Mass sensor based on elastic mass system and method for measuring mass thereof

A quality sensor and quality system technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of cumbersome process, lack of timely data validity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

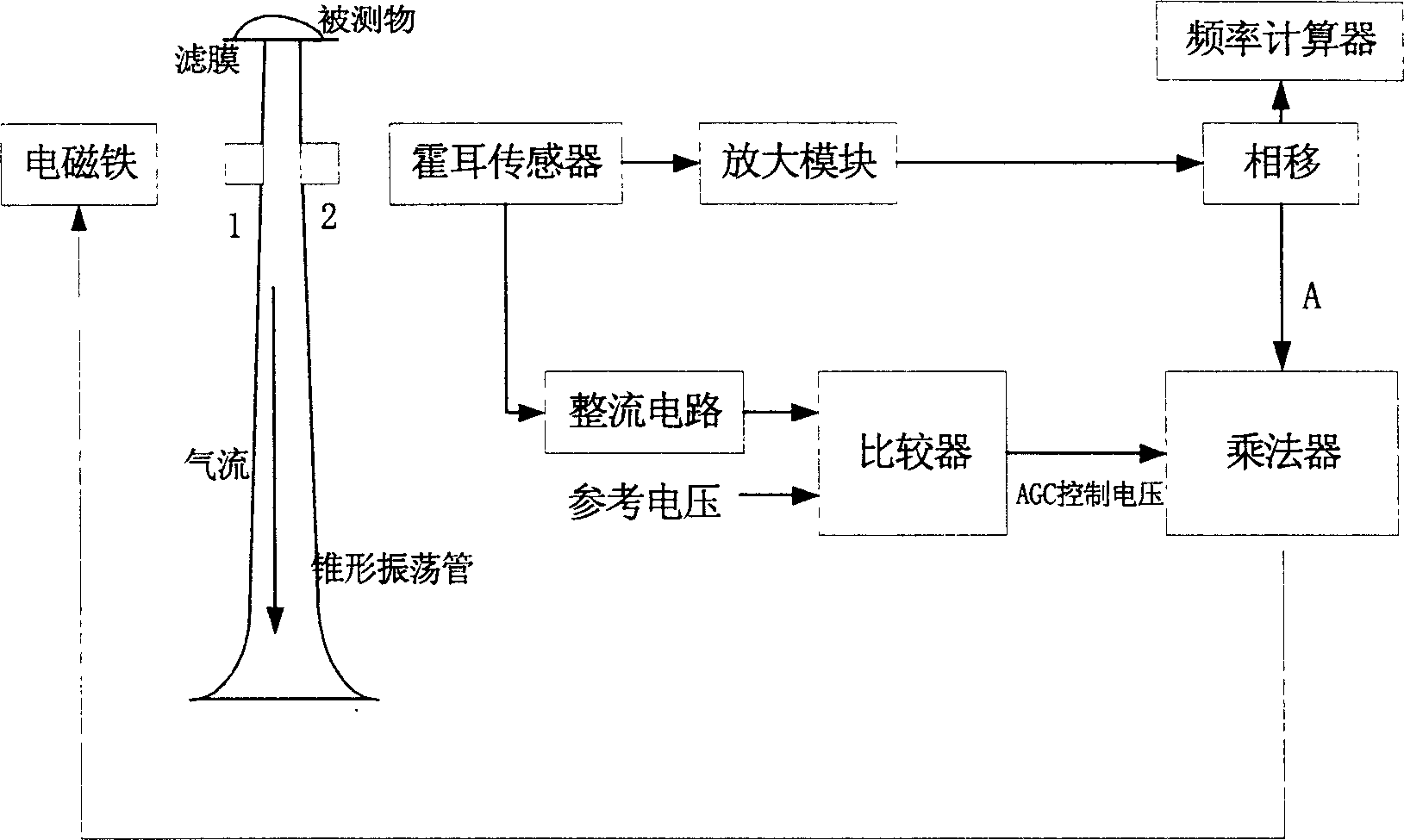

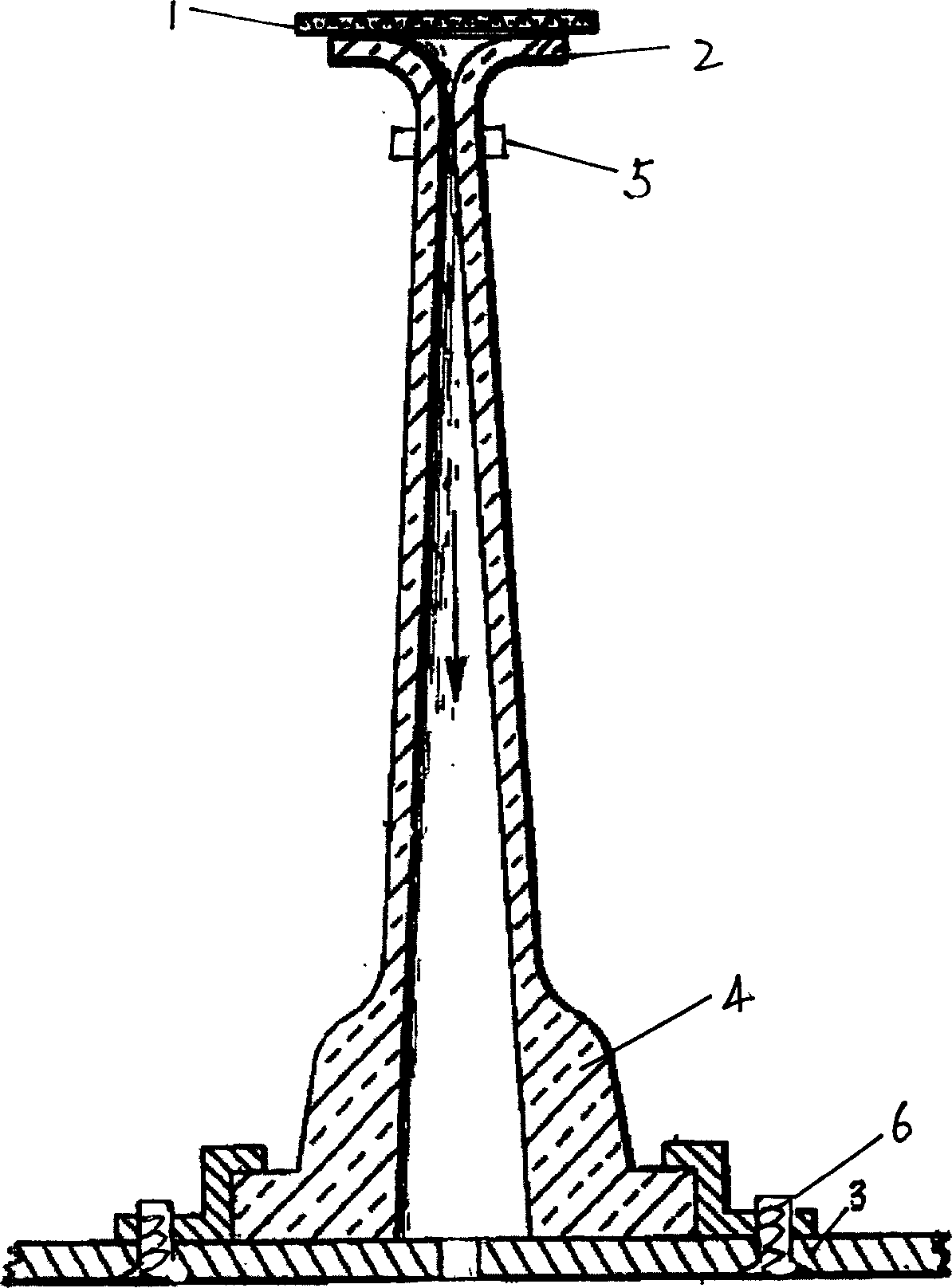

[0026] see figure 1 , figure 2 .

[0027] The oscillating tube of the present invention is a hollow conical tube, its cone bottom 4 is fixed on the frame 3, a filter membrane 1 is fixed on the cone tip 2, and two magnets are installed on both sides of the neck of the conical tube at 1 cm from the top. Steel 5. The hollow tapered tube is a hollow thin-walled tube made of quartz, glass, and ceramics. A platform collar is arranged on the frame 3, which is pressed on the edge of the bottom end of the tapered pipe, and a spring 6 is installed between the platform collar and the frame. Can act as a buffer.

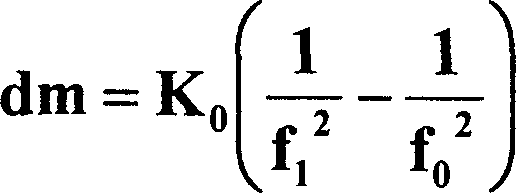

[0028] The method of measuring the quality of tiny particles suspended in the gas by using the oscillating tube is: install an electromagnet and a linear Hall device at about 1 cm on both sides of the magnetic steel; The natural frequency oscillates, and the linear Hall device senses the change signal of the magnetic field strength at the same frequency as the hollow conic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com