Shaping machine for filament, strip and flake pickles

A forming machine and strip technology, which is applied in the field of sheet pickle forming machines, strips, and filaments, can solve the problems of high labor intensity, low production efficiency, and unsafety, and achieve the effect of low labor intensity and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

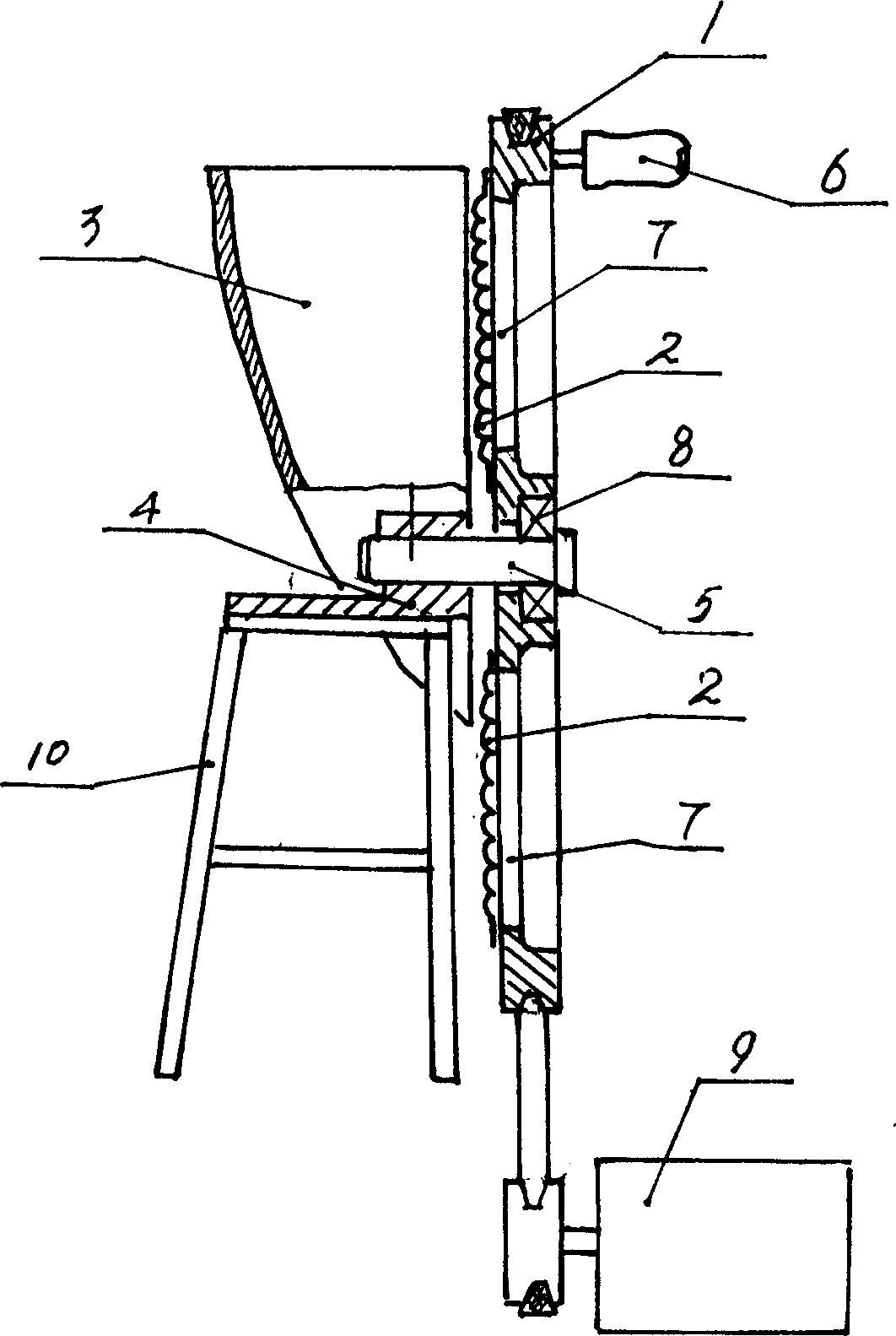

[0009] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

[0010] as attached figure 1 As shown, the filamentous, strip-like and sheet-like pickle processing equipment of the present invention is composed of a motor 9, a rotating disc 1, a forming blade 2, a feed hopper 3, a base 4, a main shaft 5 and a frame 10, and the feeding The bucket 3 is arranged on the base 4 and is connected with the base 4 as a whole. The base 9 is fixed on the frame 10, and four discharge slots 7 are opened in equal parts on the rotating disk 1, and the forming blade 2 is covered in the discharge trough. On the mouth 7, the cutting edge of the forming blade 2 faces the object to be processed. The forming blade 2 is fixed on the rotating disk 1 and is located on the same side of the feeding hopper 3. The rotating disk 1 is supported on the base 4 through the bearing 8 and the main shaft 5. , The motor 9 is connected to the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com