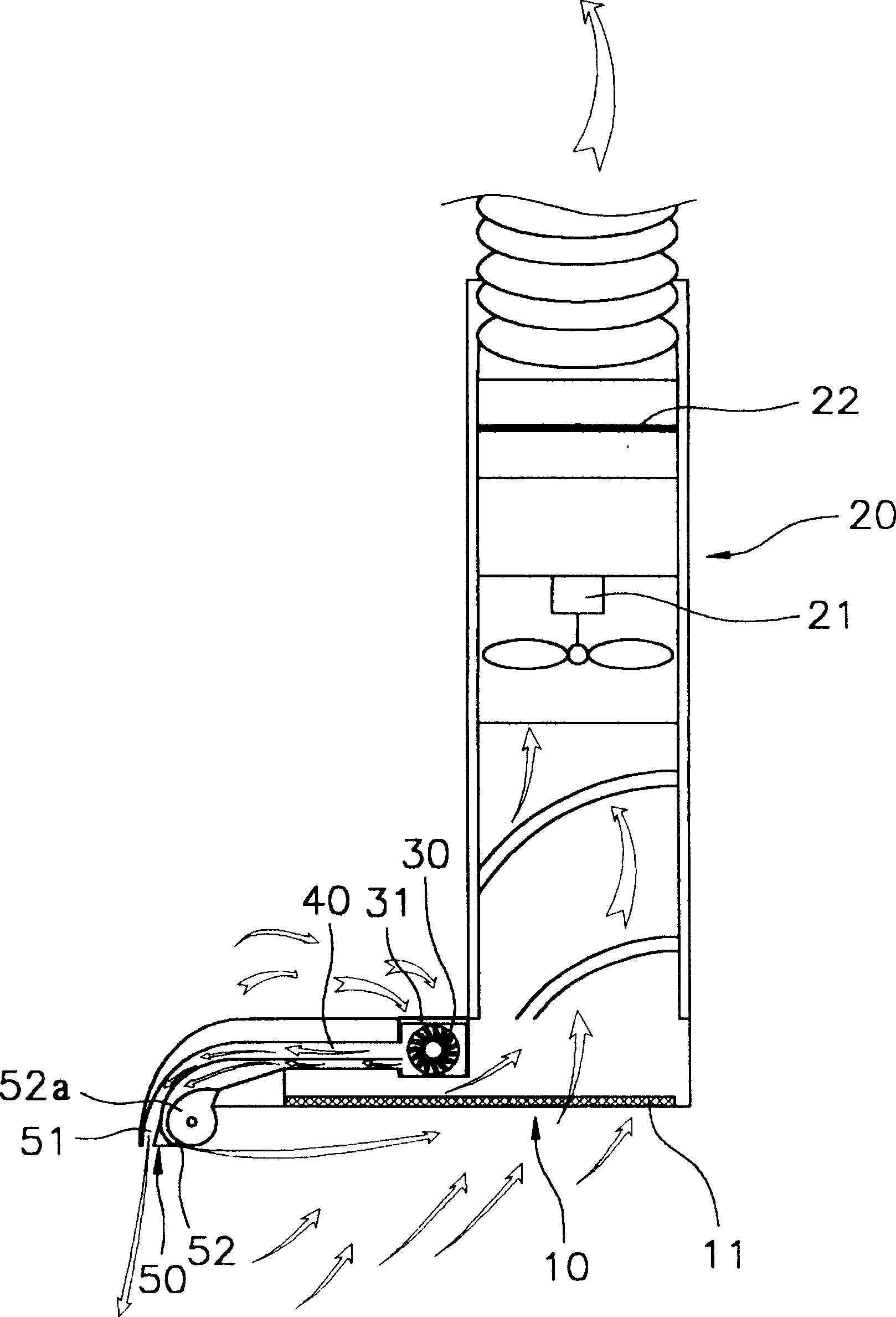

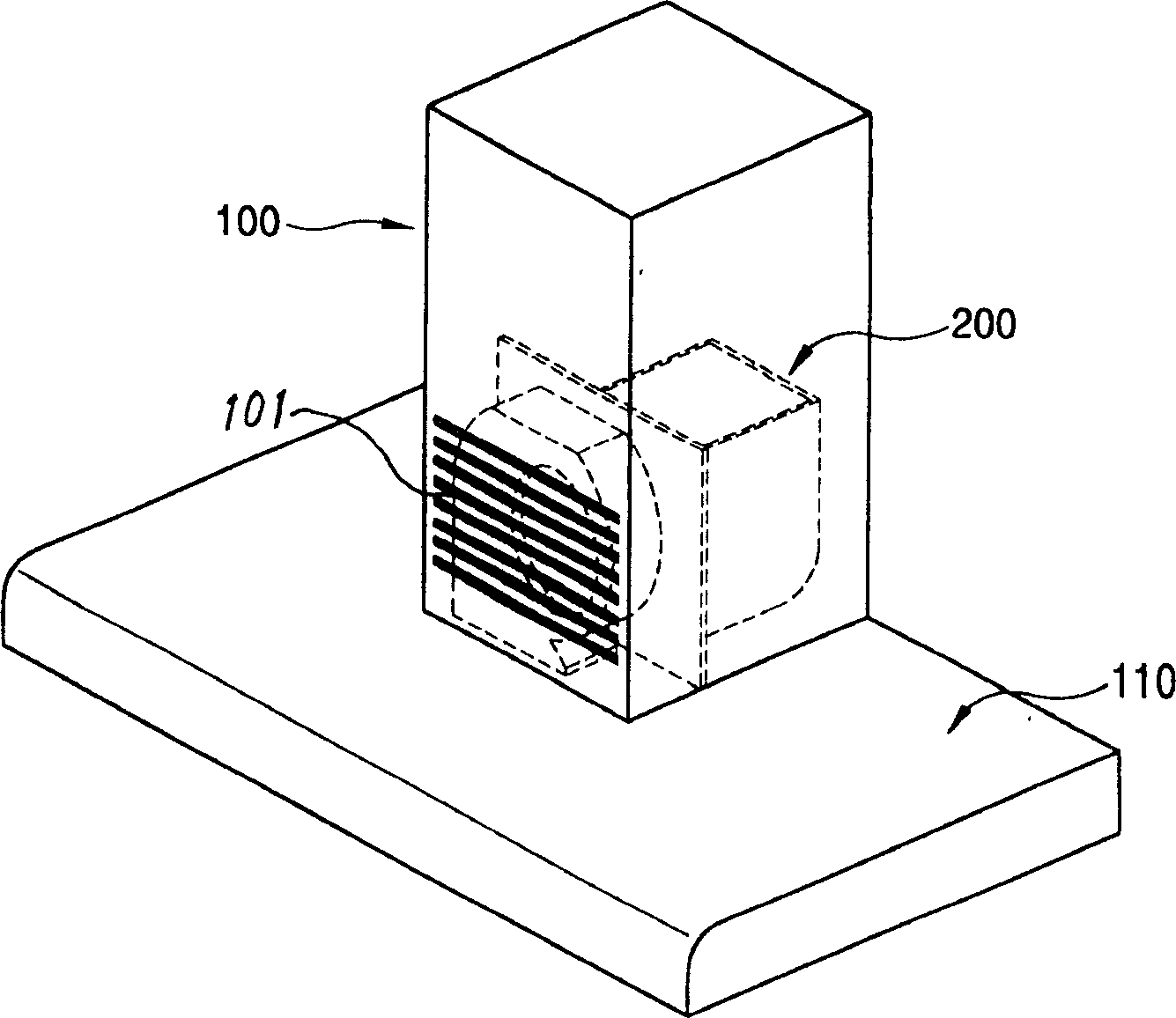

[0019] like image 3 , 4 , 5, the present invention includes, the vertical exhaust pipe 100 that is arranged on the ceiling to discharge the indoor air upwards, and the horizontal exhaust pipe 110 that is formed in the bottom of the vertical exhaust pipe 100 and is connected as a whole, is arranged on The interior of the vertical exhaust duct 100, the exhaust fan 210 that sucks in indoor air and discharges it upward, sucks the indoor air from the inflow port 101 formed in the middle of the vertical exhaust duct 100, and sends the sucked indoor air from the horizontal exhaust duct in order to prevent the diffusion of pollutants. The return fan 220 discharged under 110; the discharge fan 210 and the return fan 220 driven by the same motor in the same fan casing 201 together form the oil suction fan 200; it is arranged inside the horizontal exhaust duct 110 and distinguishes the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com