Automatic assembly device of flexible component

An automatic assembly device, a technology of flexible parts, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem that the synchronization of the two motions of guiding and pressing depends on the control system, the production cost and space layout are large, and the manual assembly work Low efficiency and other problems, to achieve the effect of ingenious mechanism and device structure, avoiding manual assembly and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

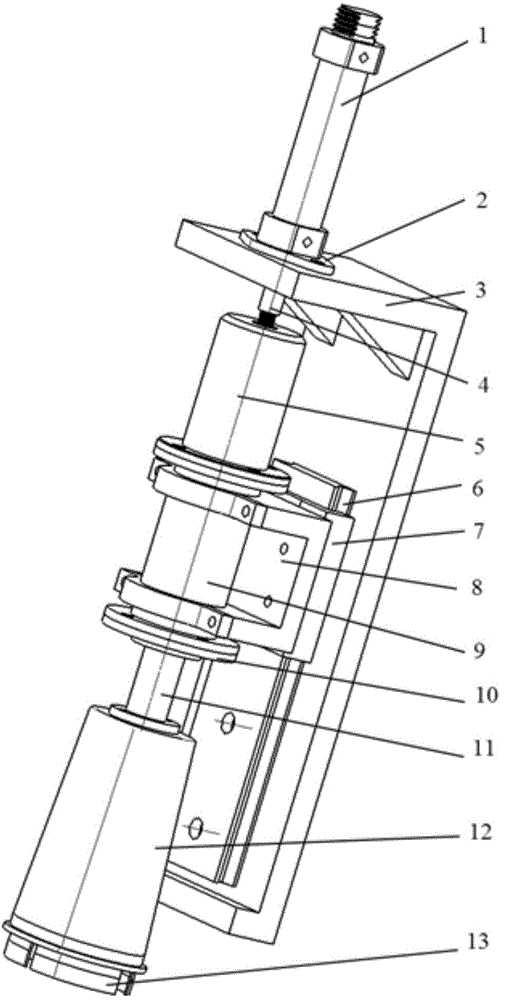

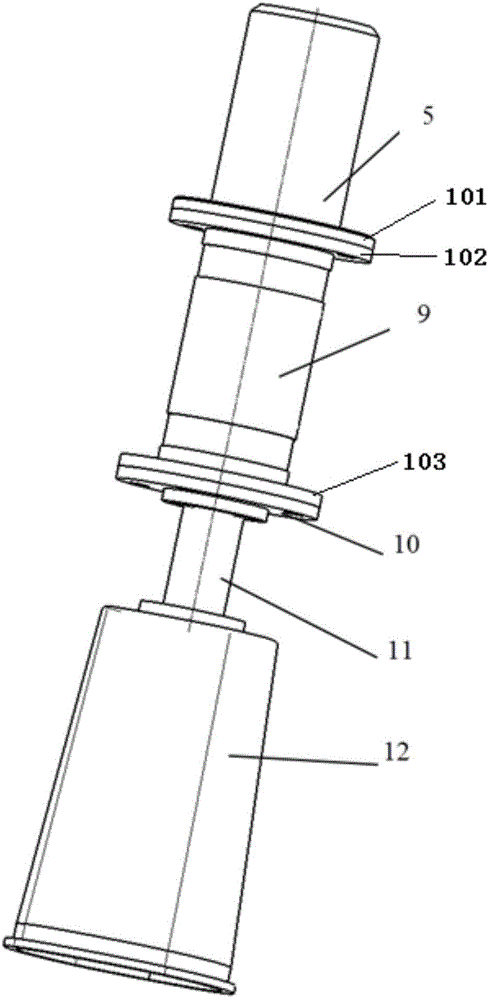

[0027] Such as figure 1 and 7 As shown, an automatic assembly device for flexible parts is used to realize the guidance and compression of the elastic sealing ring at the same time, and install the elastic sealing ring on the valve base. The device includes a cylinder 1, a supporting component, a guiding component and a compressing component , the cylinder 1 is fixed on the support assembly through the flange 2, the support assembly is slidingly connected with the compression assembly, the compression assembly is provided with a guide assembly, the compression assembly is connected with the cylinder piston rod 4 of the cylinder 1, and the support assembly includes a support frame 3 And the guide rail 6 arranged on the support frame 3, the support frame 3 is L-shaped, and the guide rail 6 is connected with the support frame 3 by bolts.

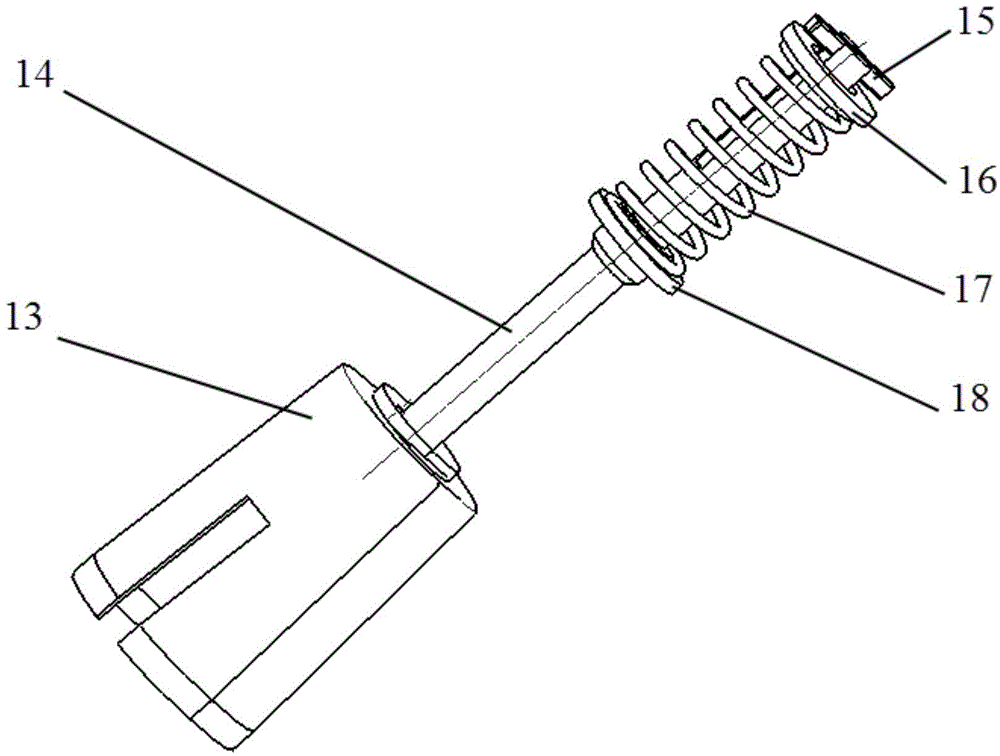

[0028] Such as image 3 As shown, the compression assembly includes a connecting plate 8, a slider 7, and an upper cover 5, a large connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com