Cleaning clamp for wafer carrying bench of semiconductor machine

A wafer stage, semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of difficult removal of impurities, reduced cleaning quality, and deep wafer stage depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further recognize and understand the features, objectives and functions of the present invention, the accompanying drawings are hereby described in detail.

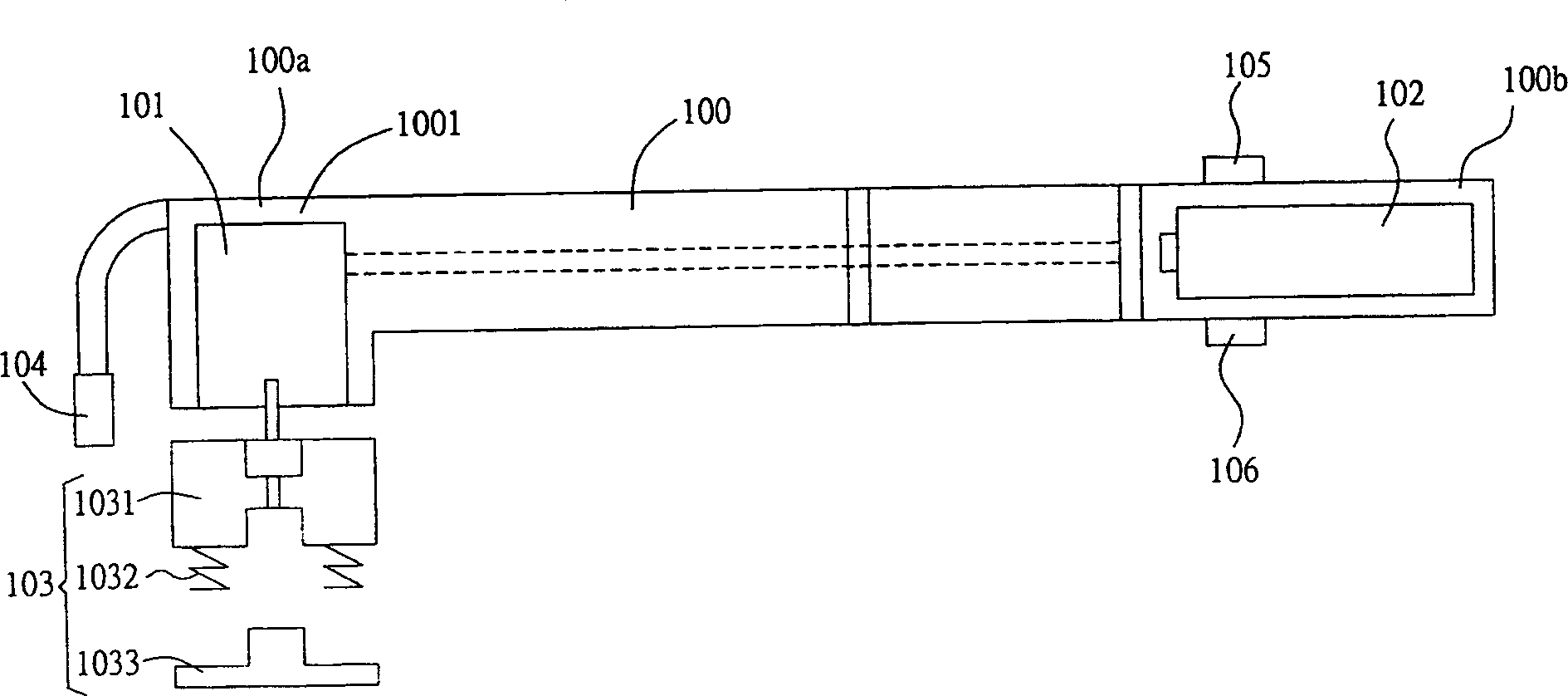

[0028] Such as figure 1 As shown, it is a schematic diagram of a preferred embodiment of the wafer stage cleaning jig of the semiconductor machine of the present invention, wherein the cleaning jig of the present invention mainly includes: a main body 100, a driving device 101 located in the main body 100, and a power supply The supply device 102 , and a cleaning module 103 interconnected with the driving device 101 and the power supply device 102 . , and the main body part 100 has a corresponding cleaning module end 100a and a handle end 100b, and the cleaning module is arranged on the cleaning module end 100a. In addition to fixing the length of the fixture between the cleaning module end 100a and the handle end 100b, for example, a telescopic rod can be used to freely adjust the length of the telesc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com