Horizontal downwards regulating three-roller plate bending machine

A technology of horizontally lowering and rolling, which is applied in the field of adjusting and moving mechanism of a horizontally lowering three-roller plate rolling machine, can solve the problems of inability to adjust the center distance, poor quality of rolled thin steel plates, poor quality of rolled thick steel plates, etc. Simple, high-quality, easy to manufacture, install, use and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

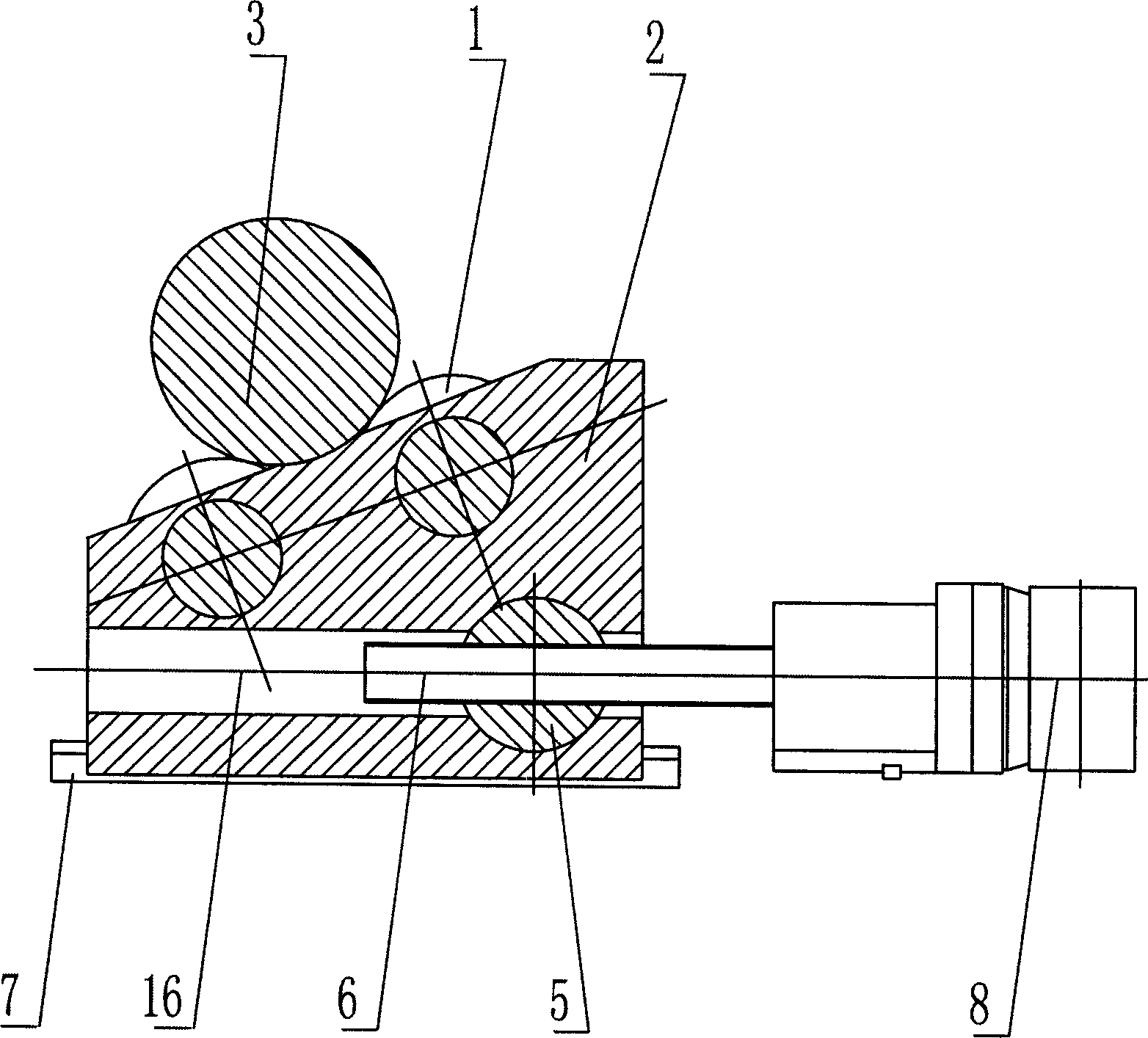

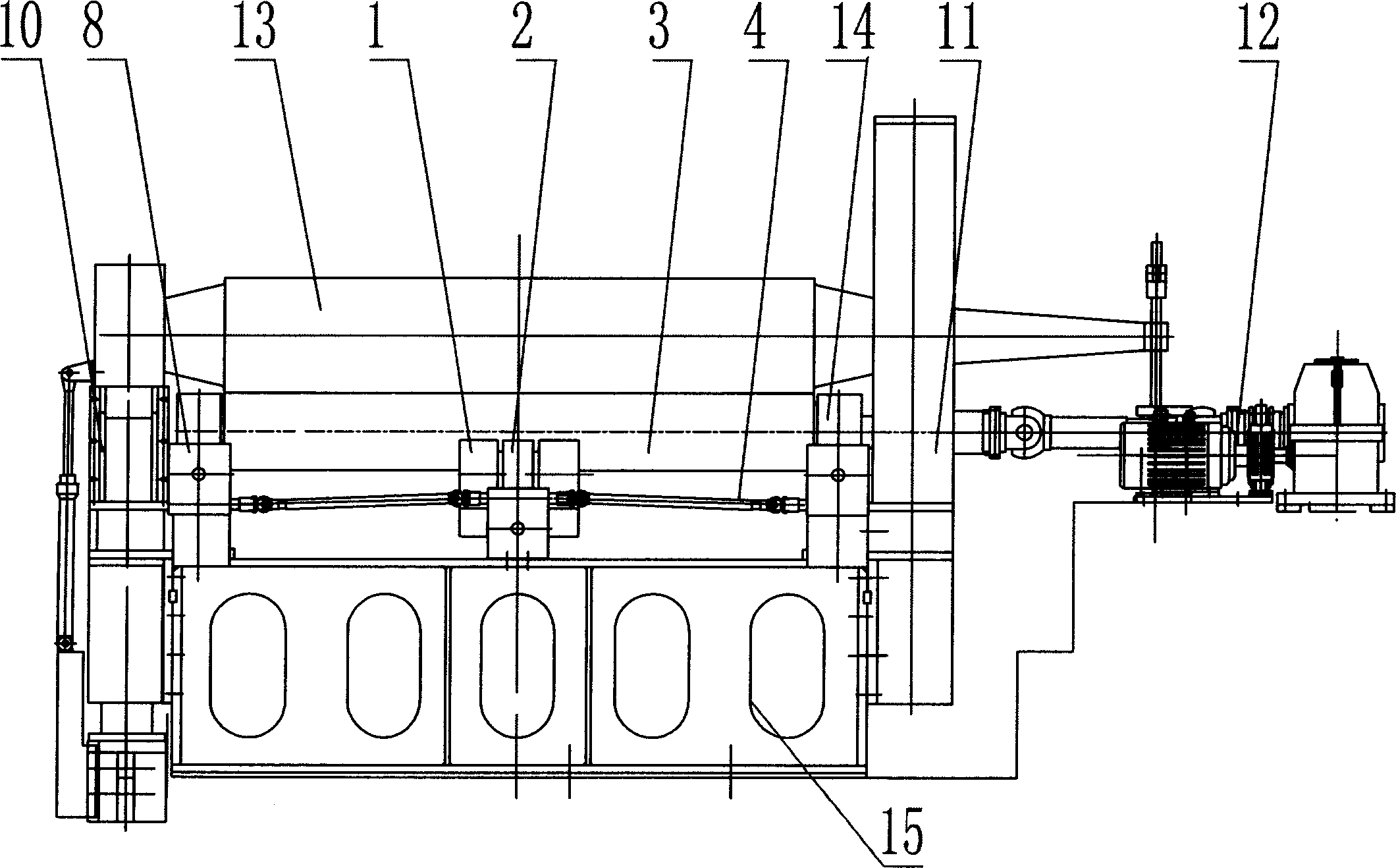

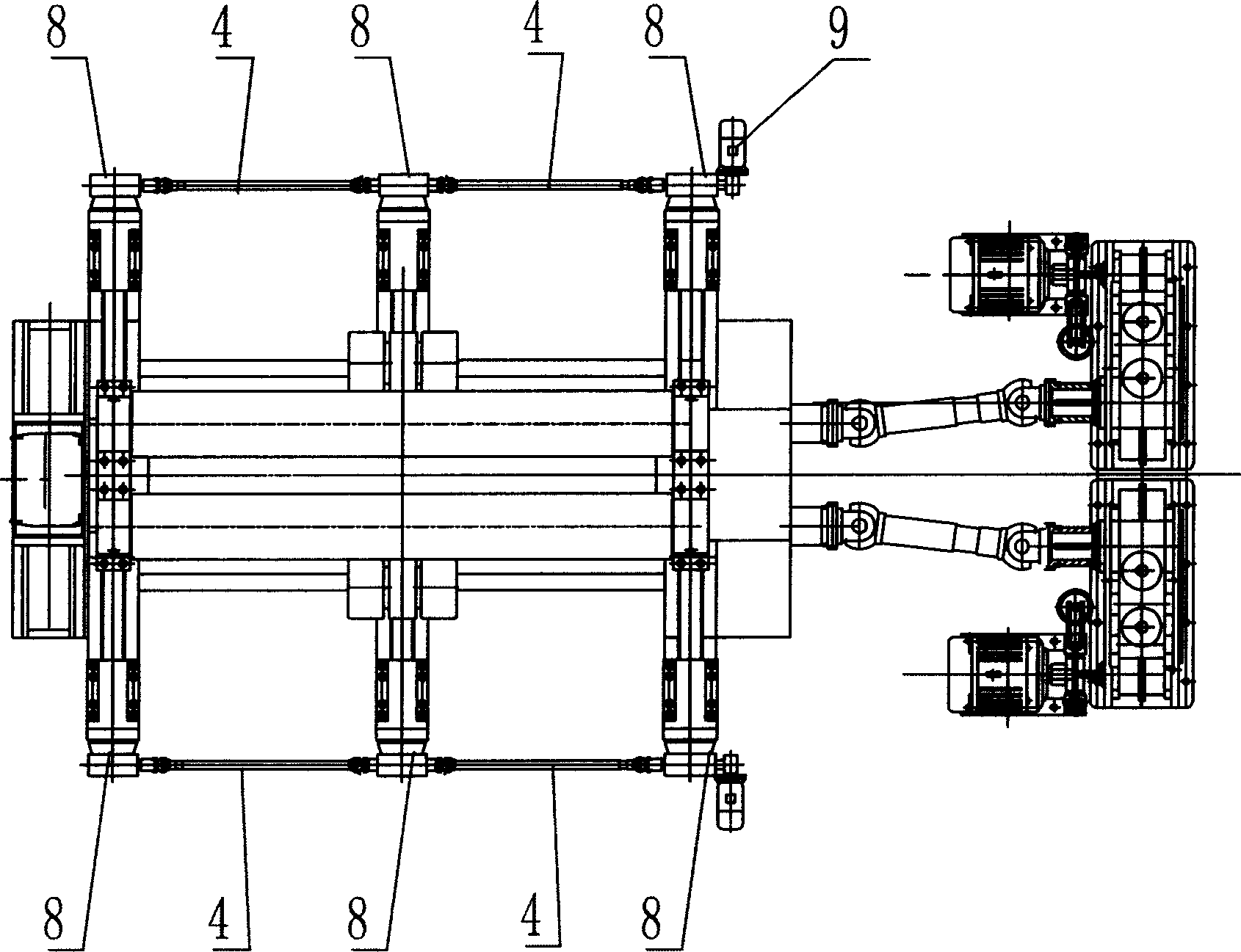

[0010] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1 to Figure 3 As shown, the present invention discloses a horizontal down-adjustment three-roll plate bending machine, which includes a lower roll bearing housing 14, a back-up roll housing 2, an adjustment device 8, a shaft coupling 4, and a motor 9. The lower roll bearing housing 14 And the two sides of the support seat 2 are symmetrically equipped with a horizontal movement mechanism. The horizontal movement mechanism is to install an adjustment device 8 on the side of the lower roller bearing seat and the support roller seat, and a coupling is installed between multiple adjustment devices. 4. A motor 9 is installed on the outside of a side coupling, and a through hole 16 or a blind hole is provided under the lower roller bearing seat and the support roller seat, and a round hole is provided at the intersection perpendicular to the center line of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com