Valve rod assembly on electronic expansion valve

A technology of electronic expansion valve and valve stem, which is applied in the direction of refrigeration components, valve devices, engine components, etc., can solve the problems of high cost, achieve the effects of reducing cost, preventing the increase of gas leakage, and eliminating axial pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

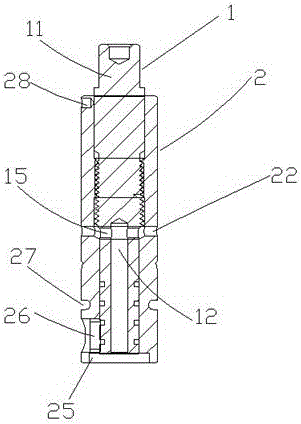

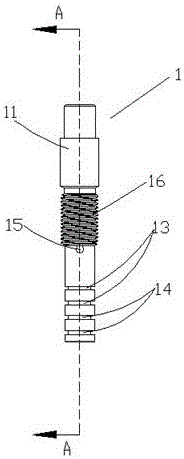

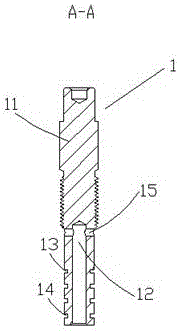

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, a valve stem assembly on an electronic expansion valve includes a valve stem 1 and a bearing seat 2. The threaded section 16, the bearing seat 2 includes a seat body 23, a through hole 21 is formed in the seat body 23, the through hole 21 matches the valve stem 1, and is formed in the middle of the inner wall of the through hole 21 The internal thread section 24 matched with the external thread section 16 is matched with the external thread section 16 through the internal thread section 24 during installation, and the thread rotation between the two can be adjusted to a certain extent. By measuring the uppermost end of the bearing seat and the top of the valve stem The distance between them is used to determine the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com