Single-component heat-curing liquid silicone rubber and preparation method thereof

A liquid silicone rubber, heating and curing technology, applied in the field of liquid silicone rubber, can solve the problems of vulcanization, large thixotropy, and short storage time at room temperature, and achieve excellent temperature resistance, good thermal conductivity, and long-term stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

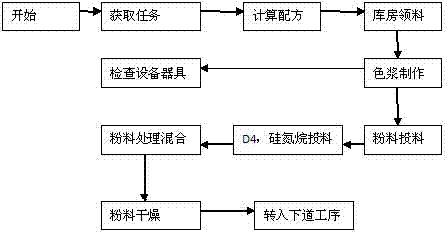

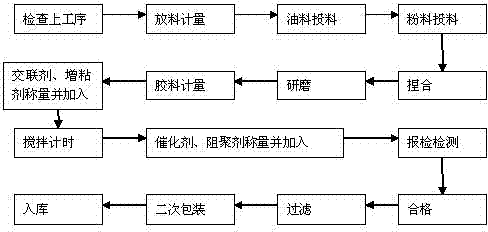

Method used

Image

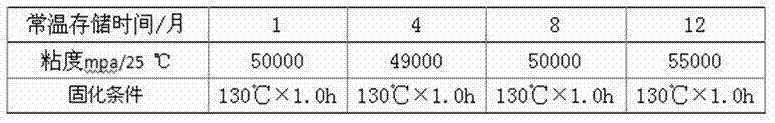

Examples

Embodiment 1

[0044] Add 100 parts of vinyl polysiloxane, 50 parts of pretreated alumina, 50 parts of aluminum nitride, 30 parts of aluminum hydroxide and 10 parts of fumed silica into the kneader, stir evenly, and heat up to 130°C , after vacuum stirring for 2 hours, take it out, and grind it once on a three-roller machine to obtain a base compound with evenly dispersed fillers.

[0045] Take 100 parts of the base rubber and stir in a planetary kettle, add 3 parts of hydropolysiloxane obtained according to the mass of the added base rubber, 0.5 parts of vinyltriethoxysilane as a tackifier, and 0.005 parts of butyne Alcohol and 0.005 cyclohexynol, after stirring evenly, add 0.05 parts of platinum complex catalyst, and stir for 2 hours. Filtered packaging can be formulated into one-component heat-cured silicone rubber.

[0046] Among them, the pretreatment of fillers (including alumina, aluminum nitride or aluminum hydroxide)

[0047] Add 100 parts (parts by mass, the same below) of alu...

Embodiment 2

[0049] Add 100 parts of vinyl polysiloxane, 100 parts of pretreated aluminum oxide, 80 parts of aluminum nitride, 50 parts of aluminum hydroxide and 20 parts of fumed silica into the kneader, stir evenly, and heat up to 160°C After evacuating and stirring for 6 hours, take it out, and grind it twice on a three-roller machine to obtain a base compound with evenly dispersed fillers.

[0050] Take 100 parts of the base rubber and stir in a planetary kettle, add 6 parts of hydropolysiloxane obtained according to the mass of the added base rubber, 2 parts of vinyltrimethoxysilane tackifier, 0.01 part of butynol and 0.01 part of cyclohexynol, after stirring evenly, add 0.2 part of platinum complex catalyst, and stir for 4 hours. Filtered packaging can be formulated into one-component heat-cured silicone rubber.

[0051] Pretreatment of fillers including alumina, aluminum nitride or aluminum hydroxide

[0052] Add 100 parts (parts by mass, the same below) of alumina, aluminum nitr...

Embodiment 3

[0054] Add 100 parts of vinyl polysiloxane, 80 parts of pretreated aluminum oxide, 70 parts of aluminum nitride, 40 parts of aluminum hydroxide and 15 parts of fumed silica into the kneader, stir evenly, and heat up to 150°C , after evacuating and stirring for 5 hours, take it out, and grind it once on a three-roller machine to obtain a base compound with evenly dispersed fillers.

[0055] Take 100 parts of the base rubber and stir in the planetary kettle, add 5 parts of hydropolysiloxane obtained according to the mass of the added base rubber, γ-(2,3-epoxypropoxy)propyltrimethoxy 1.5 parts of silane tackifier, 0.008 part of butynol and 0.007 part of cyclohexynol, after stirring evenly, add 0.1 part of platinum complex catalyst, and stir for 3 hours. Filtered packaging can be formulated into one-component heat-cured silicone rubber.

[0056] Pretreatment of fillers including alumina, aluminum nitride or aluminum hydroxide

[0057] Add 100 parts (parts by mass, the same belo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com