Patents

Literature

72results about How to "Meet the needs of the market" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Single-component heat-curing liquid silicone rubber and preparation method thereof

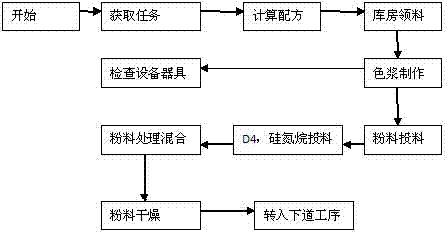

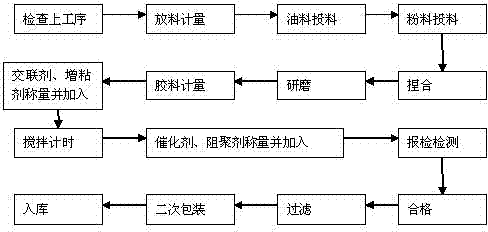

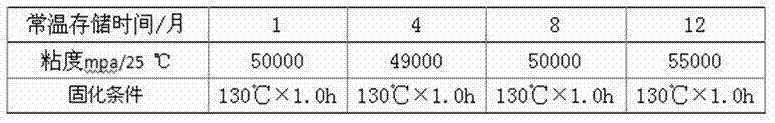

The invention belongs to the field of liquid silicone rubber, and particularly relates to single-component heat-curing liquid silicone rubber and a preparation method thereof. Ethenyl polysiloxane is used as base rubber, hydrogen polysiloxane is used as a cross-linking agent, a complex of transition metal platinum is used as a catalyst, an alkynol mixture is used as an efficient polymerization inhibitor, aluminum oxide and aluminium nitride are used as heat conductive fillers, a silane coupling agent is used as a tackifier, aluminium hydroxide is used as a fire retardant, and fumed silica is used as a reinforcing agent. As a process is strictly controlled, and a process route that raw materials are treated and dried in advance, and mixed at room temperature to prepare the rubber is adopted, the low-viscosity single-component heat-curing silicone rubber is prepared. The fire retardant single-component heat-curing liquid silicone rubber can be stored for a long term at normal temperature, is low in viscosity, single in component, good in heat conductivity and temperature tolerance, and good in adhesion with a base material.

Owner:CHENGDU TALY TECH CO LTD

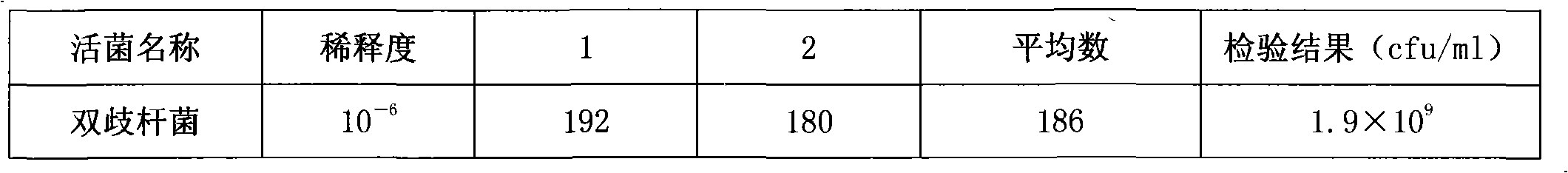

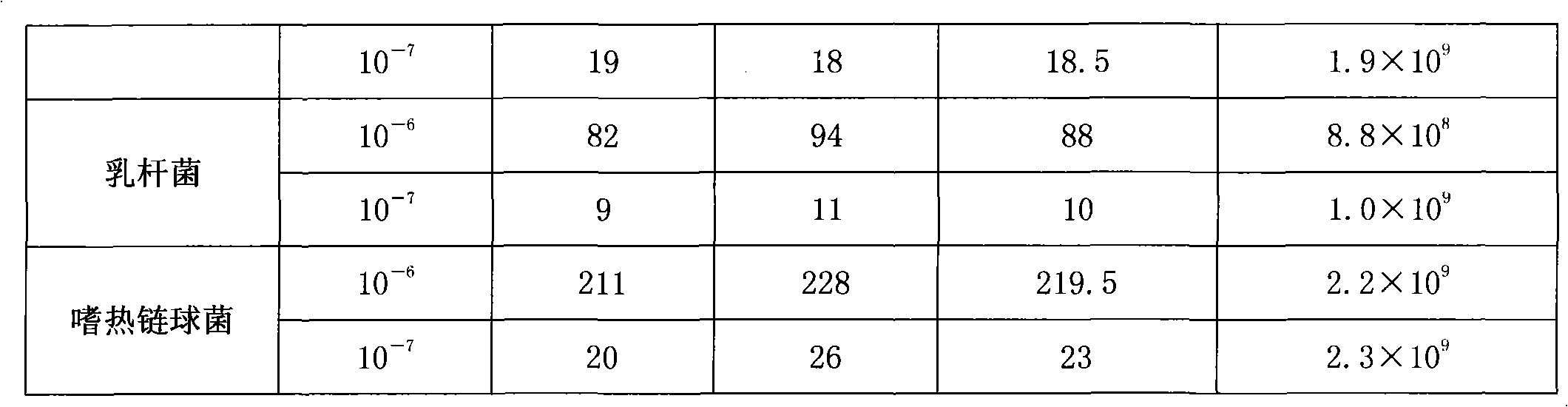

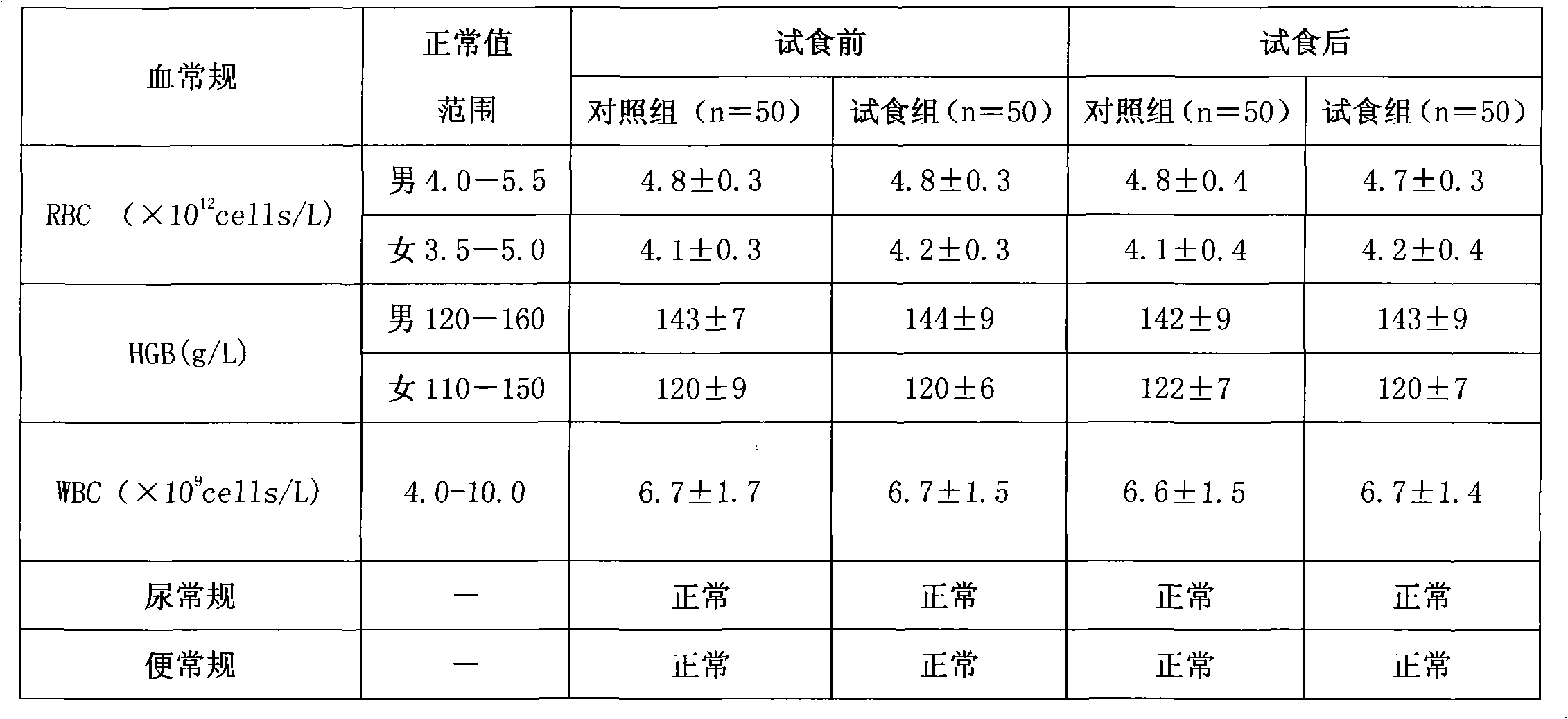

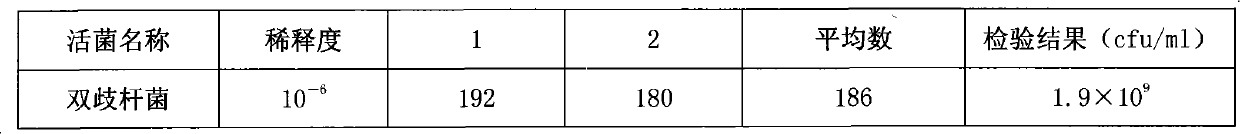

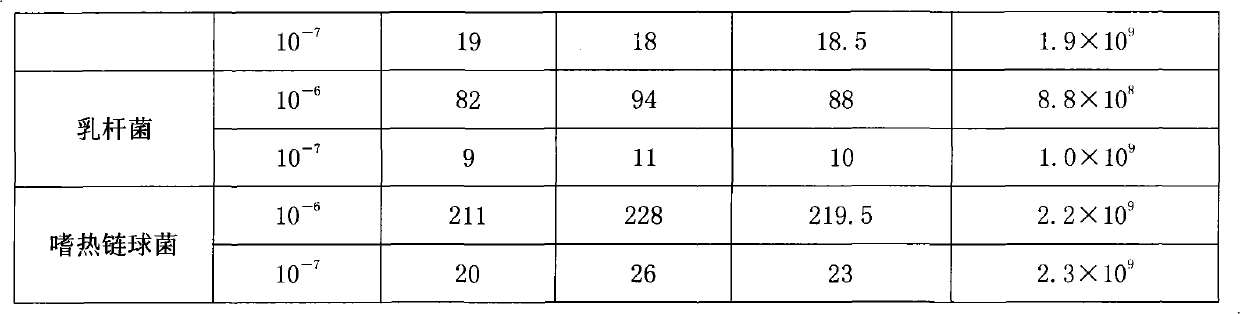

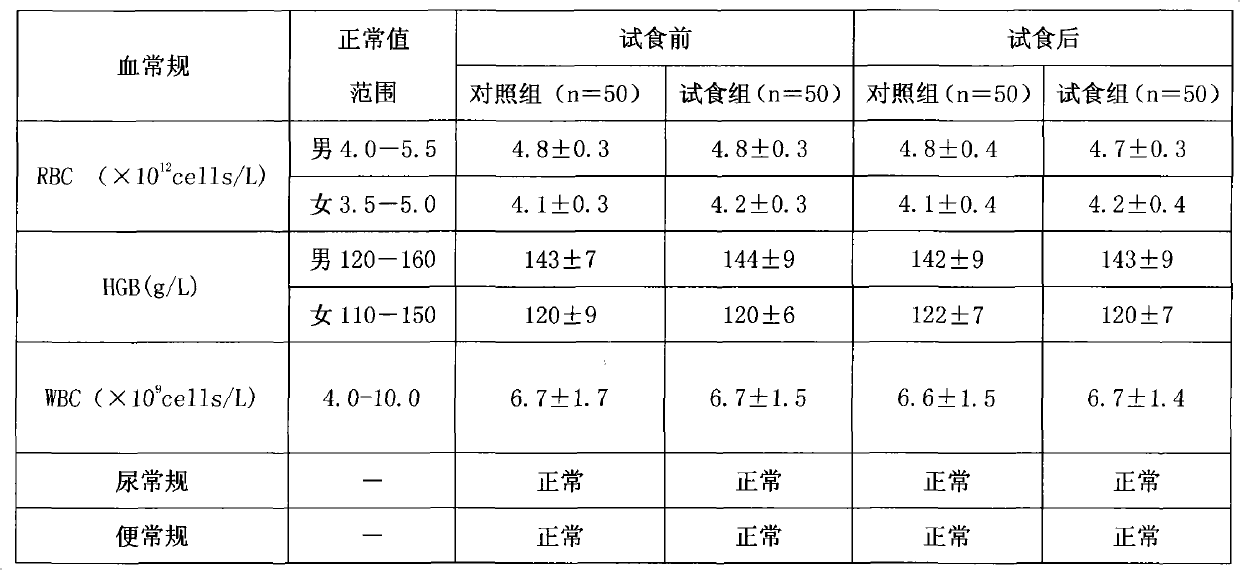

Probiotic composition and preparation thereof

ActiveCN101897729AAvoid infectionImprove proliferative abilityOrganic active ingredientsBacteria material medical ingredientsBifidobacteriumProbiotic

The invention relates to a probiotic composition and a preparation. The composition consists of three main probiotics, namely lactobacillus, bifidobacteria and streptococcus thermophilus. The composition can be regulated to be suitable for different intestinal canal characteristics of more people and meet the market requirement and has the advantages of safety, reliability and obvious effect.

Owner:天津金士力健康用品有限公司

Vespa Rheumatism Pain Relief Wine

InactiveCN102283918ASimple preparation processRich sources of medicineHeavy metal active ingredientsAnthropod material medical ingredientsWeaknessSciatica

The invention discloses a wasp rheumatic health-care wine for alleviating pain. The invention is characterized in that the wasp rheumatic health-care wine for alleviating pain is prepared by soaking wasps and 23 traditional Chinese medicines, including notopterygium root, heracleum hemsleyanum michaux, panicled swallowwort root, radix gentianae macrophyllae and the like, in 36-55 vol% pure white rice wine. The health-care wine has the functions of expelling wind and removing dampness, treating rheumatism and rheumatic diseases, alleviating pain and eliminating subsidence of swelling. The health-care wine is very suitable for treating arthralgia due to wind-cold-dampness, rheumatoid arthritis, chronic infectious arthritis, periarthritis humeroscapularis, limb pain, soreness and weakness ofthe waist and knees, limb numbness and other symptoms. When being drunk as a common beverage, the health-care wine has the effects of tonifying the kidney, strengthening the bone, relaxing muscles and tendons, activating the collaterals, treating sciatica and lumbar muscle strain and the like, and is a health-care medicinal wine with both treatment and health-care effects. The health-care wine issuitable for various people.

Owner:周衡

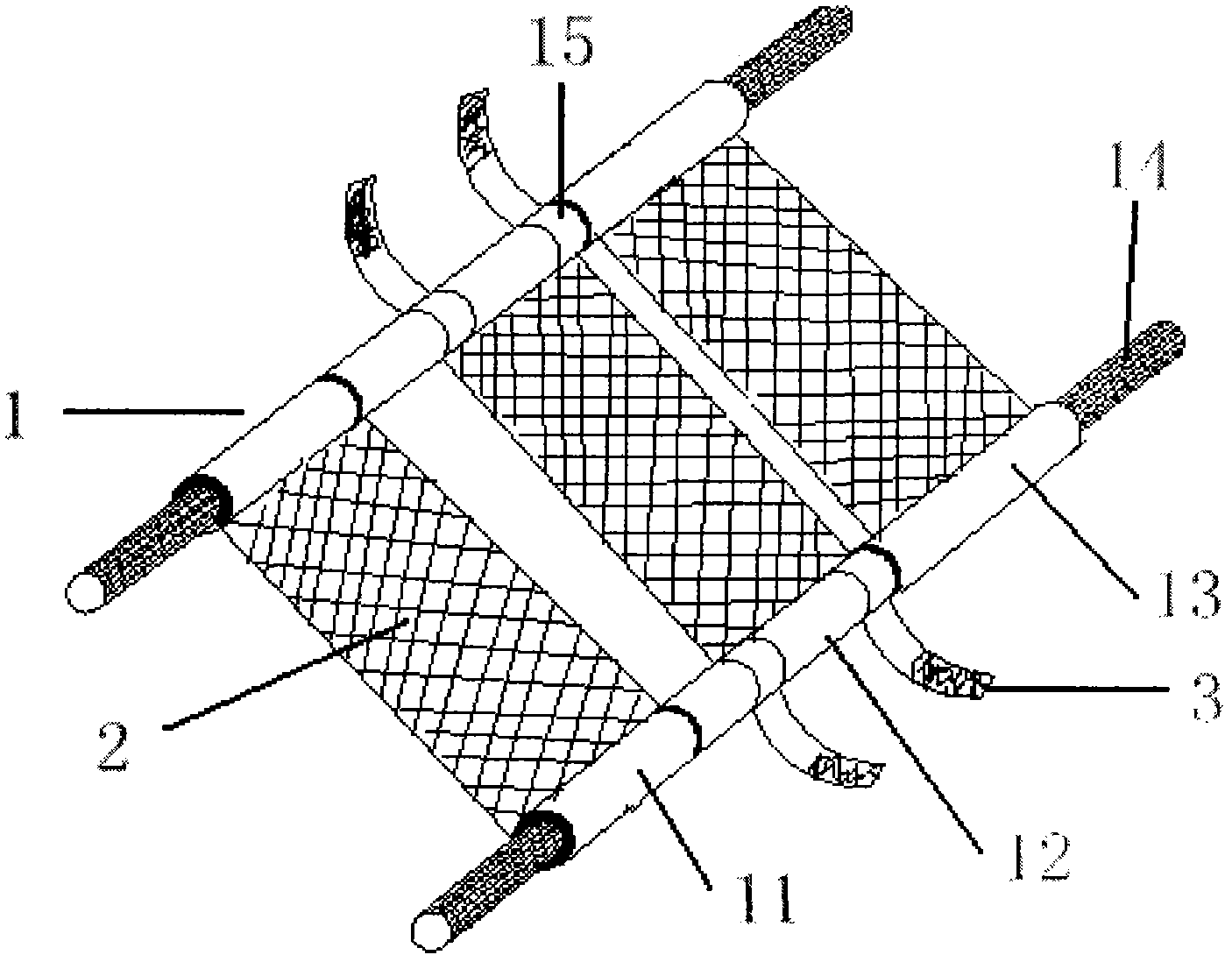

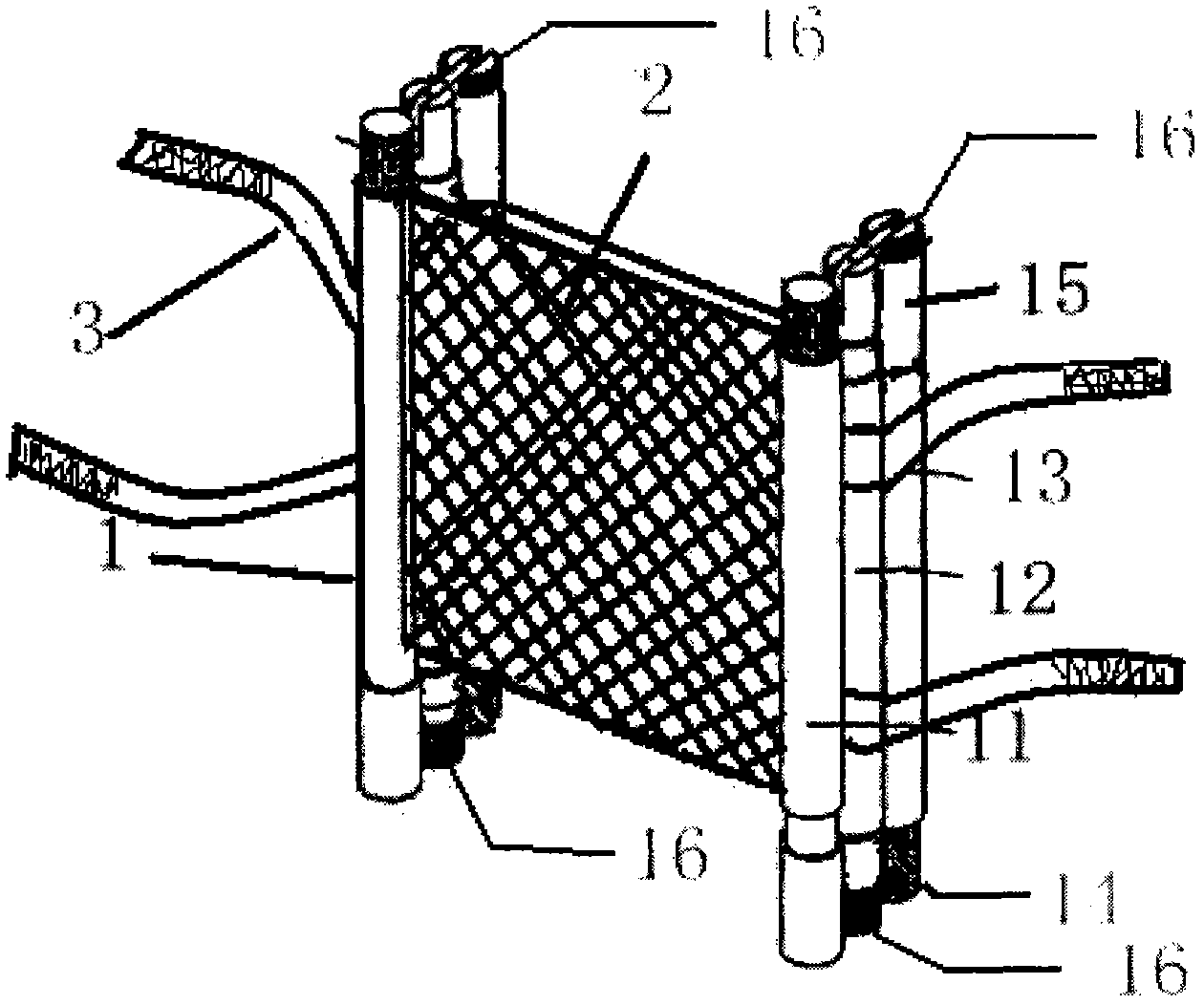

Foldable first-aid soft stretcher

The invention provides a medical first-aid tool and in particular relates to a foldable first-aid soft stretcher. The foldable first-aid soft stretcher comprises a foldable stretcher body, a net-shaped soft stretcher surface for the lying of a patient on the stretcher, and fasteners for binding the stretcher, wherein the stretcher body comprises three stretcher rods; the two connected rods are connected by a threaded sleeve pipe. According to the stretcher, the problems of inconvenience for carrying and high weight of a conventional stretcher are solved.

Owner:王芸

Method for producing silverwork through sleave process

ActiveCN102602222AOvercome the complicated processOvercome the thin and easy to breakSpecial ornamental structuresMaterials scienceWelding

The invention discloses a method for producing a silverwork through a sleave process. The method comprises the following steps of: twisting a silver wire into a filament, pressing and pinching, filling the pressed and pinched silver wire into a silver frame, striking, welding, molding and the like. The sleave process of the silverwork does not only have the delicate degree of the conventional weaving process, but also is that the silver wire is pressed and pinched into a sleave to fill the silver frame, and thus the silver wire can be randomly moulded and is not easy to break, a sleave decoration object has large plasticity, the appearance is simple and fashional and the silver decoration object looks like relatively full and unique.

Owner:贵州今彩民族文化研发有限公司

Tissue culture rapid-propagation method of beaucarnea recurvata

InactiveCN104585037AIncrease the multiplication factorImprove seedling qualityPlant tissue cultureHorticulture methodsObserved SurvivalCulture mediums

The invention relates to a tissue culture rapid-propagation method of beaucarnea recurvata. The tissue culture rapid-propagation method comprises the following steps: (1) placing a disinfected beaucarnea recurvata seed as an explant into an MS germination culture medium for germination induction to obtain a sterile test-tube seedling; (2) placing the test-tube seedling into an MS cluster bud culture medium for propagation culture to obtain cluster buds; (3) placing the cluster buds into an MS strong seedling culture medium for culture to obtain a strong plant; (4) placing the strong plant into a 1 / 2MS rooting culture medium for culture to obtain a rooting seedling; (5) carrying out seedling adaptation on the rooting seedling, and transplanting to a sand bed to grow for one month, and then transplanting to a field. According to the tissue culture rapid-propagation method, the multiplication coefficient of the obtained cluster buds is 20-30 times, the rooting rate of an obtained tissue culture seedling is more than 95%, and the survival rate of a transplanting seedbed is more than 90%, so that the problem of industrialized seedling culture of the beaucarnea recurvata is effectively solved.

Owner:GUANGXI BOTANICAL GARDEN OF MEDICINAL PLANTS

Radix gentianae dahuricae cultivation method

A radix gentianae dahuricae cultivation method comprises the following steps of land selection and preparation, sowing and seedling raising, transplanting, field management, pest control and prevention, harvesting and processing.Introduction and domestication are performed on radix gentianae dahuricae wild resources, large-scale artificial cultivation is achieved, normalized and standardized production technology is promoted, rapid growth needed by radix gentianae dahuricae is met, and resource sustainable utilization of the radix gentianae dahuricae is maintained.

Owner:GUANGXI BOTANICAL GARDEN OF MEDICINAL PLANTS

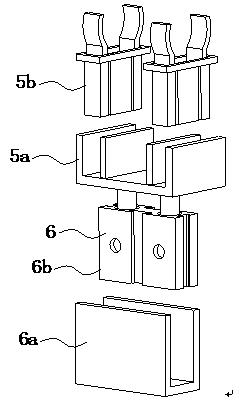

LED (light emitting diode) screen splicing structure and LED screen

ActiveCN107248381ACompact designEasy to adjust the angleSheet joiningIdentification meansEngineeringMechanical engineering

The invention discloses an LED (light emitting diode) screen splicing structure and an LED screen. The LED screen splicing structure comprises a first box and a second box, the first box and the second box are spliced mutually, the first box comprises a first side wall facing the second box, the second box comprises a second side wall opposite to the first side wall, the first side wall is provided with a plurality of limiting faces in different angles, the second side wall is provided with a slide groove corresponding to position of the limiting faces, and a wedged slider is movably arranged in the slide groove. The first box and the second box are fixedly connected through a spring connector penetrating the wedged slider, and an included angle between the first box and the second box is defined by the wedged slider and the limiting faces jointly. Angle nonuniformity in splicing is realized by matching of the wedged slider and the limiting faces, assembly and fastening of the two boxes are realized by the aid of a spring connection lock, and easiness in angle adjustment, mechanism simplicity, steadiness in connection for use, less proneness to loosing in repeated disassembly, part design and cost reduction, easiness in processing and accordance with market requirements are realized.

Owner:LKK DESIGN SHENZHEN

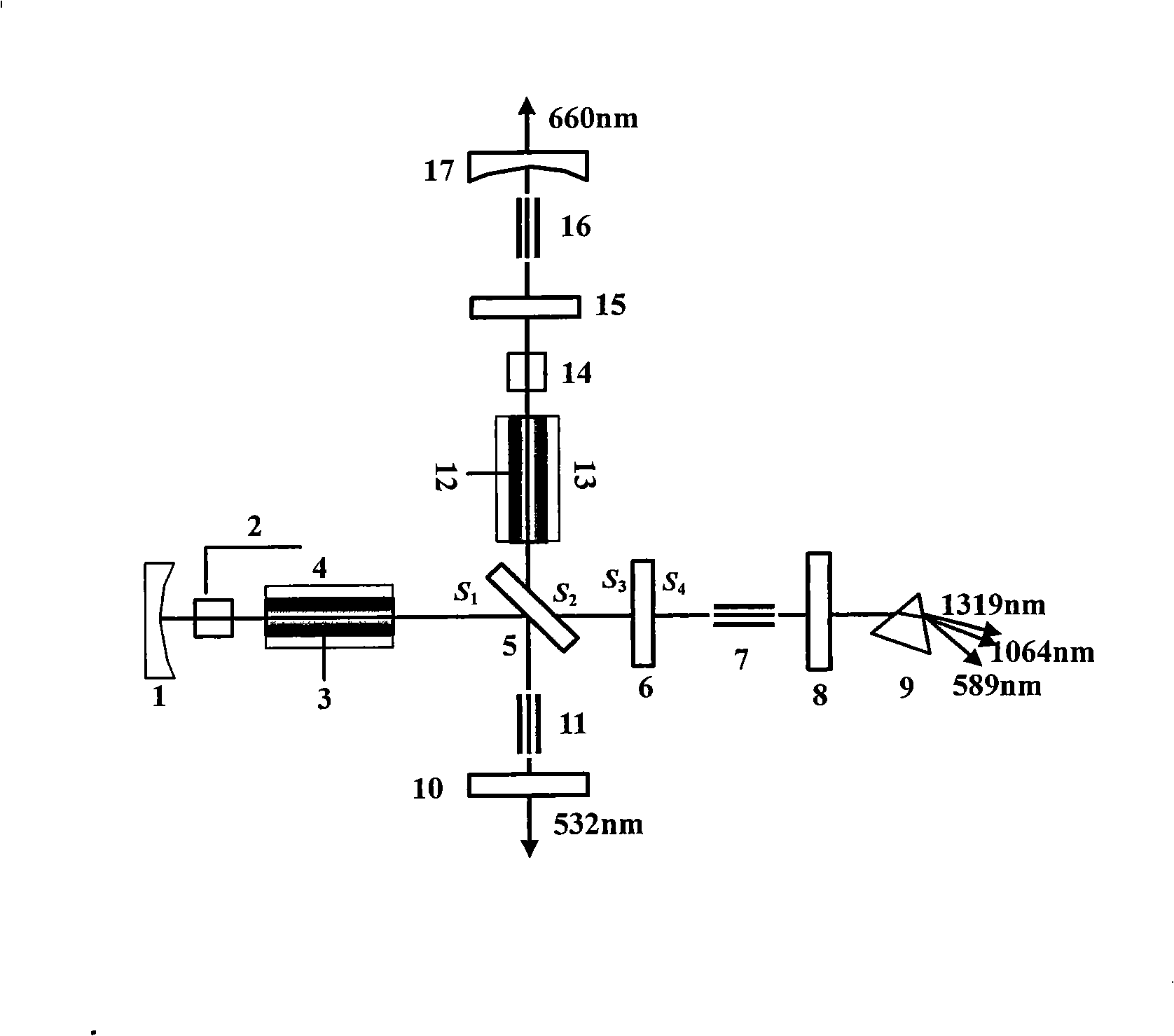

Full-solid state five-wavelength simultaneously outputting laser device and 5-wavelength laser generation method

InactiveCN101345389AReduce output powerMany wavelengthsOptical resonator shape and constructionLaser arrangementsNonlinear opticsFundamental frequency

The invention discloses a laser facility of all-solid-state five-wavelength lasers simultaneous output and a laser production method. The five-wavelength lasers, that is, infrared of 1.3 mum wavelength, infrared of 1.0 mum wavelength, green light of 0.5 mum wavelength, yellow light of 0.5 mum wavelength and red light of 0.6 mum wavelength, are simultaneously output using a Nd<3+>-doped laser crystal as working substance and a composite resonator of + shape by combining nonlinear optics frequency translation technology with acousto-optically Q-switched technology as well as controlling the polarization direction of fundamental frequency lasers with different wavelengths by a polarization beam splitter. The fundamental frequency lasers with different wavelengths and polarization directions respectively form oscillation in each relatively independent resonant cavity and each beam of light can be adjusted independently. The laser facility has advantages of multiple wavelengths, high efficiency, compact structure, low running cost, convenient and flexible adjustment and safe work, and is widely used in the field of laser medicine, laser color display, laser entertainment, astronomy, national defense and scientific research.

Owner:NORTHWEST UNIV(CN)

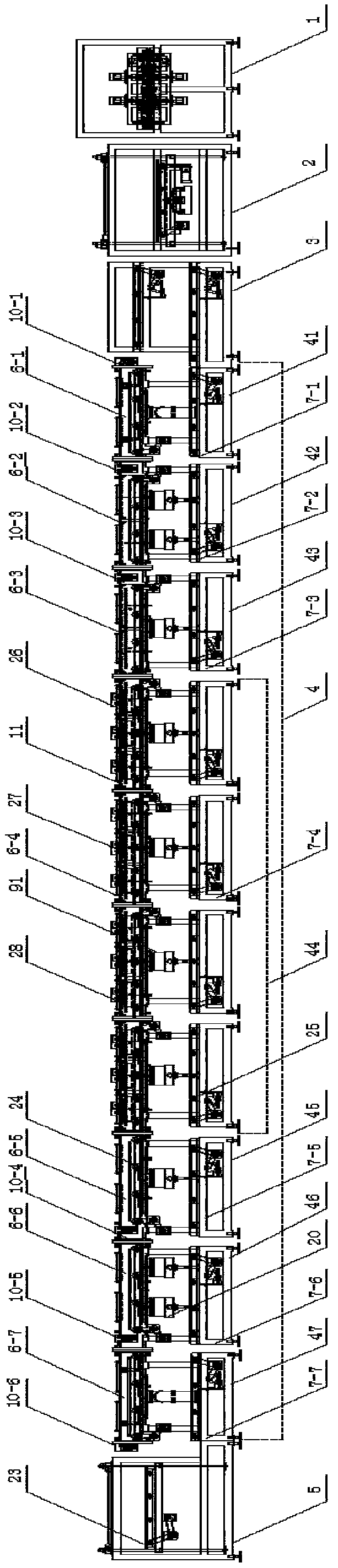

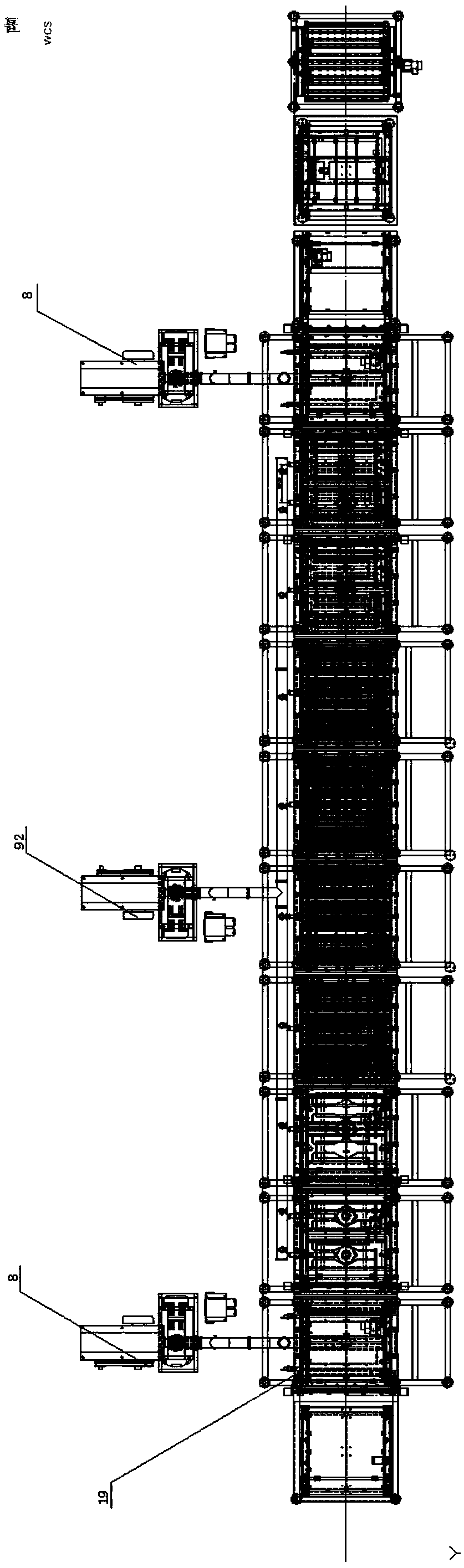

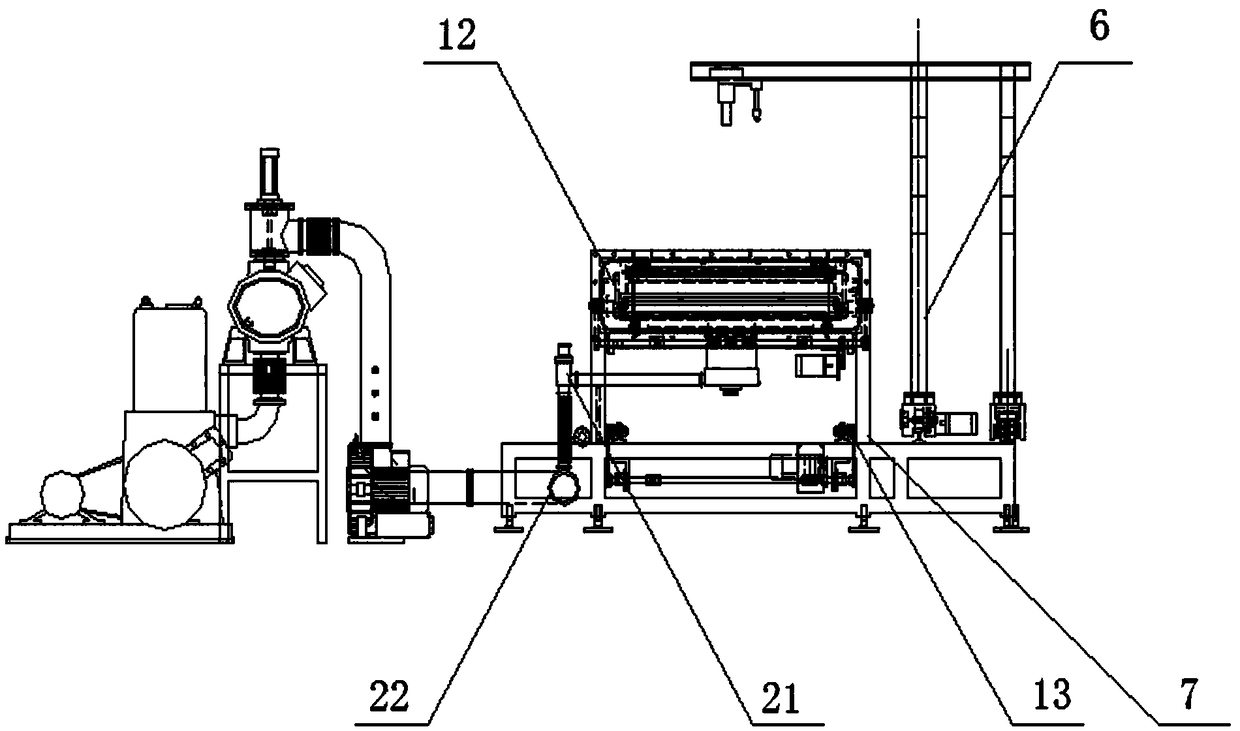

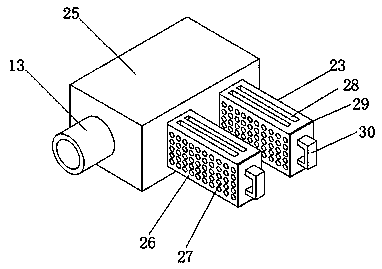

Production line of neodymium-iron-boron surface metallized magnetic-control sputtering coating film

InactiveCN108977783AReduce usageReduce exposureVacuum evaporation coatingSputtering coatingSputteringProduction line

The invention discloses a production line of a neodymium-iron-boron surface metallized magnetic-control sputtering coating film. The production line comprises an overturning module, a hoisting module,a sheet feeding and discharging module, a vacuum film plating module and a sheet discharging hoisting module, wherein the vacuum film plating module is composed of a plurality of vacuum cavities anda plurality of cavity brackets; all the vacuum cavities are mounted on a cavity bracket; the cavity body is internally provided with an inner conveying system; a maintenance travelling crane is arranged above the vacuum cavity; a substrate returning system is mounted on the cavity brackets; the vacuum film plating module is divided into seven sections including an inlet vacuum section, an inlet buffering vacuum section, an inlet transition vacuum section, a film coating technology vacuum section, an outlet transition vacuum section, an outlet buffering vacuum section and an outlet vacuum section. By adopting the production line, large-batch continuous production of small-size ceramic sheet magnetic-control sputtering metallized coating films is realized, and the capacity per day can reach60000 to 100000 pieces; especially, the production line is suitable for coating films of surface double-faced metallized function films of neodymium-iron-boron magnetic ceramic sheets and can meet marketization requirements.

Owner:WUHAN KERUIDA VACUUM TECH CO LTD

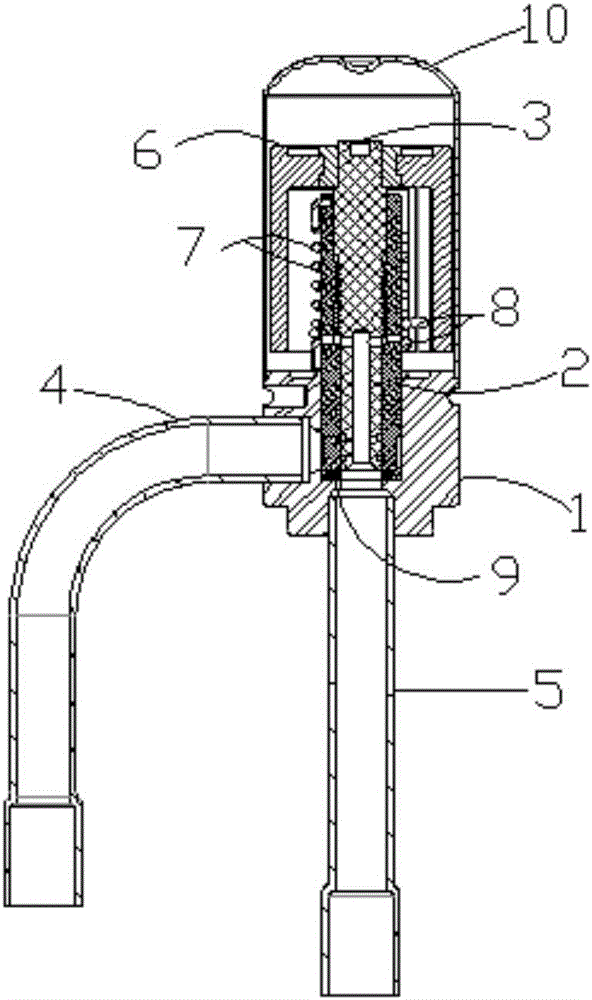

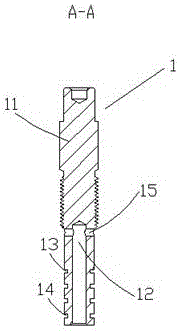

Electronic expansion valve with precision controlled through flow

ActiveCN106678421AHigh control precisionRelieve stressOperating means/releasing devices for valvesEfficient regulation technologiesStraight tubeElectronic expansion valve

The invention discloses an electronic expansion valve with precision controlled through flow. The electronic expansion valve with the precision controlled through the flow comprises a valve base and a valve rod; a through groove which is through in an up-down manner is formed in the valve base; a matched bearing pedestal is inserted into the through groove and comprises a base body in which a penetrating through hole is formed; the through hole is matched with the valve rod; an internal thread segment is formed on the middle portion of the inner wall of the through hole; a matched straight pipe is welded to the bottom end of the through groove; a side face hole communicated with the through groove is formed in the outer wall of the valve base; a matched bent pipe is welded to the side face hole; an isolation sleeve is welded to the outer wall of the valve base; and a magnetic rotor is arranged outside the upper end of the valve rod. The electronic expansion valve with the precision controlled through the flow is characterized in that a second ring groove and a rectangular valve port are formed in the outer wall of a lower end port of the base body. The electronic expansion valve with the precision controlled through the flow can overcome the defects in the prior art, can eliminate the lateral pressure generated by gas borne by the valve rod, and can also make the flow control precision improved, control and adjustment of a system are facilitated, and meanwhile cost is reduced so that the market requirement can be met.

Owner:ZHUJI YIBA ELECTRONICS VALVE

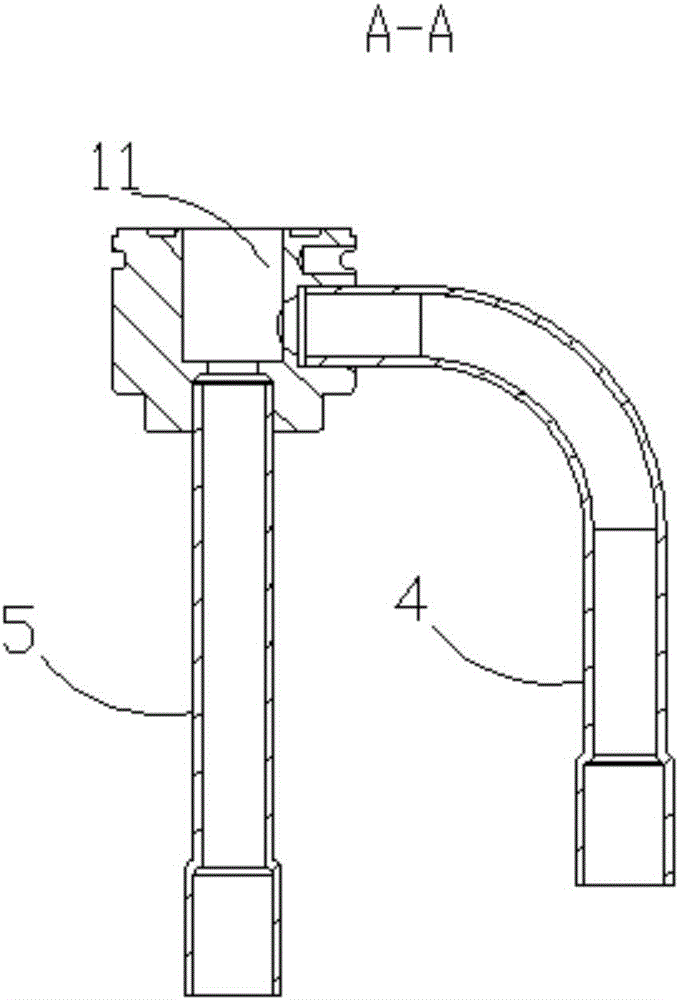

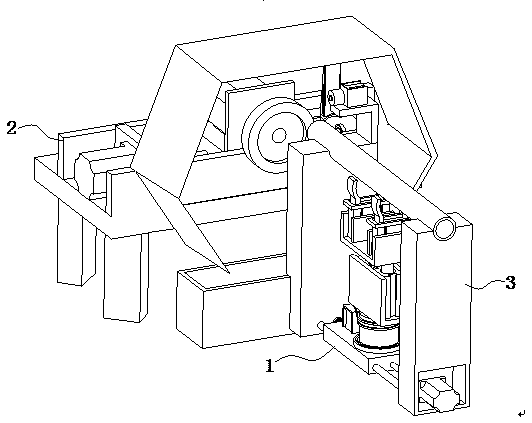

Pipe orifice deburring device

InactiveCN107584357AAvoid damageFacilitates deburring workEdge grinding machinesGrinding drivesEngineeringMachining

The invention relates to the field of machining and in particular relates to a pipe orifice deburring device. The pipe orifice deburring device comprises a head-changing mechanism, a deburring mechanism and a supporting device, wherein the supporting device comprises a left supporting column and a right supporting column; the head-changing mechanism comprises a rotating assembly and a clamping assembly; grooves are formed in the tops of the left supporting column and the right supporting column; the rotating assembly comprises a rotary roller and a push assembly; a shifting assembly is arranged at the bottom of the rotary roller; the deburring mechanism comprises a clamping assembly and a deburring assembly; the deburring assembly comprises a supporting table and a sliding assembly; the sliding assembly comprises a left supporting plate and a right supporting plate; a second lead screw is arranged between the left supporting plate and the right supporting plate; a second lead screw sliding table is arranged on the second lead screw in a sleeving manner; and a first motor sleeving with a steel brush wheel is arranged on the top of the second lead screw sliding table. According to the pipe orifice deburring device disclosed by the invention, after deburring is completed at one end of a workpiece, the other end of the workpiece can be shifted out by the head-changing mechanism, time and labor can be saved, and the requirements in the market are met.

Owner:楚宗美

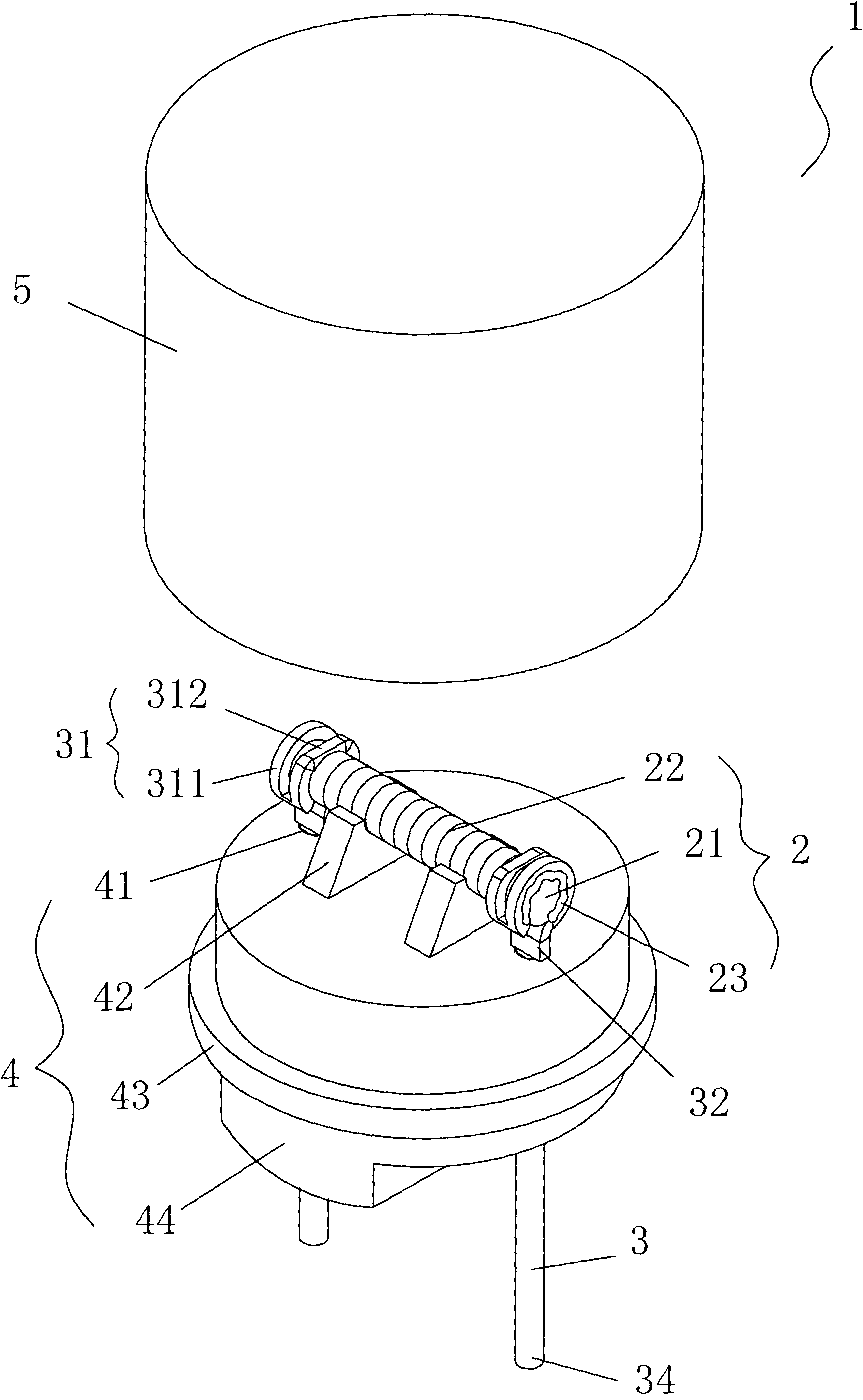

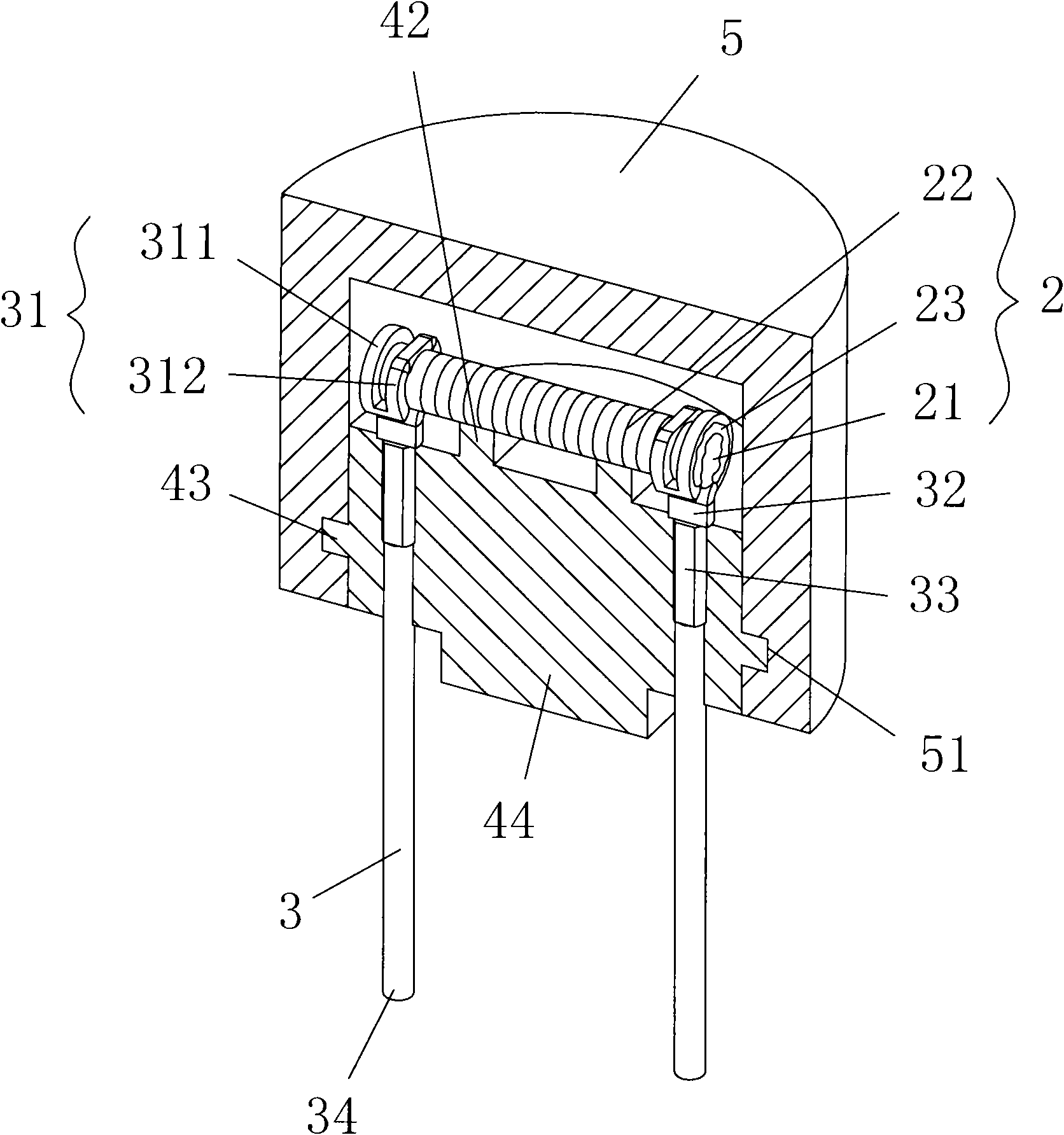

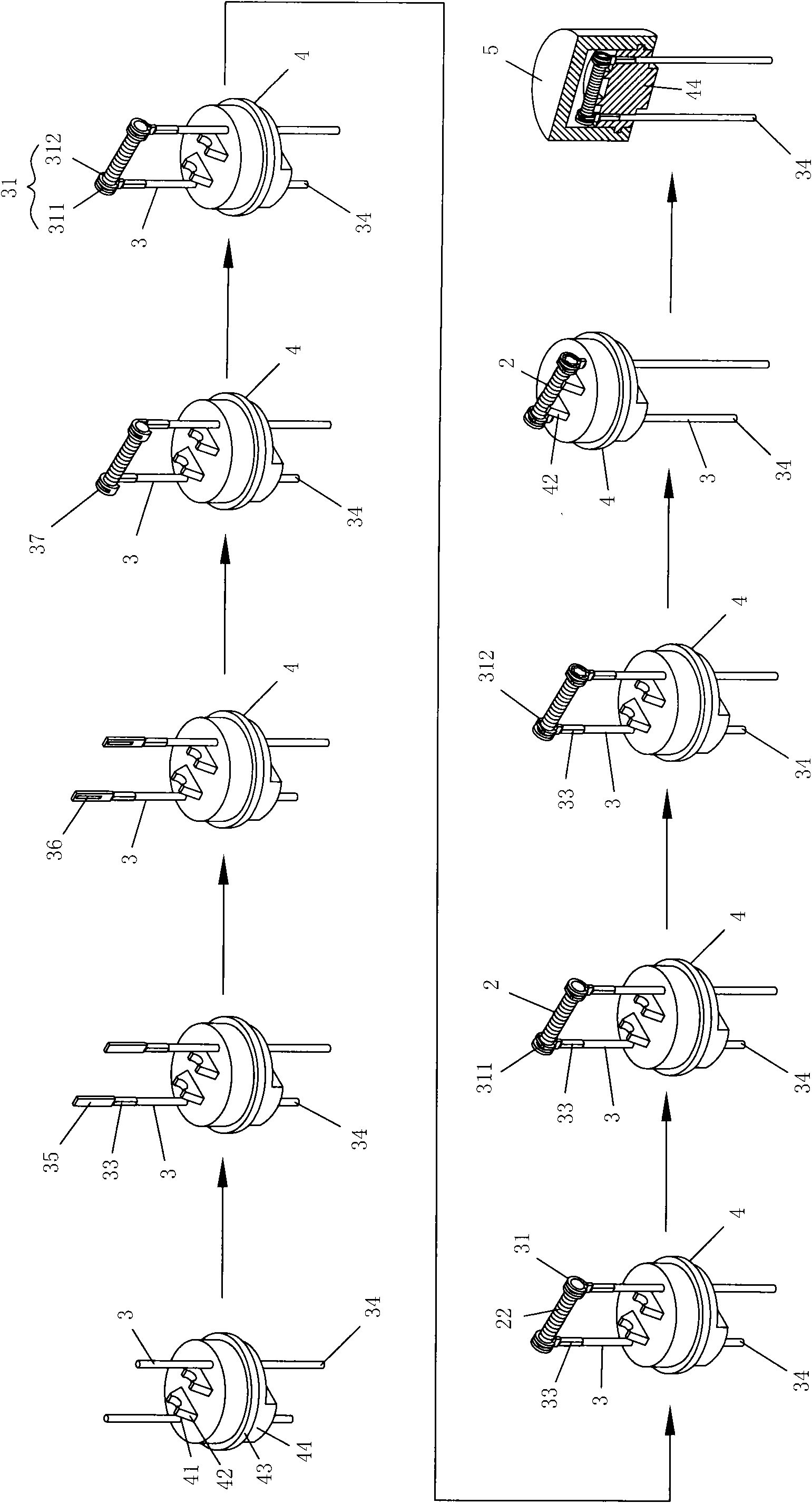

Manufacturing method and finished product of micro-fuse

The invention relates to a micro-fuse which comprises a melting part, two electrode parts, a seat body and a cover body, wherein the melting part is provided with a column body surrounding a melting wire body to form a surrounding melting wire; one end of the electrode parts is provided with two ring bodies with closed end parts and bearing and fixing surfaces; the seat body is provided with through holes for the two electrode parts to pass through, the upper end of the seat body is provided with a bearing platform, sides of the seat body are provided with buckling rings, the lower end of the seat body is provided with a positioning block; and the cover body is buckled on the seat body to form a close space. The invention also relates to a fabricating method of the micro-fuse, which comprises the following steps: providing the seat body, arranging the two electrode parts in a penetrating way; forming planes and the bearing and fixing surfaces at the end parts of the two electrode parts, and bending through hole grooves to form the two ring bodies, wherein the inner ring body is pressed and fixedly connected to the inner side of the melting part, the outer ring body is welded and fixedly connected to the end part of the melting part; bearing the melting part by the bearing platform at the upper end of the seat body; and forming the close space by the cover body correspondingly covering the seat body. The micro-fuse has high yield, high quality and high safety.

Owner:邱鸿智

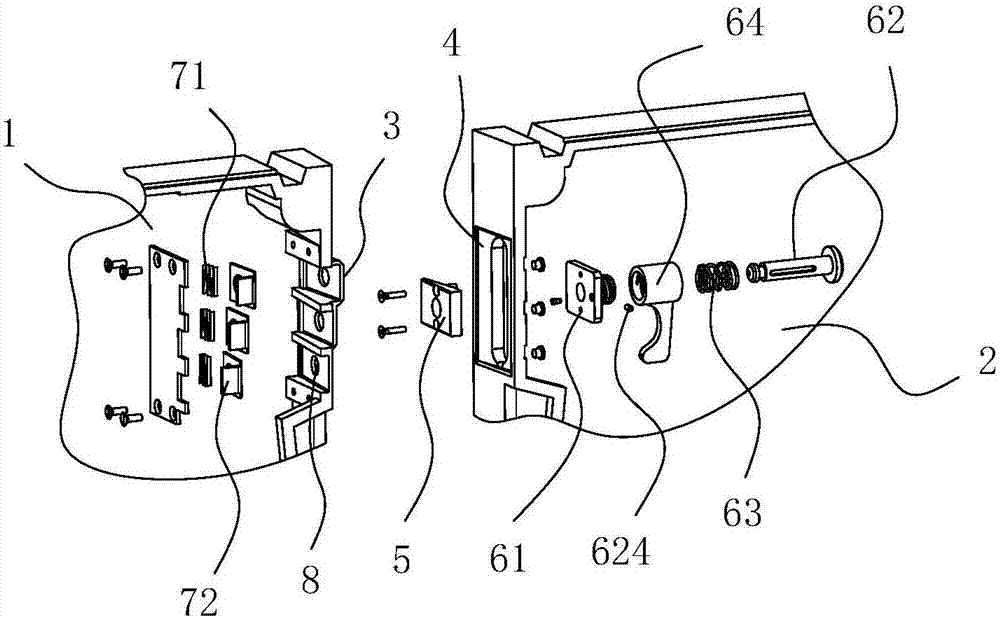

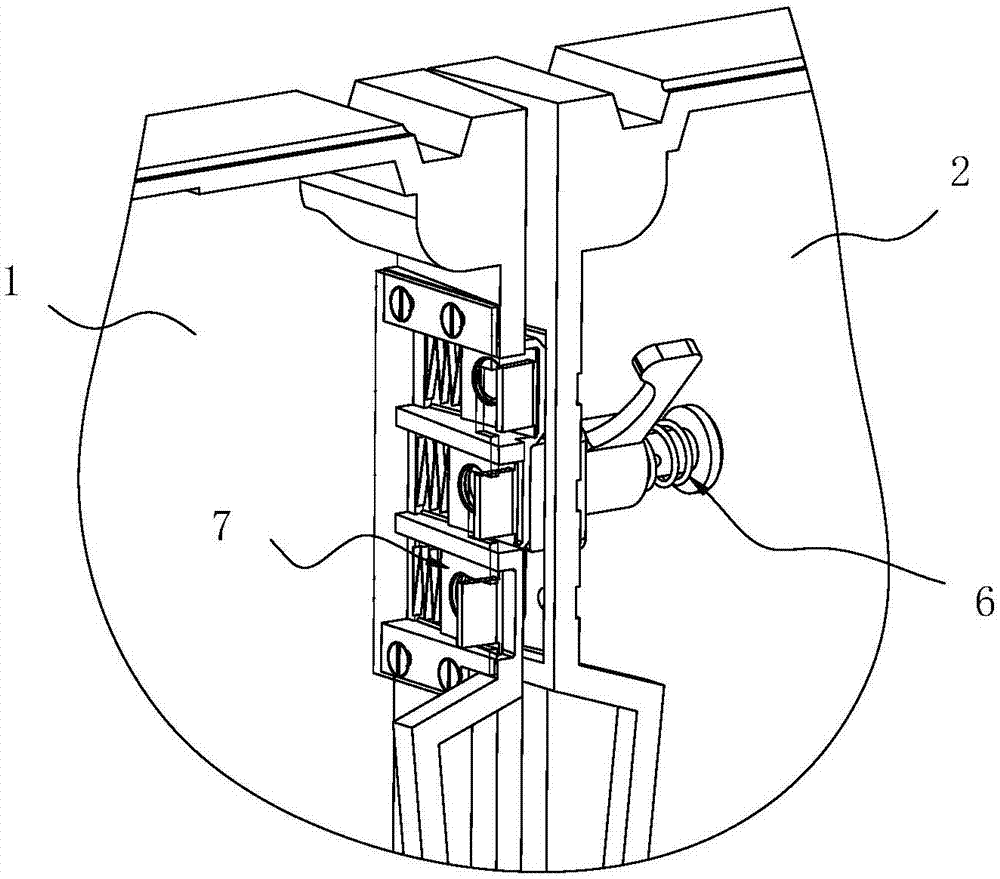

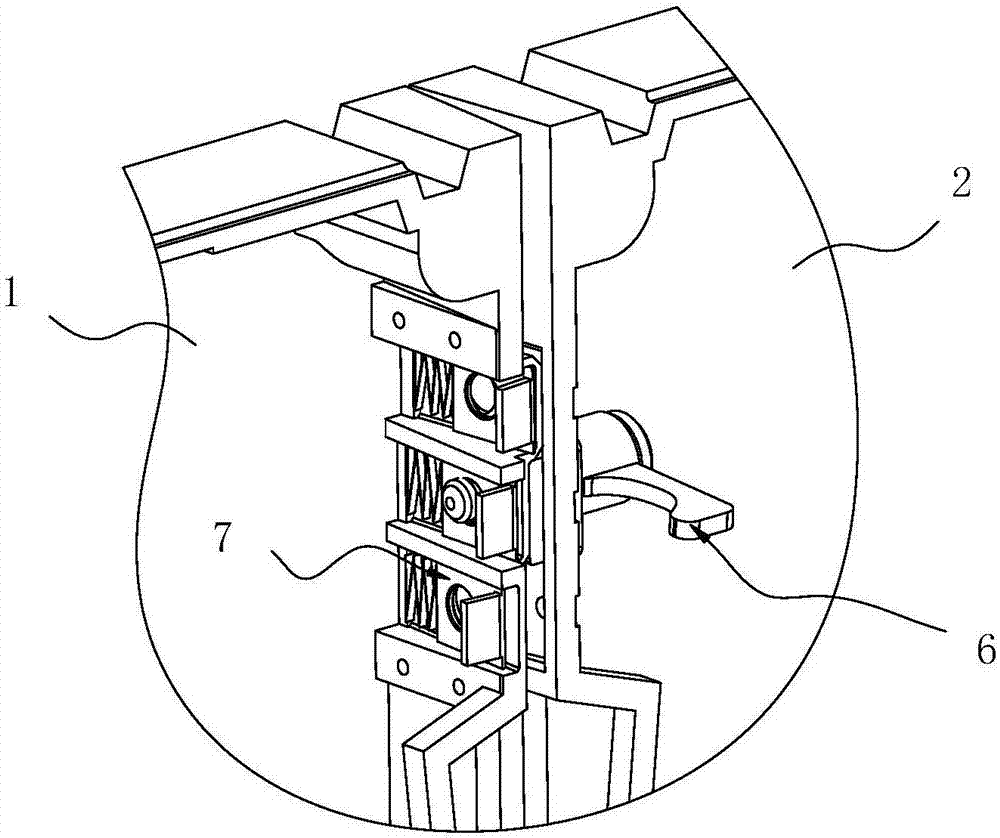

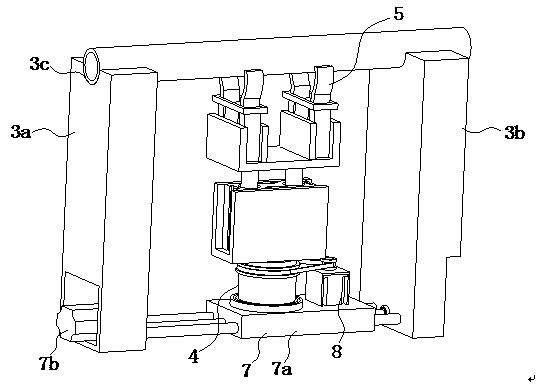

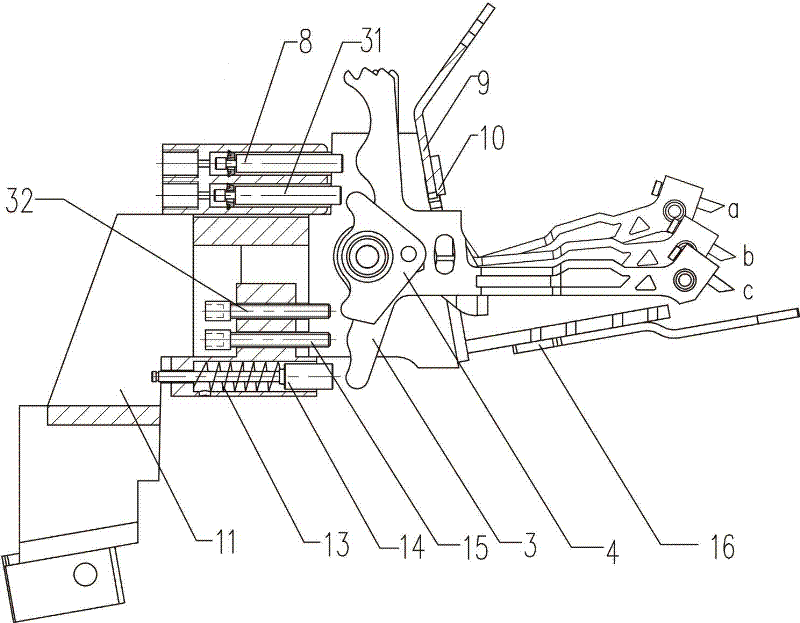

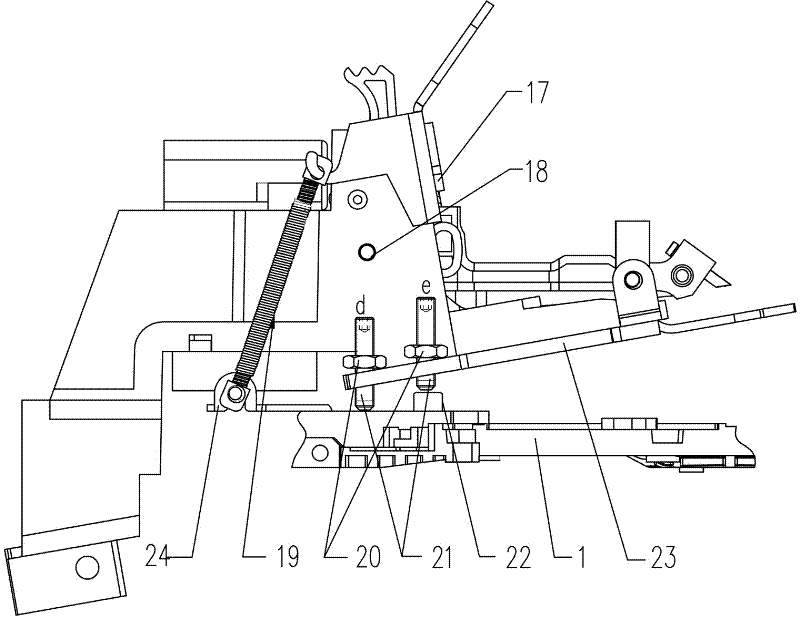

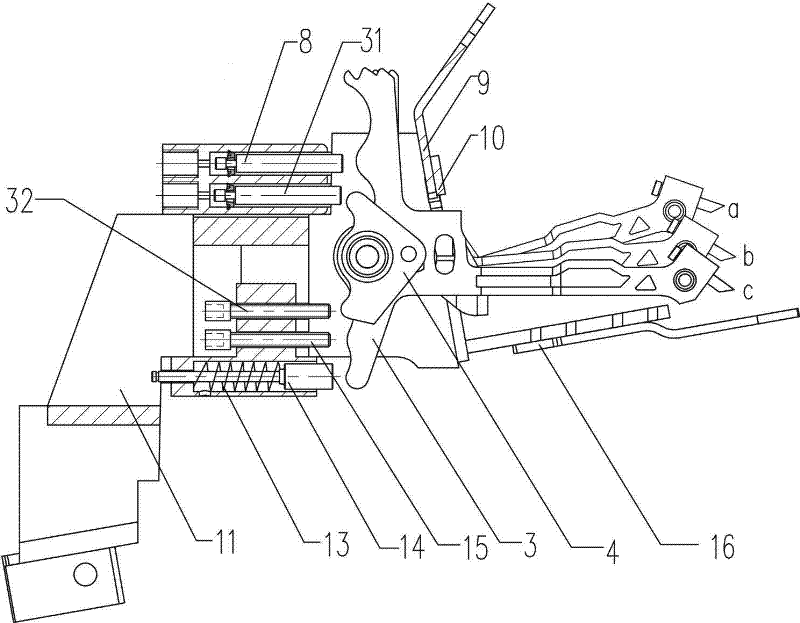

Yarn feeding device of computer silk stockings machine

ActiveCN101994207AReach the function of limit adjustmentPrevent closing and decouplingWeft knittingYarnState of art

The invention discloses a yarn feeding device of a computer silk stockings machine, which comprises a shuttle cylinder body and multiple yarn feeding shuttles, wherein the shuttle cylinder body is provided with multiple first cylinder pistons and push rods with springs; the multiple yarn feeding shuttles are axially connected to the shuttle cylinder body through cylindrical hinge pins; the tail part of each yarn feeding shuttle respectively corresponds to one first cylinder piston and one push rod with the spring, and the cylinder pistons and the push rods with the springs are matched; the shuttle cylinder body is also provided with multiple second cylinder pistons; and the tail part of each yarn feeding shuttle respectively corresponds to one second cylinder piston and is matched with the corresponding second cylinder piston. Compared with the existing technique, the yarn feeding device enhances the use performance of the computer silk stockings machine and the stability in the knitting course, solves the problems of incorrect yarn feeding and low relevant speed in the existing technique, guarantees the knitting quality of the product, enhances the working efficiency and can satisfy the marketization requirements by adopting the technical scheme.

Owner:NINGBO CIXING

Method for callus efficient induction seedling development of stemona sessilifolia

InactiveCN106577291AIncrease the multiplication factorImprove seedling qualityHorticulture methodsPlant tissue cultureShootStemona sessilifolia

The invention discloses a method for callus efficient induction seedling development of stemona sessilifolia. The method comprises the following steps: taking a stemona sessilifolia tender shoot as an explant, and putting the explant into an MS primary induction culture medium to perform induction so as to obtain a sterile test-tube plantlet; putting the test-tube plantlet into an MS callus induction culture medium to perform callus culture; putting an obtained callus into an MS differential culture medium to obtain a large amount of cluster buds; putting the cluster buds into an MS sound seedling culture medium to perform sound seedling culture; and putting obtained robust plants into an MS rooting culture medium to perform rooting culture. A test shows that by adopting the propagation method provided by the invention, the multiplication coefficient of the obtained cluster buds is 40-80 times, the rooting rate of the obtained tissue culture seedlings is 95% or above, and the survival rate of the seedlings transplanted to a seedbed is 90% or above. Therefore, the method disclosed by the invention can make effective use of existing resources to quickly propagate the stemona sessilifolia, solves the problem of industrialized rooting and seedling raising of the stemona sessilifolia, and can fully guarantee a raw material source for medical application development of the stemona sessilifolia.

Owner:GUANGXI UNIV OF CHINESE MEDICINE

Tuckahoe strain expanding culture medium and application thereof

ActiveCN103553830AAccelerated trainingIncrease productionHorticultureFertilizer mixturesBiotechnologySulfate

The invention relates to a tuckahoe strain expanding culture medium and application thereof. The tuckahoe strain expanding culture medium comprises the following raw materials in parts by weight: 30-50 parts of starch, 15-20 parts of wheat bran, 20-40 parts of cassava dregs, 10-20 parts of waste molasses from sugar factories, 5-18 parts of monopotassium phosphate, 1-3 parts of magnesium sulfate, 1-3 parts of ferrous sulfate and 150-200 parts of pine sawdust. The tuckahoe strain expanding culture medium is prepared by the following steps: mixing the raw materials with water to ensure that the water content is 60%-90%, sterilizing the mixture by steam at 110-125 DEG C for 20-30 minutes, and then inoculating a tuckahoe strain. Tuckahoe planted by the tuckahoe strain expanding culture medium provided by the invention is purely nature, superior in quality and high in yield.

Owner:陈永林

Seed introduction, domestication and cultivation breeding method of wild lomatogonium rotatum

ActiveCN110235708ARealize field breeding and plantingImprove germination ratePlant cultivationCultivating equipmentsEndangered medicinal plantWeed

The embodiment of the invention discloses a seed introduction, domestication and cultivation breeding method of wild lomatogonium rotatum and belongs to the technical field of medicinal plant cultivation. The method includes the steps of wild seed collection, seed germination acceleration, soil selection and preparation, sowing, breeding and harvesting. By selecting whole herbal plants of the wild lomatogonium rotatum with slightly hard fruit pods and carrying out specific temperature-changing germination acceleration treatment, the seed germination rate is obviously increased; under combination with a specific cultivation process, the quantity and growth of weeds are effectively controlled, the plant preservation rate reaches 30%, the flowering uniformity reaches 75%, the yield reaches 40 kg / mu, the resource conservation and sustainable use of the scarce and endangered medicinal plant, namely the lomatogonium rotatum, are realized, the bottleneck of a domestication technology is broken through, and market demands are met through industrialized production.

Owner:锡林郭勒盟蒙医医院

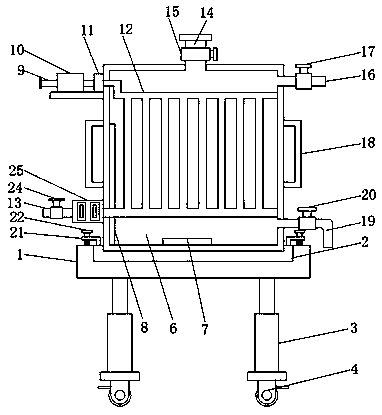

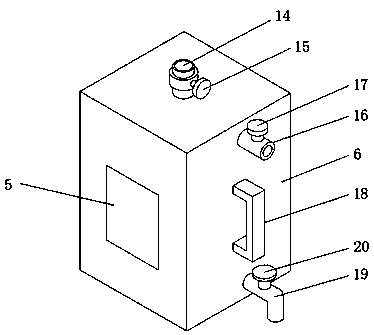

Waste heat recovery device for coating environmental-friendly mechanical equipment

InactiveCN109140409AFirmly connectedMeet the needs of useDispersed particle filtrationBoiler controlMechanical equipmentPollution

The invention discloses a waste heat recovery device for coating environmental-friendly mechanical equipment. The waste heat recovery device comprises a base, a rotating disc and a water tank. The rotating disc is internally embedded in the upper end face of the base, and rotatably connected with the base through a built-in rotating shaft. Vertical telescopic supporting legs are installed at the four corners of the bottom end face of the base correspondingly, the telescopic supporting legs are electric telescopic rods, the water tank is fixed to the rotating disc, and the bottom end of the water tank is internally embedded in the rotating disc. Pushing rods with U-shaped structures are installed on the two symmetrical side faces of the water tank correspondingly, an air inlet pipe is arranged at the top end of the side face where one group of pushing rods are located, and an air outlet pipe is arranged at the near-bottom end of the side face where the group of pushing rods are located,the air inlet pipe extends into the water tank and is connected with a top end interface of a heat conduction pipe inside the water tank, and an extraction fan and an air pump are further connected to the position, on the exterior of the water tank, of the air inlet pipe. According to the waste heat recovery device for the coating environmental-friendly mechanical equipment, connection and fixation with a drying device are convenient, hot air in the drying device is subjected to waste heat recovery advantageously, and pollution of exhaust gas to the environment is reduced.

Owner:海数(青岛)医学科技有限公司

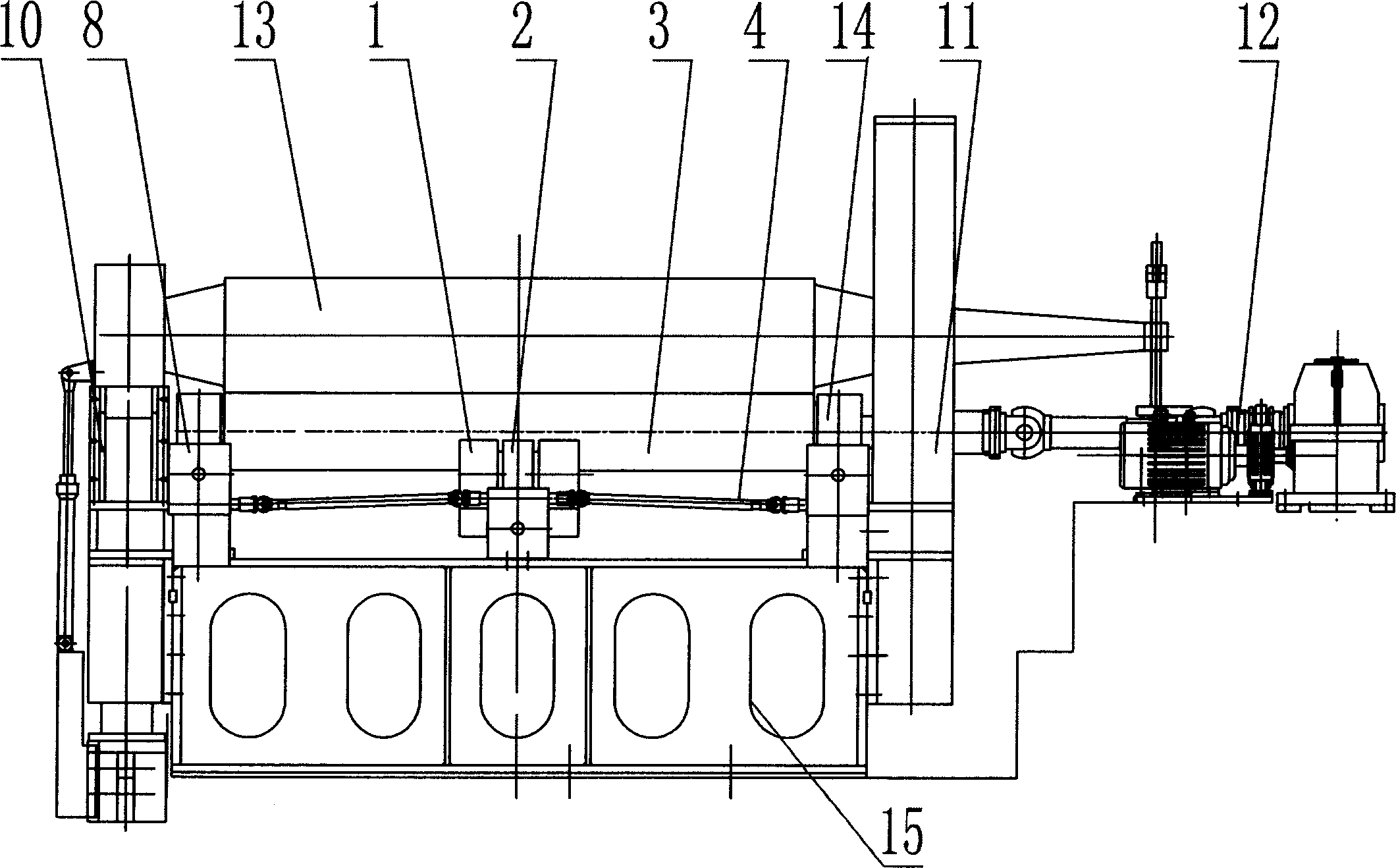

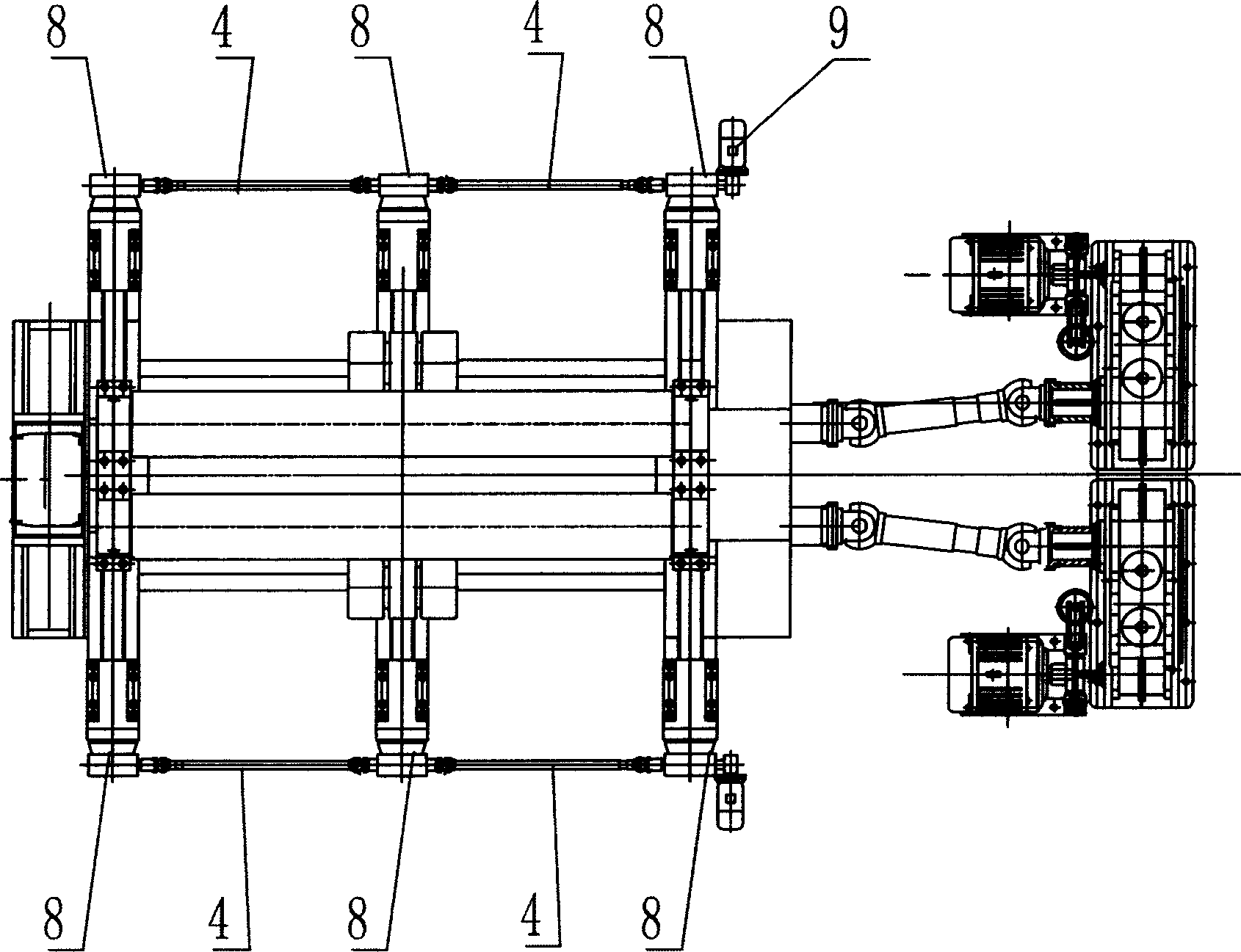

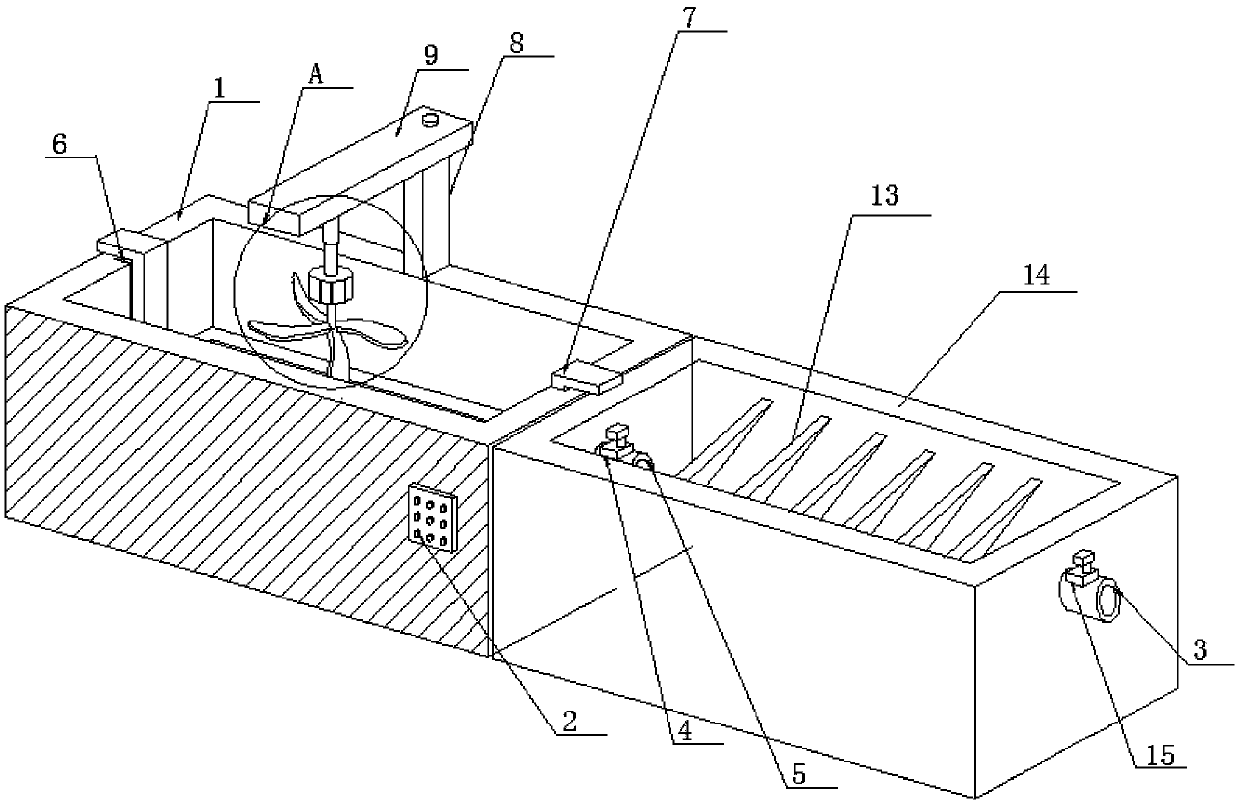

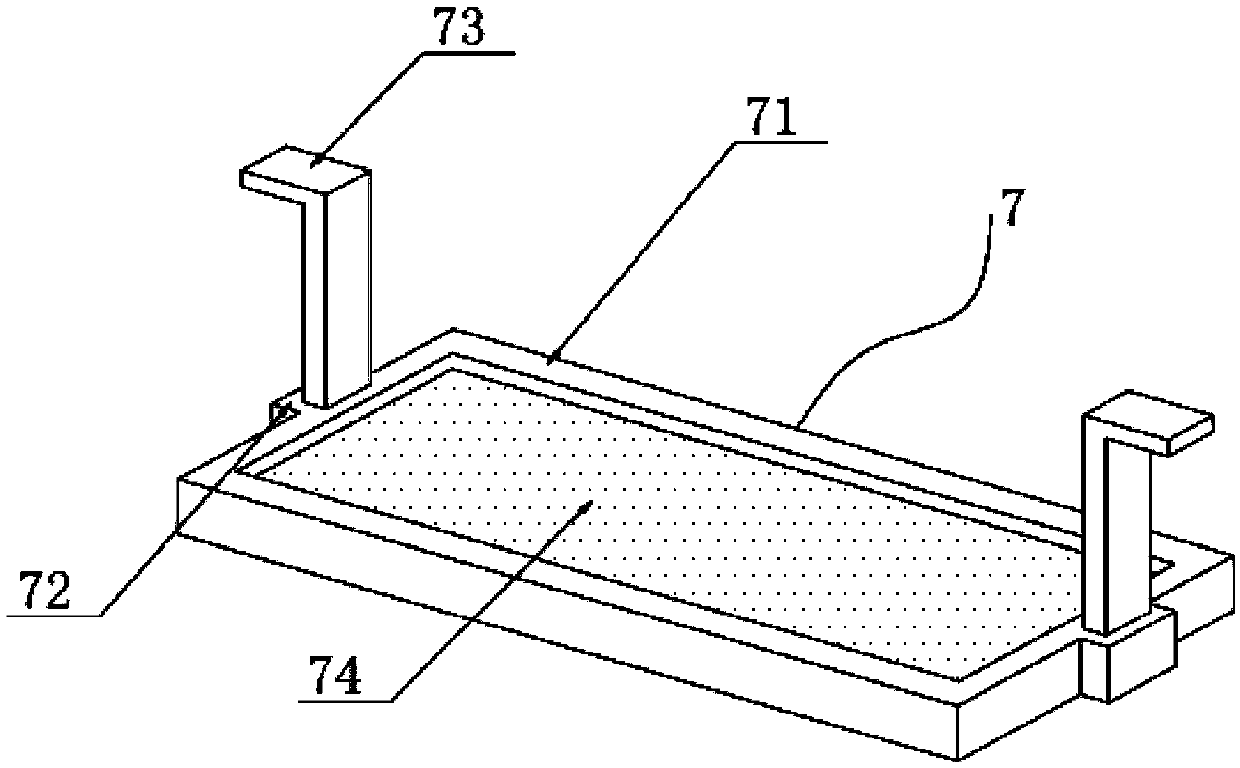

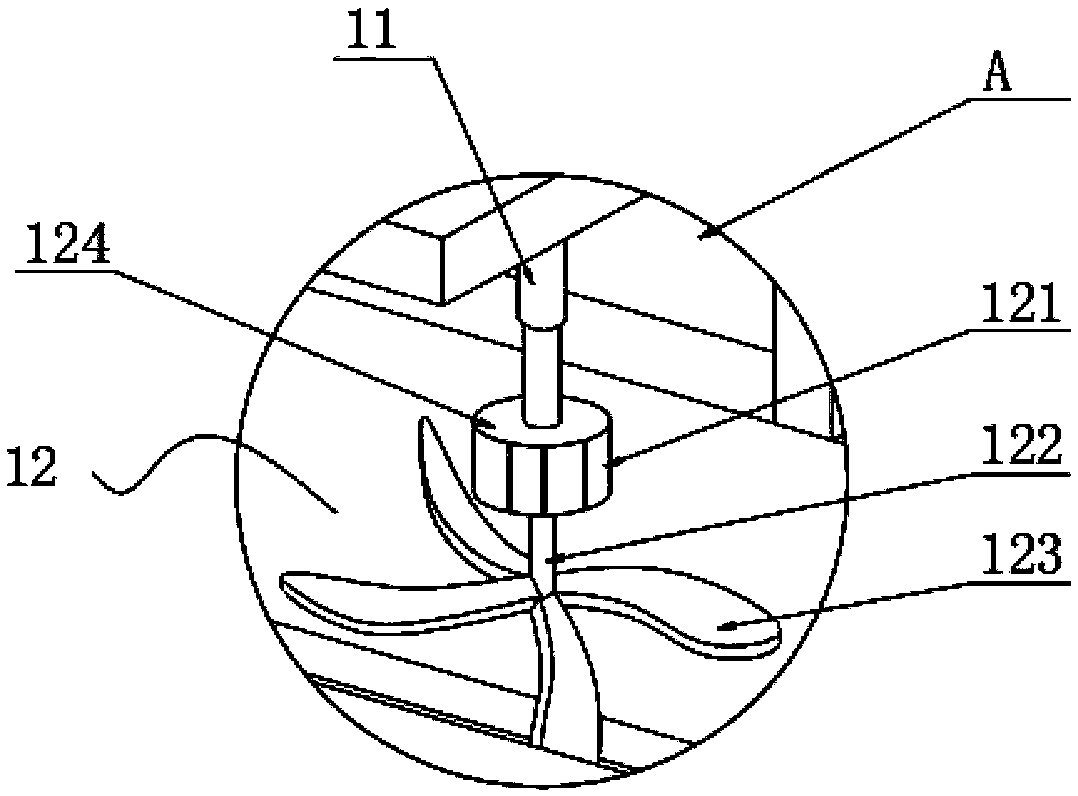

Horizontal downwards regulating three-roller plate bending machine

The horizontal downwards regulating three-roller plate bending machine includes lower roller bearing seat, bearing roller seat, regulators, shift coupling, and motor. Several regulators are mounted symmetrically on two sides of the lower roller bearing seat and the bearing roller seat; the shift coupling is mounted among the regulators; and the lower roller bearing seat and the bearing roller seat have one hole with nut matching the lead screw in the regulators in the lower part and notch or boss in the bottom for mounting on the bottom plate. The regulators are gear worm mechanisms. The present invention has adjustable center distance and support roller and thus has high plate bending quality of both thick steel plate and thin steel plate.

Owner:王建平

High efficiency sedimentation tank for culture farm wastewater treatment

ActiveCN109603292ALarge precipitation spaceImprove sedimentation efficiencyFiltration circuitsThrough transmissionSedimentation

The invention discloses a high efficiency sedimentation tank for culture farm wastewater treatment. According to the invention, a plurality of parallel sedimentation inclined plates are disposed, theareas between two adjacent sedimentation inclined plates form sedimentation cavities, and each sedimentation inclined plate is provided with a connecting hole communicated with the sedimentation cavities, and the heights of the connecting holes on the sedimentation inclined plates close to a secondary water inlet end are higher than those of the connecting holes on the sedimentation inclined plates far from the secondary water inlet end, therefore sediments in all the sedimentation cavities can be settled level by level, and the content of sediments in each sedimentation cavity tends to be consistent, moreover, along with settling, the sediments in subsequent sedimentation cavities decrease, and the sedimentation space is large, thus facilitating thorough settling, and a cleaning componentis arranged, when a filtering component is taken out of a sliding chute, through transmission of a connecting block, impurities at the bottom of the sedimentation tank can be cleaned, thus being convenient for separation of the impurities from the bottom of the sedimentation tank.

Owner:ANHUI SCI & TECH UNIV

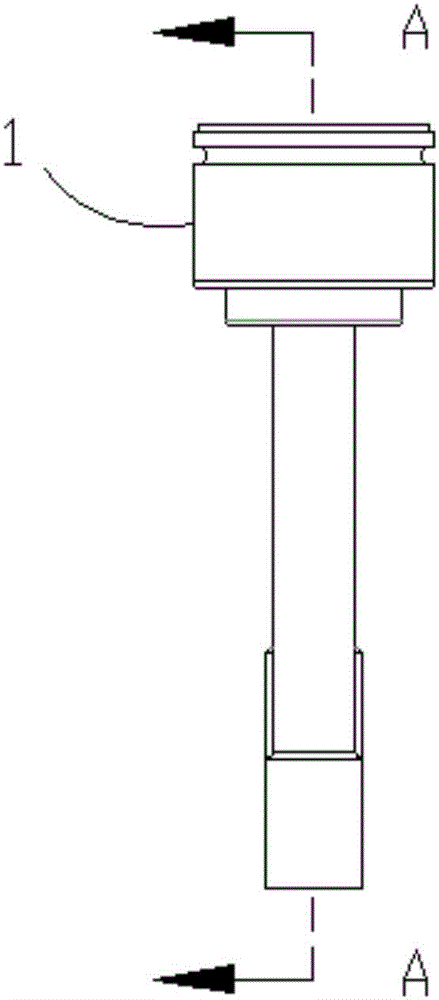

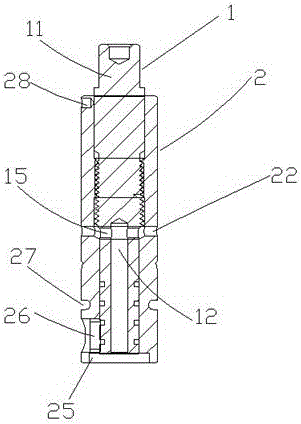

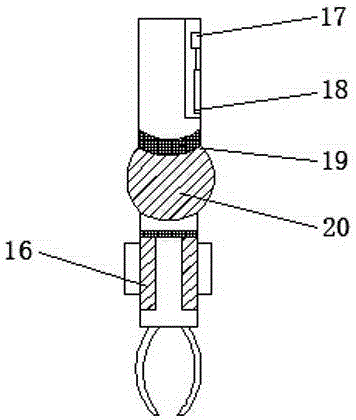

Valve rod assembly on electronic expansion valve

PendingCN106439211AEliminate axial stressImprove sealingValve arrangementsEfficient regulation technologiesAxial pressureElectronic expansion valve

The invention discloses a valve rod assembly on an electronic expansion valve. The valve rod assembly comprises a valve rod and a bearing pedestal. The valve rod is arranged in a through hole of the bearing pedestal. The valve rod assembly is characterized by comprising a rod body, an inner axial hole column is formed at the middle and lower end of the rod body, a first transverse hole column communicated with the inner axial hole column is formed on the outer wall of the bottom of the inner axial hole column, and a second transverse shaft hole communicated with the through hole is formed in the middle of the wall body of the bearing pedestal. The valve rod assembly can eliminate axial pressure born by the valve rod, moreover, the good sealing effect is achieved, and meanwhile the cost is reduced to meet the market requirements.

Owner:ZHUJI YIBA ELECTRONICS VALVE

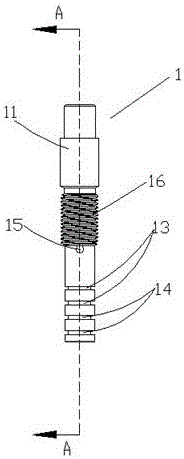

Single split mold orifice para-position positioning and material distributing system and use method

ActiveCN111231085ASatisfy the willRich and diverse color zone pattern effectFeeding arrangmentsNumerical controlEngineering

The invention provides a single split mold orifice para-position positioning and material distributing system and a use method, and belongs to the field of building ceramic tiles. The single split mold orifice para-position positioning and material distributing system comprises a prefabricated raw material transferring and supplying device, a para-position material distributing device, a flowguidegrille and a conveying carrier. The prefabricated raw material transferring and supplying device is sequentially provided with multiple color zone stations in the conveying direction of the conveyingcarrier. The para-position material distributing device is arranged below the prefabricated raw material transferring and supplying device, multiple discharging holes for distributing materials are formed in the bottom of the para-position material distributing device, and a switch is arranged on each discharging hole. The flowguide grille is located below the discharging holes, a guide-in mold orifice is formed in the top of the flowguide grille, and a guide-out mold orifice is formed in the bottom of the flowguide grille. The conveying carrier is located below the para-position material distributing device, and the flowguide grille is arranged on the surface of the conveying carrier. According to the system, a manufactured blank is clear in whole pattern border, the distributing amountis sufficient, the system is automatic, high in intelligent numerical control degree and high in efficiency, and the production efficiency is greatly improved.

Owner:GUANGDONG SUMMIT CERAMIC CO LTD +2

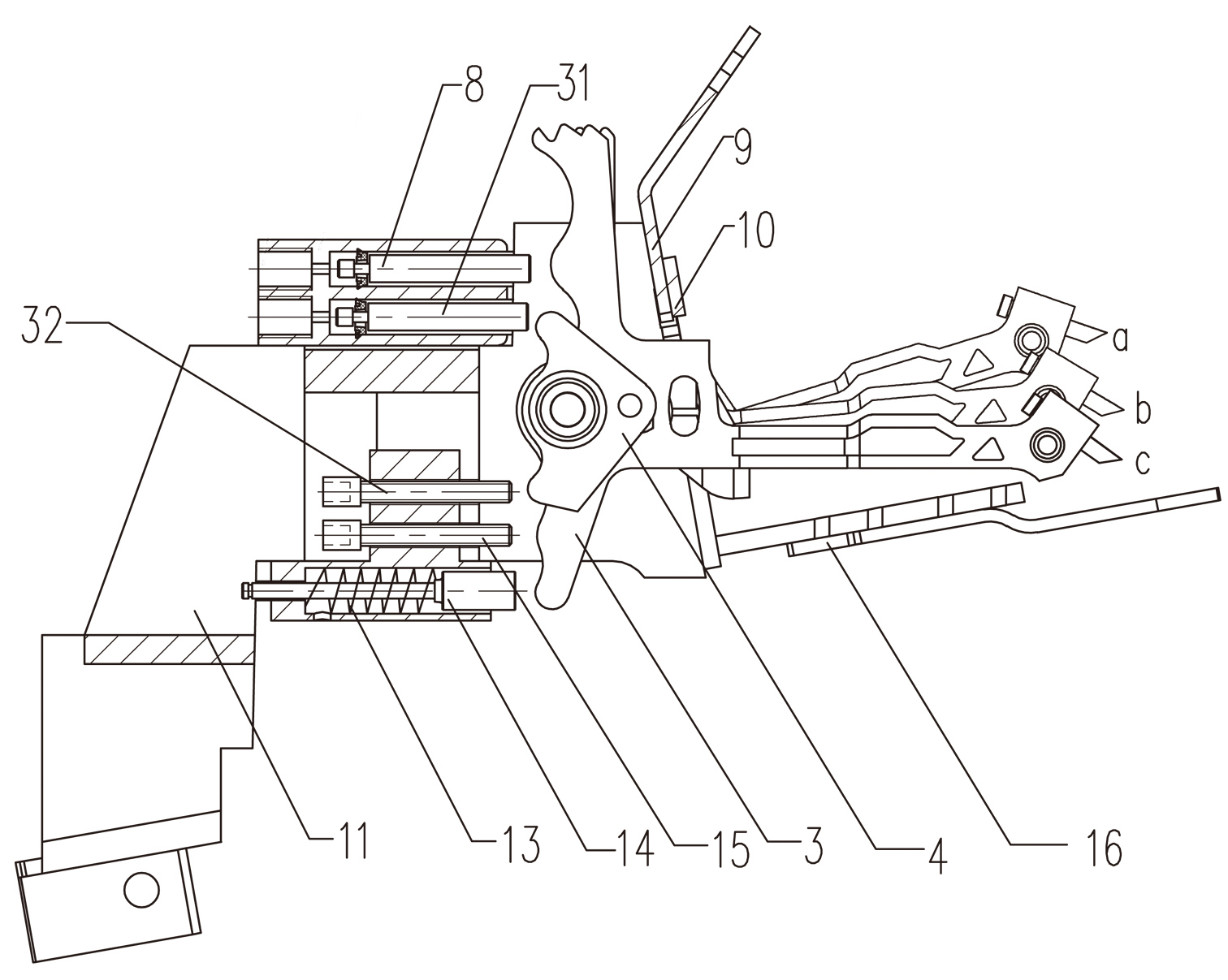

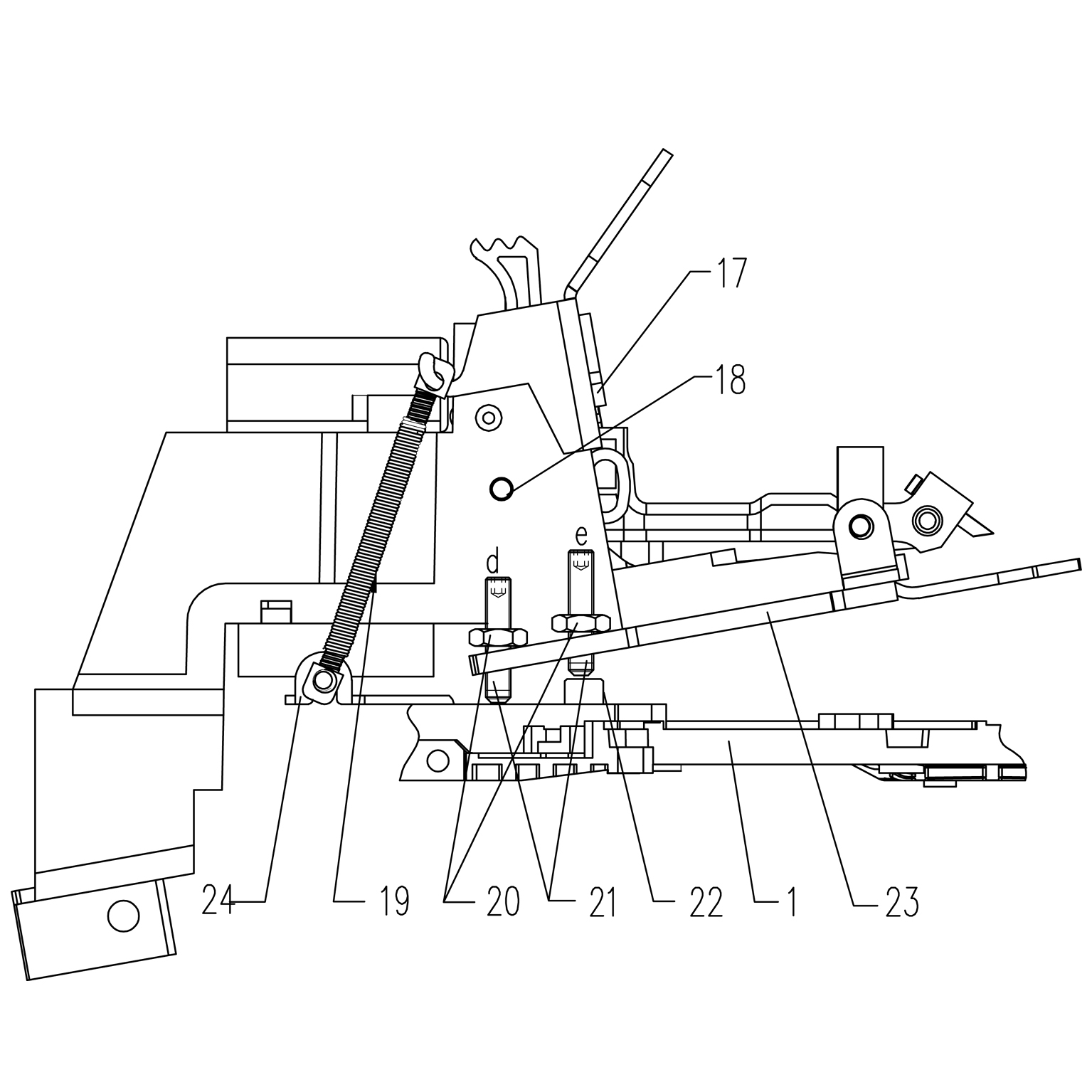

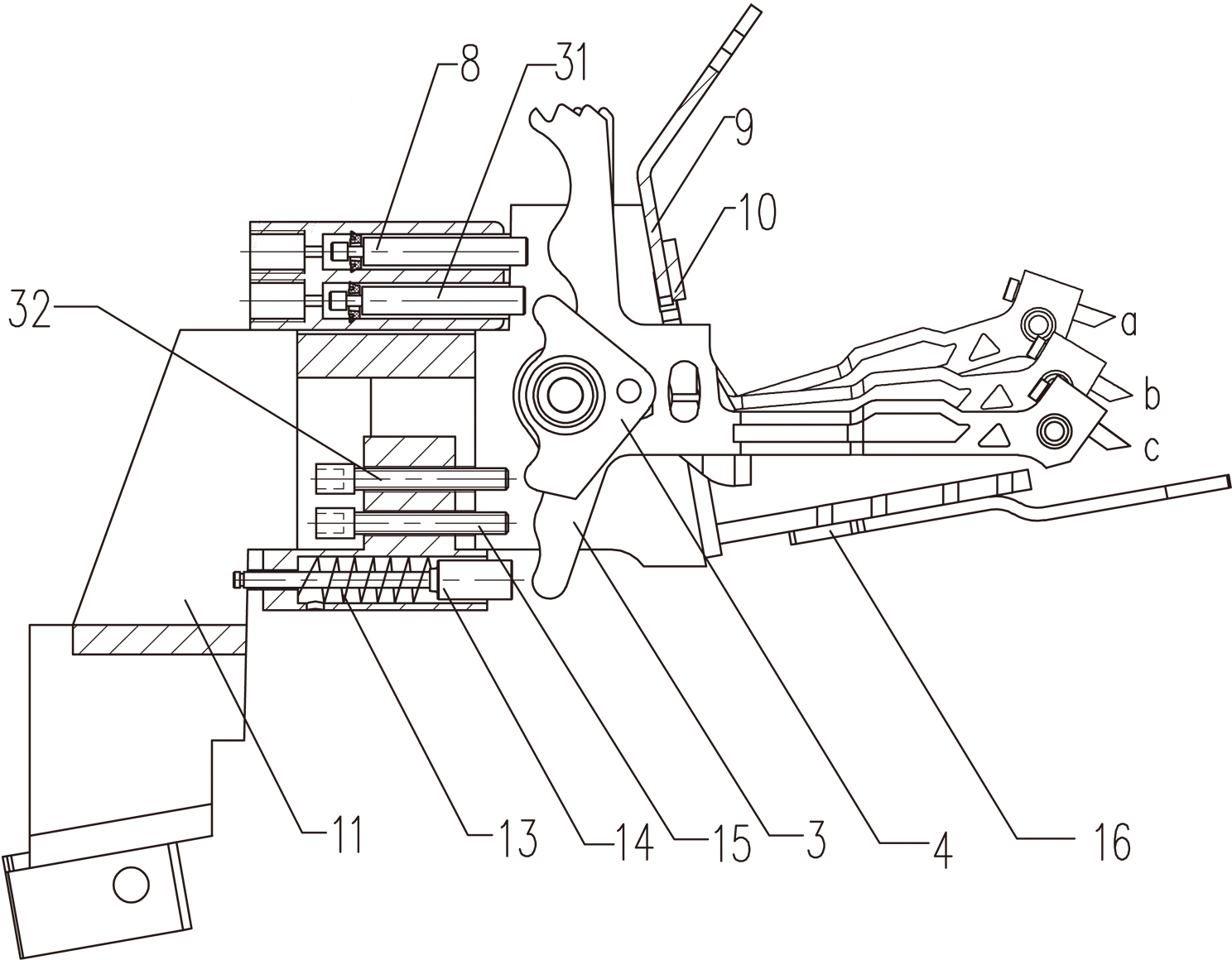

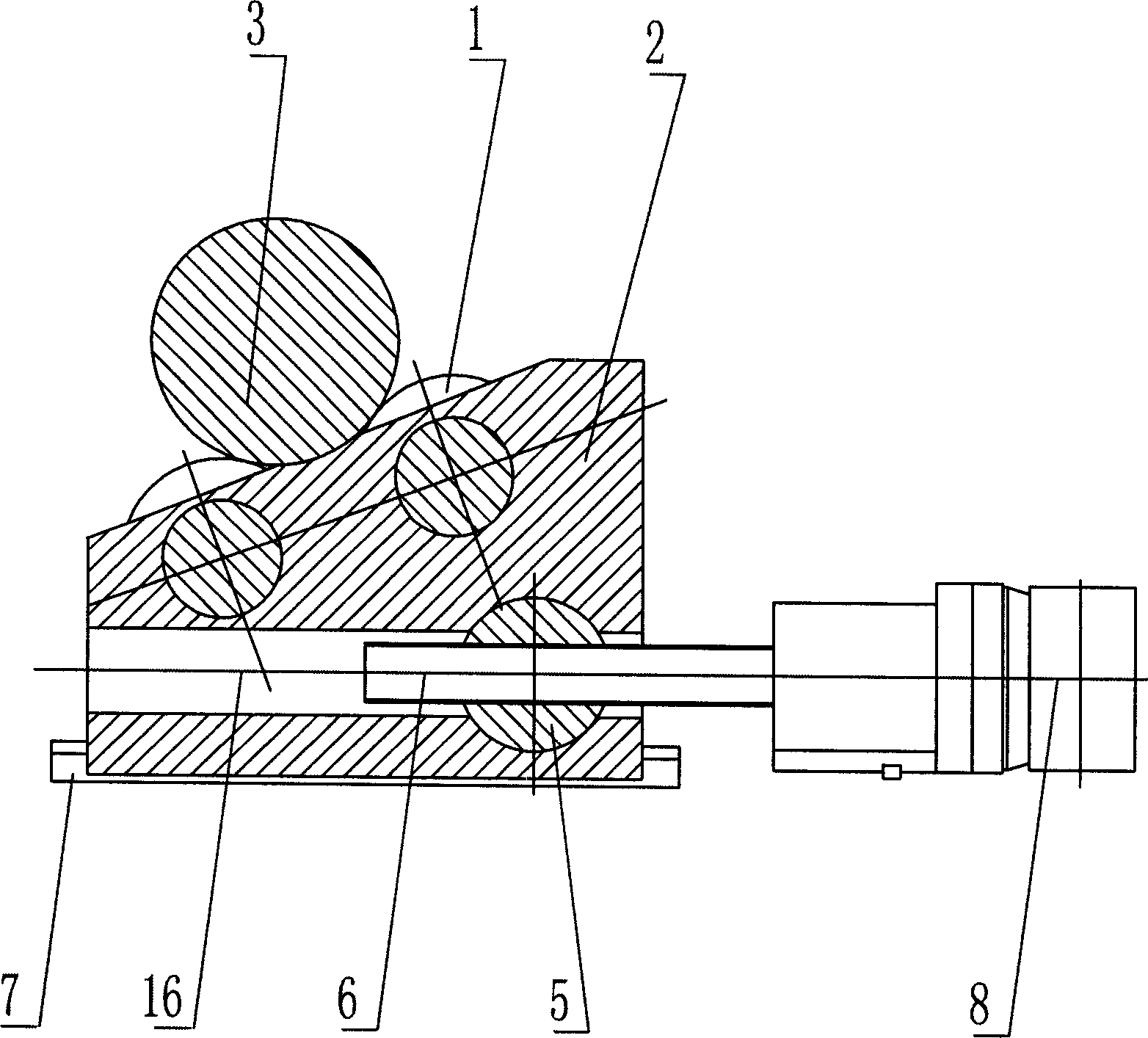

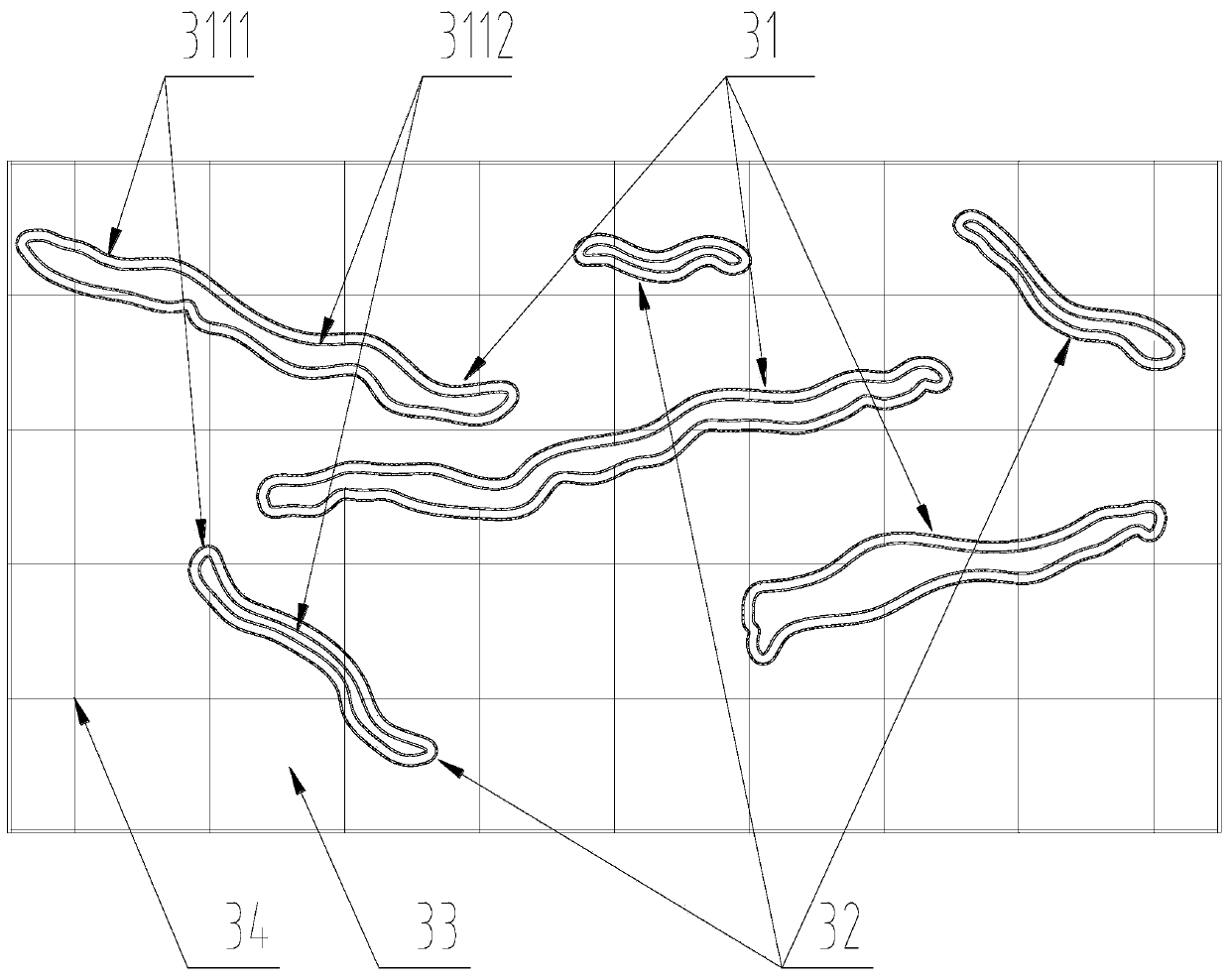

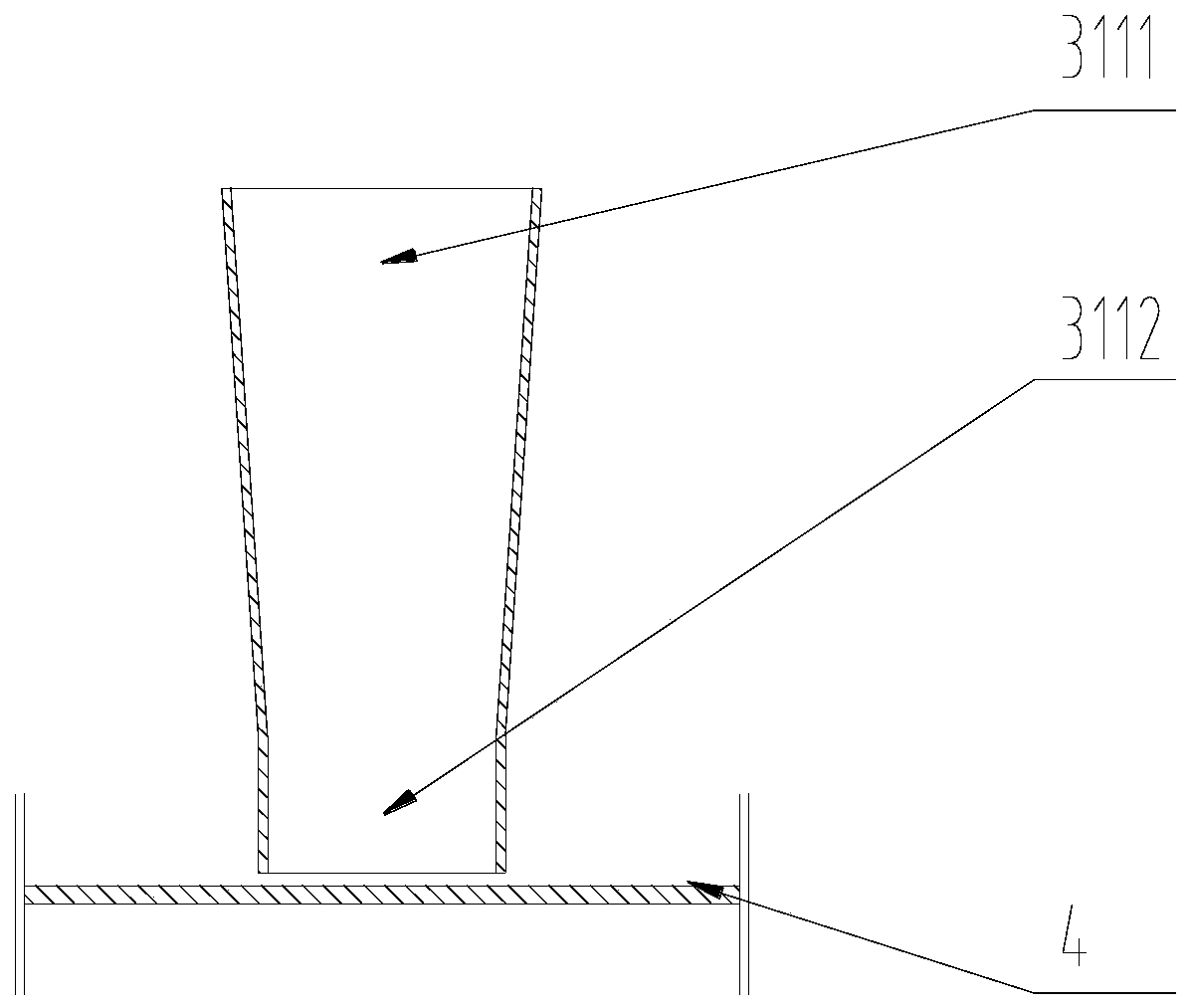

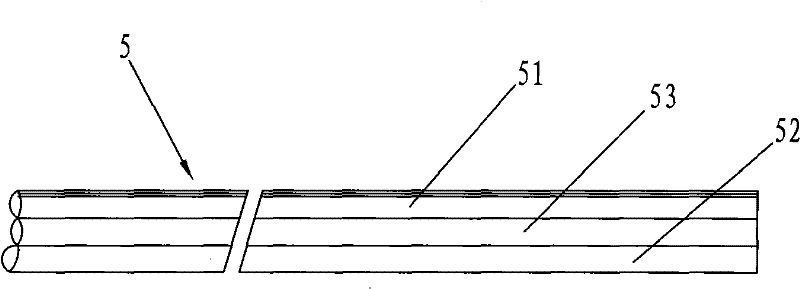

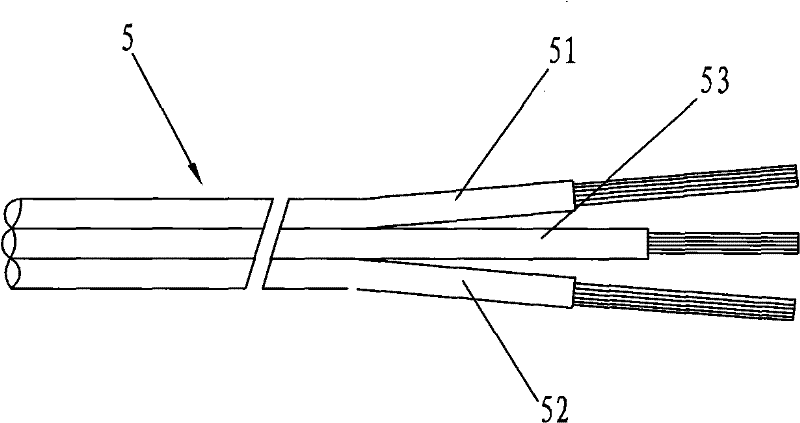

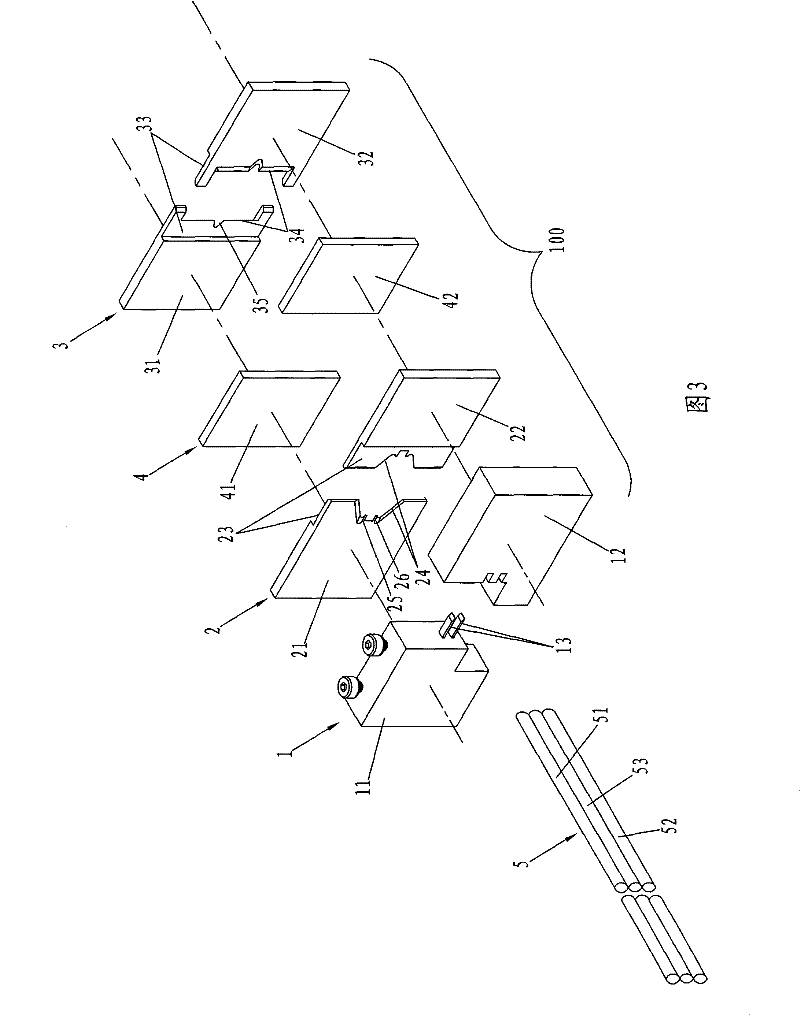

Cutting tool assembly for peeling three bundle of parallel core wires and peeling machine using the same

InactiveCN101431223BQuick peelEasy to removeLine/current collector detailsApparatus for removing/armouring cablesEngineeringToolbox

The invention relates to a three-bundle parallel core wire stripping toolbox and a stripping machine using the toolbox. The toolbox first branches off three bundles of parallel core wires by a branch cutting die, then precutting process is carried out on skins of the core wires at two sides and in the middle by a first cutting die and a second cutting die respectively, and a partition board arranged between the first cutting die and the second cutting die can ensured that a certain distance exists between the cutting positions of the core wires at two side parts and the core wire in the middle, so as to meet market requirements. The stripping machine precuts the skin at the end parts of the core wires by the toolbox driven by a first cylinder, and then drives the toolbox and the first cylinder to move along the core wire extending direction by a second cylinder, so that the toolbox can move to strip the precut skins under the condition that the core wires keep motionless, therefore, the manual work manner in the prior art can be replaced, the skins at the end parts of the core wires can be stripped off rapidly and conveniently, and the invention is suitable for mass production is high, thus improving the stripping efficiency.

Owner:LINOYA ELECTRONIC TECHNOLOGY CO LTD

Micro-water dyeing method suitable for wool

The invention relates to a micro-water dyeing method suitable for wool. The micro-water dyeing method comprises the following steps that a, products to be dyed are prepared; b, a dedicated dyeing system is configured, specifically, reactive dyes and metered water only used for dissolving the reactive dyes are uniformly stirred, and poor solvents of the reactive dyes are added to prepare the dedicated dyeing system; c, dyeing is carried out; d, soaping is carried out; e, dehydrating is carried out; and f, drying is carried out, and dyeing products are obtained. Compared with a traditional woolreactive dyeing method, the dyeing method does not require any accelerating salt, with the help of non-aqueous media with low surface tension, the reactive dyes can be rapidly dyed to the surfaces ofwool fibers, the reactive dyes hardly hydrolyze without an alkaline agent, and the fixation rate of the reactive dyes is greatly improved. According to the micro-water dyeing method suitable for the wool, the use ratio of the reactive dyes for wool dyeing is effectively improved, the dyed wool is not required to be specifically processed, and the wet rubbing fastness meets the requirements in themarket.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD +1

Yarn feeding device of computer silk stockings machine

ActiveCN101994207BReach the function of limit adjustmentPrevent closing and decouplingWeft knittingYarnEngineering

The invention discloses a yarn feeding device of a computer silk stockings machine, which comprises a shuttle cylinder body and multiple yarn feeding shuttles, wherein the shuttle cylinder body is provided with multiple first cylinder pistons and push rods with springs; the multiple yarn feeding shuttles are axially connected to the shuttle cylinder body through cylindrical hinge pins; the tail part of each yarn feeding shuttle respectively corresponds to one first cylinder piston and one push rod with the spring, and the cylinder pistons and the push rods with the springs are matched; the shuttle cylinder body is also provided with multiple second cylinder pistons; and the tail part of each yarn feeding shuttle respectively corresponds to one second cylinder piston and is matched with the corresponding second cylinder piston. Compared with the existing technique, the yarn feeding device enhances the use performance of the computer silk stockings machine and the stability in the knitting course, solves the problems of incorrect yarn feeding and low relevant speed in the existing technique, guarantees the knitting quality of the product, enhances the working efficiency and can satisfy the marketization requirements by adopting the technical scheme.

Owner:NINGBO CIXING

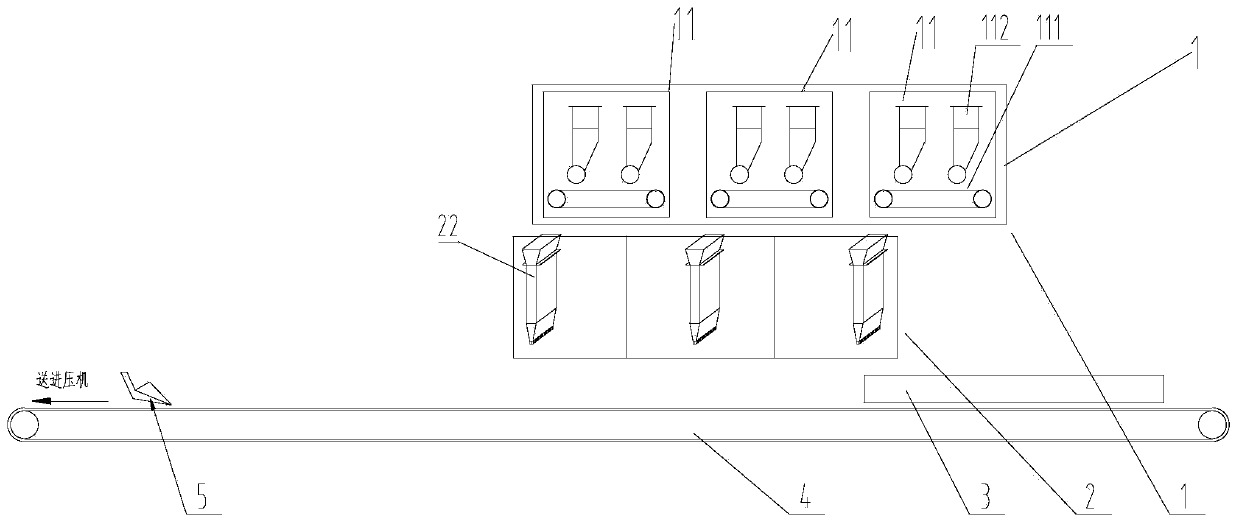

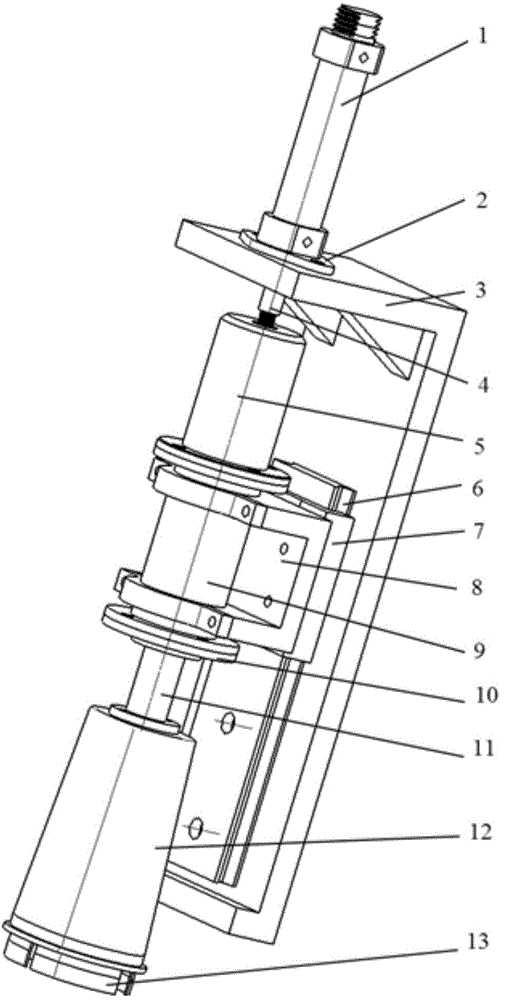

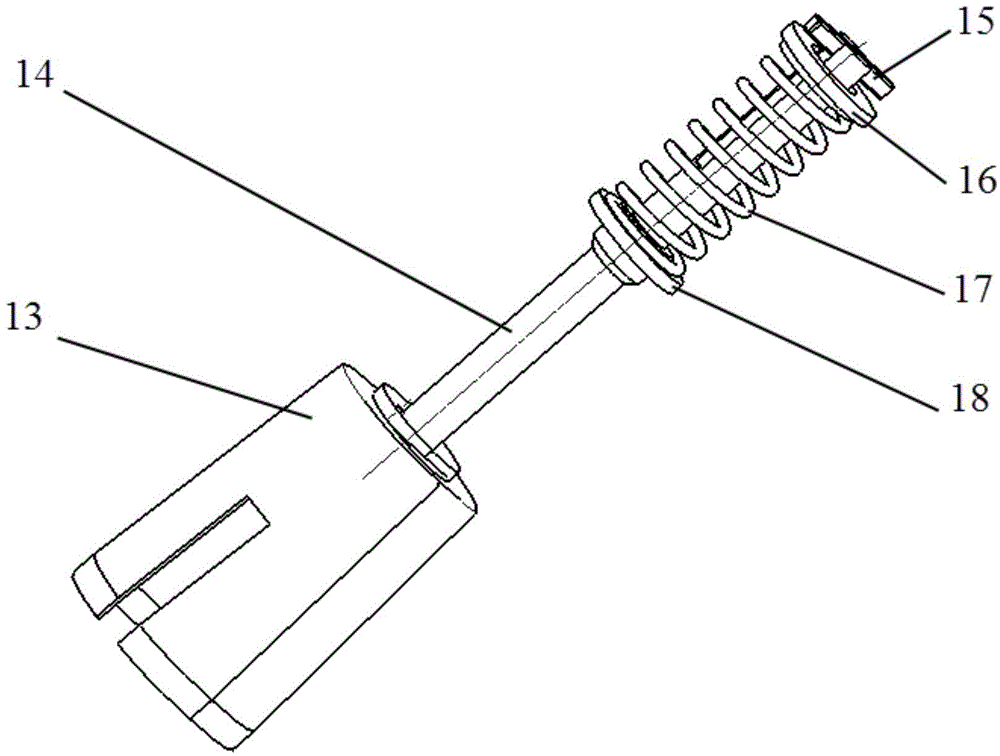

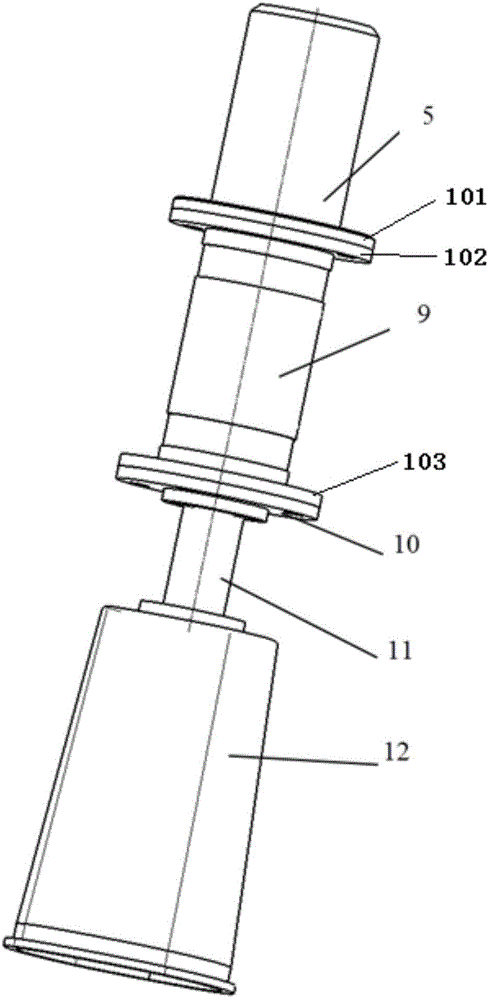

Automatic assembly device of flexible component

The invention relates to an automatic assembly device of a flexible component used for achieving the guiding and compressing assembly technology of the flexible component at the same time. The automatic assembly device comprises an air cylinder, a supporting component, a guiding component and a compressing component, wherein the air cylinder is fixed onto the supporting component through a flange, the supporting component is connected with the compressing component in a sliding mode, the guiding component is arranged inside the compressing component, and the compressing component is connected with an air cylinder piston rod of the air cylinder. Compared with the prior art, the automatic assembly device of the flexible component has the advantages of being simple and compact in structure, high in work efficiency and wide in application range.

Owner:TONGJI UNIV

Probiotic composition and preparation thereof

ActiveCN101897729BAvoid infectionImprove proliferative abilityOrganic active ingredientsBacteriaBiotechnologyProbiotic bacterium

Owner:天津金士力健康用品有限公司

Honey paste processing technology

The invention belongs to the technical field of honey processing and provides a honey paste processing technology. The technology comprises (1) preparing a liquid seed crystal, (2) preparing a solid seed crystal, (3) preparing a raw material seed crystal, (4), carrying out mixing, (5) carrying out pulsed laser processing and (6) carrying out vacuuming. Through use of the raw material seed crystalsprepared from the liquid and solid seed crystals, adjustment of parameters such as moisture content, a crystallization temperature and a mass ratio in the preparation of liquid and solid seed crystals and use of pulsed laser and photothermal conversion, the solution close to a light focus is instantaneously evaporated and the honey is concentrated. Simultaneously, a shock wave is generated to partially shake the honey liquid and promote the formation of a crystallization nucleus, thereby improving the crystal grain uniformity and the delicateness and optimizing the honey quality. The honey paste has a thick and pure taste and satisfies the market demands.

Owner:MINGGUANG HAOHAO BEES

Quality detection method of Shouhui bowel-relaxing capsule

ActiveCN109507356AQuality assuranceComprehensive evaluationComponent separationAtractylenolide IIIAtractylenolide I

The invention discloses a quality detection method of a Shouhui bowel-relaxing capsule and belongs to the field of analysis of traditional Chinese medicinal preparations. The quality detection methodadopts a thin-layer chromatography to identify bighead atractylodes rhizome in the capsule and simultaneously adopts an HPLC to determine the contents of atractylenolide I, atractylenolide II and atractylenolide III in the capsule. The quality detection method disclosed by the invention is stable and reliable, strong in specificity, good in reproducibility and capable of fully and effectively controlling the quality of the euphorbia pulcherrima bowel-relaxing capsule, ensuring the safety and the effectiveness of clinical medication and better meeting the needs of patients and the market.

Owner:LUNAN PHARMA GROUP CORPORATION

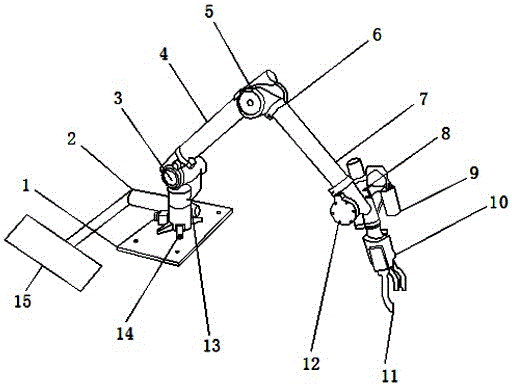

Remote mechanical arm based on internet of things

InactiveCN106426113APrevent rustExtended service lifeProgramme-controlled manipulatorControl engineeringThe Internet

The invention discloses a remote mechanical arm based on the internet of things. The remote mechanical arm comprises a fixing base, a main drive rod, a mechanical arm body, a mechanical arm shaft and a table post. The table post is installed on the fixing base, and reinforcing fixing pieces are arranged on the surface of the table post. The table post is connected with a signal executer through an intelligent controller connecting port. A main rotary shaft is installed on the upper portion of the table post, and the main drive rod is installed on the upper portion of the main rotary shaft. The main drive rod is connected with the mechanical arm body through a connecting rotary shaft. An end effector is arranged on the lower portion of the mechanical arm body, and a mechanical arm shaft is installed on the left side of the end effector. A mechanical arm shaft chamber is installed below the mechanical arm shaft. Operating claws are arranged on the lower portion of the mechanical arm shaft chamber. According to the remote mechanical arm based on the internet of things, since a camera is arranged on the mechanical arm, the working condition of the mechanical arm can be clearly known from a display screen; and then remote operation is conducted, operation is easier, and the functionality of the remote mechanical arm is improved.

Owner:NANLING ZINGIBER MIOGA ROSE IND ASSOC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com