Large volume heat inputing in the welding tie-in tenacity excellent thick steel plate

A technology for welding joints and thick steel plates, applied in the field of thick steel plates, to achieve the effect of excellent toughness of welded joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

PROBLEM TO BE SOLVED: To provide a high strength thick steel plate in a class of 590 to 780 MPa which has excellent welded joint toughness (HAZ toughness) even when subjected to high heat input welding.

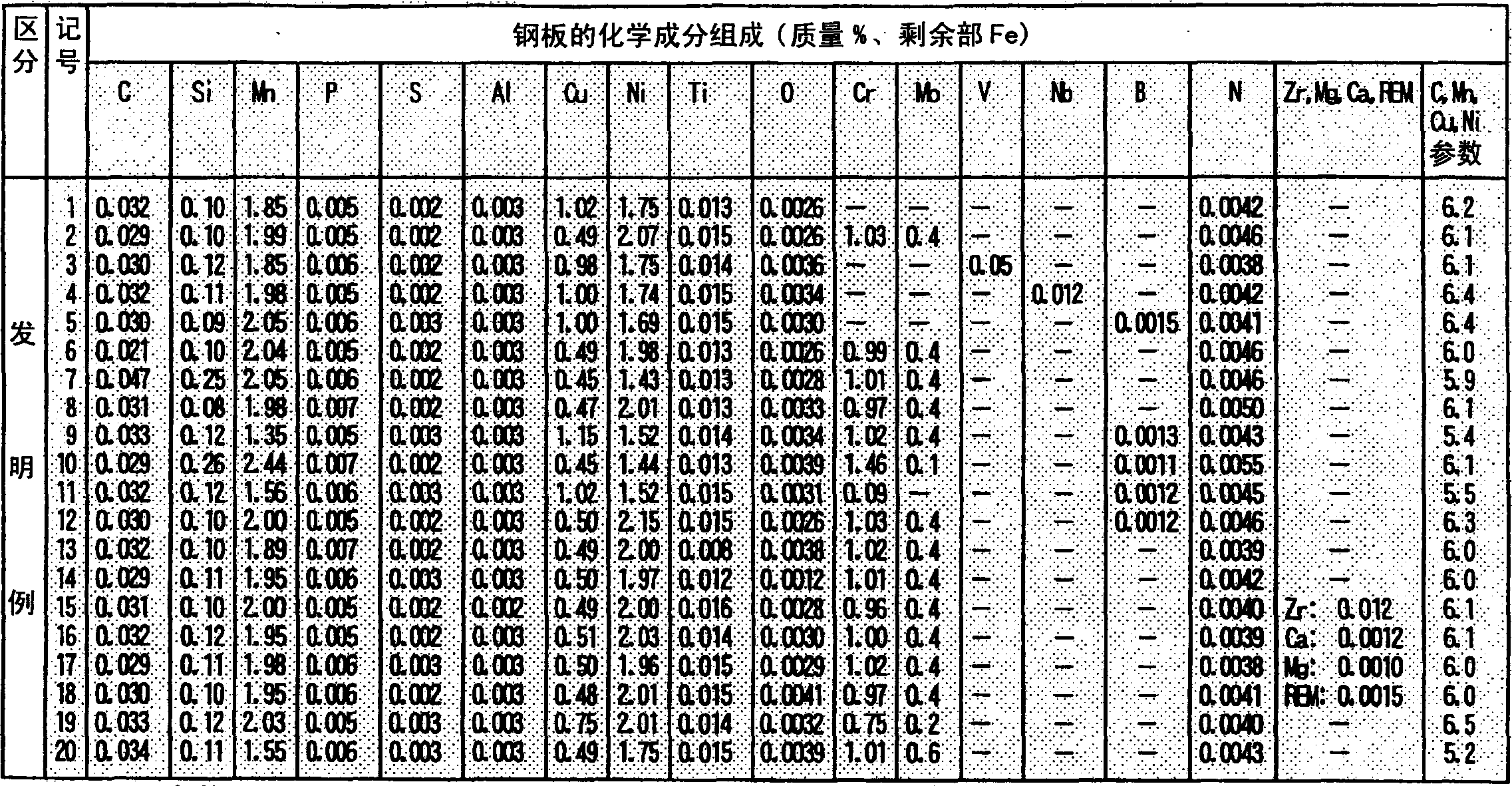

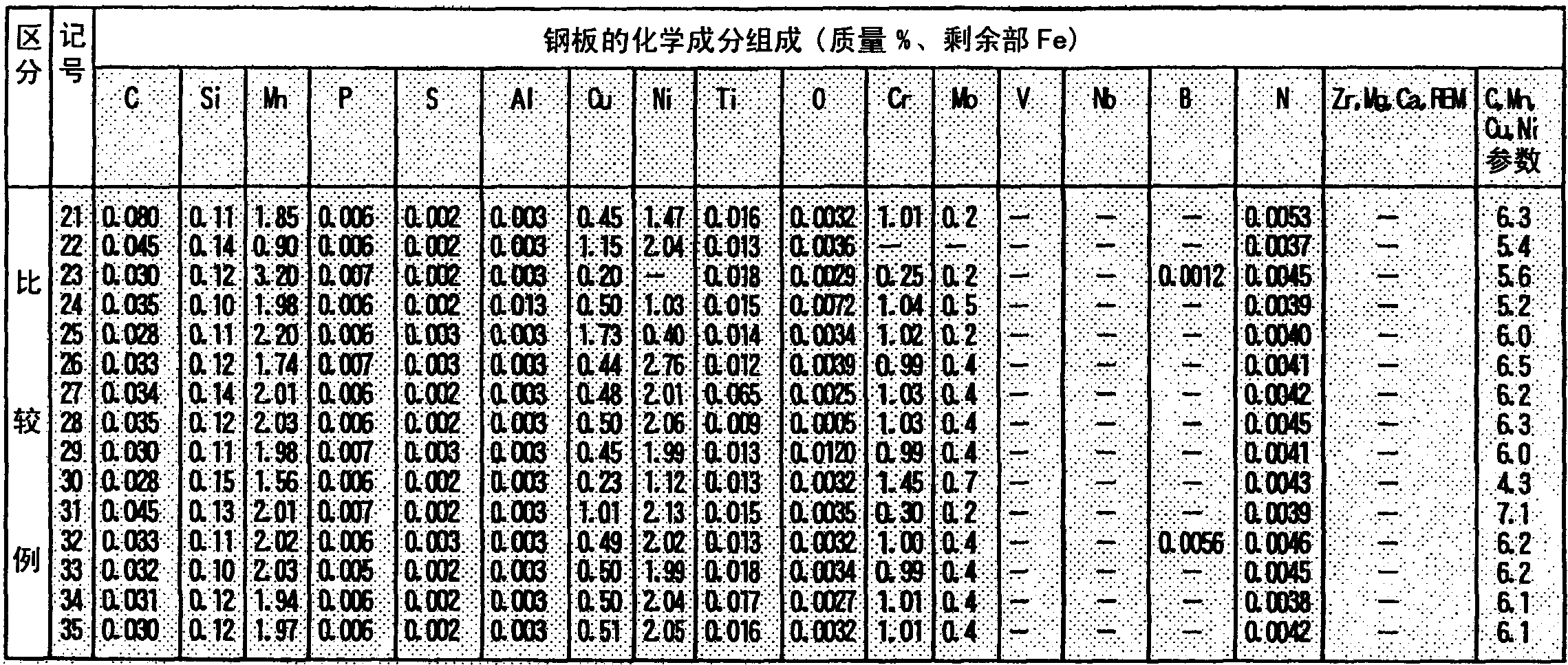

SOLUTION: Specified components of a thick steel plate, in particular, the total content of C, Mn, Cu and Ni are controlled by a specified parameter, the average number of fine Ti-containing oxides with a mean particle diameter of 0.05 to 1 μm is controlled to ≥10,000 pieces/cm<SP>2</SP>, and also the average number of coarse Ti-containing oxides with a mean particle diameter of ≥2 μm is controlled to ≤2,000 pieces/cm<SP>2</SP>. Thus, even in a high strength thick steel plate in a class of 590 to 780 MPa, the toughness of the whole region of the HAZ in high heat input welding including, in particular, the weld heat affected zone in the vicinity of 3 to 5 mm from a melting line whose toughness is apt to decrease is remarkably improved.

COPYRIGHT: (C)2006,JPO&NCIPI

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com