Non-blocking primary air speed measuring device

A wind speed measurement, non-clogging technology, applied in measurement devices, fluid velocity measurement, velocity/acceleration/impact measurement, etc., can solve problems such as the inability to fundamentally eliminate clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

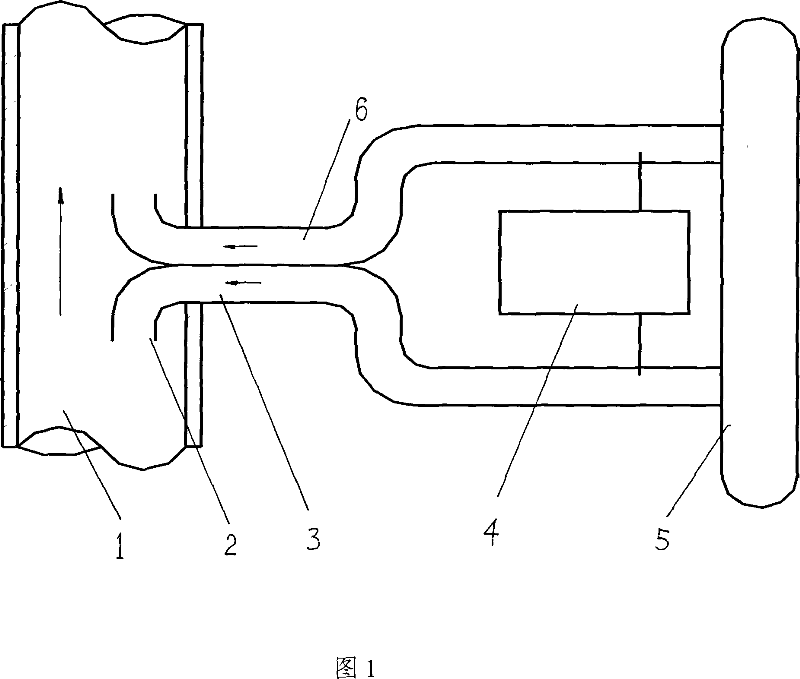

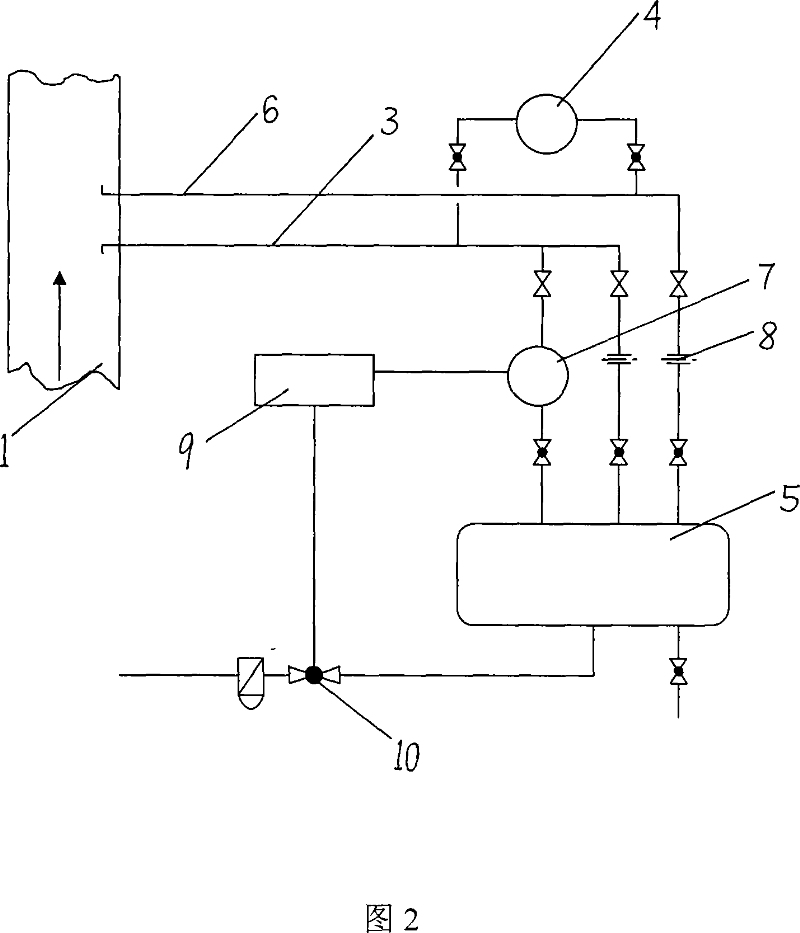

[0021] As shown in Figure 1, the non-blocking primary wind speed measuring device, the air flow containing pulverized coal flows in the primary air duct 1 of the power plant, the full pressure pressure pipe 2 and the static pressure pressure pipe 6 are installed on the primary air pipe of the power plant, A differential pressure transmitter 4 is installed between the pressure tube and the static pressure tube. The range of the differential pressure transmitter is 0-1.6KPa, the power supply is 24VDC, and the output is 4-24mA. The pressure-taking pipe is connected to the same pressure-receiving gas tank, and a control valve and a throttle valve 8 are installed on the pipeline. The pressure-stabilizing gas tank provides constant-velocity weak airflow along the full-pressure pressure-taking pipe and the static pressure-taking pipe to the pressure-taking port 2 , the pressure-stabilizing air tank 5 is connected to the instrument wind compressed air source, and the air is stored in t...

Embodiment 2

[0024] As shown in Figure 1, the non-blocking primary wind speed measuring device, the primary air pipe 1 of the direct blowing system of the newly built power plant has a mixed air flow of air and pulverized coal, and the full pressure pressure pipe 3 and the static pressure pressure pipe 6 are installed in the primary wind pipe of the power plant. On the tube, a differential pressure transmitter 4 is installed between the full pressure pressure tube and the static pressure tube. The range of the differential pressure transmitter is 0-1.6KPa, the power supply is 24VDC, the output is 4-24mA, The pressure-taking pipe and the static pressure-taking pipe are connected to the same regulated gas tank 5, and the constant-velocity weak airflow provided by the regulated gas tank flows along the full-pressure pressure-taking pipe and the static pressure-taking pipe to the pressure-taking port 2, and the differential pressure becomes The dynamic pressure value collected by the transmitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com