Single split mold orifice para-position positioning and material distributing system and use method

A cloth system and die opening technology, applied in the direction of supply devices, manufacturing tools, etc., can solve the problems of inability to form precise positioning cloth patterns, unreachable raw material shapes, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

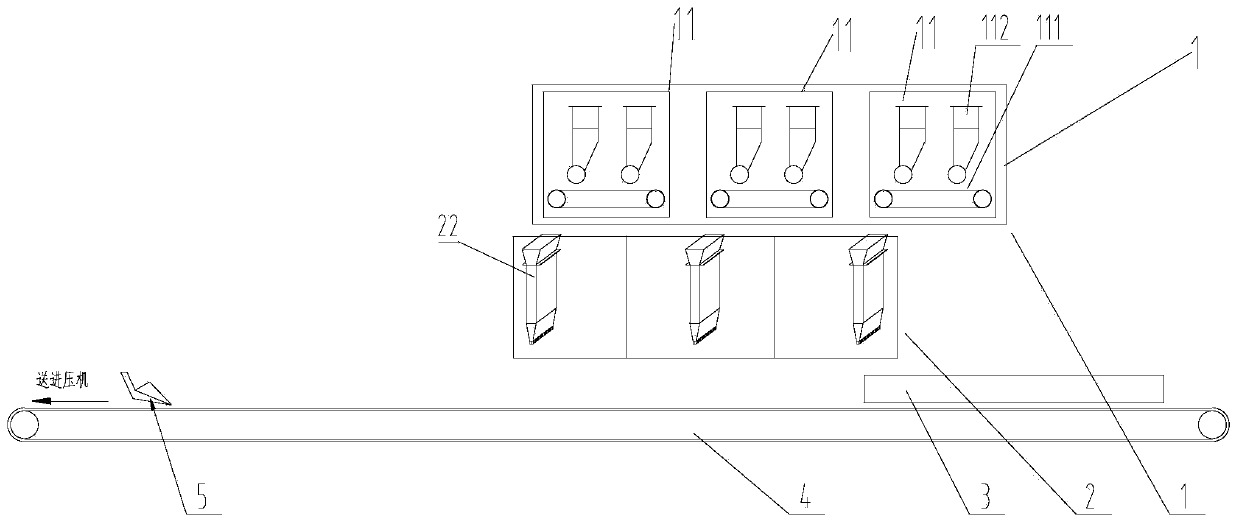

[0110] Such as Figure 1-Figure 4 As shown, a combined die opening alignment positioning distribution system includes a device 1 for transferring and supplying prefabricated raw materials, an alignment distribution device 2 , a diversion grid 3 and a feeding carrier 4 .

[0111] The transfer supply prefabricated raw material device 1 is provided with a plurality of color zone stations 11 in sequence along the conveying direction of the feed carrier 4; further, each of the color zone stations 11 is provided with a loading roller The bucket 112 and the feeding carrier 1114, the number of the loading roller bucket 112 in each color zone station 11 is 1 or more, and the loading roller bucket 112 is along the feeding The lengthwise direction of the carriers 4 is arranged side by side, and the loading and feeding carriers 1114 in each of the color zone stations 1 are arranged below the multiple loading roller buckets 112 .

[0112] The counter-position distributing device 2 is arra...

Embodiment 2

[0155] Such as Figure 5-Figure 7 As shown, a method for using a combined die opening positioning and distributing system includes the following steps when making ceramic plate products:

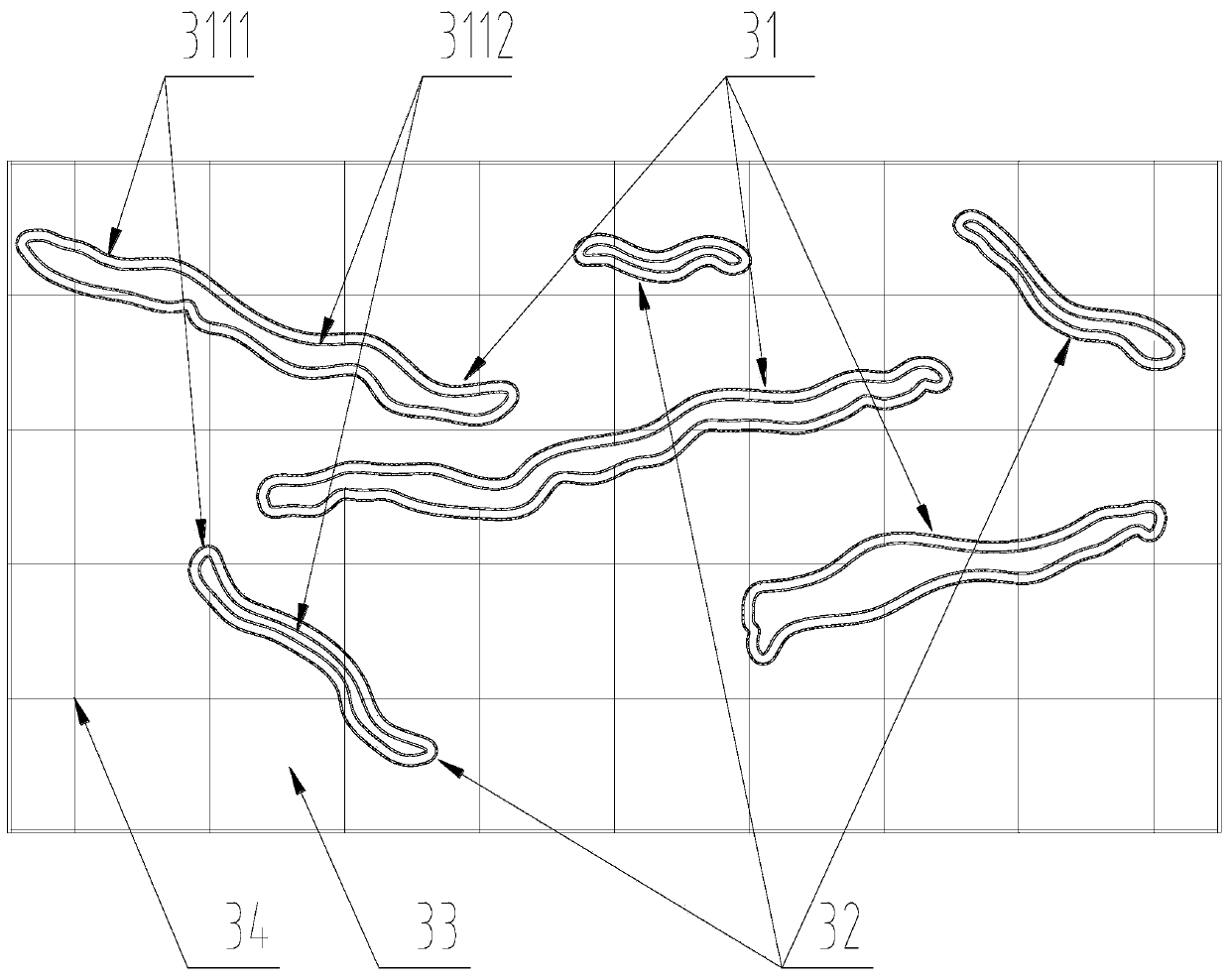

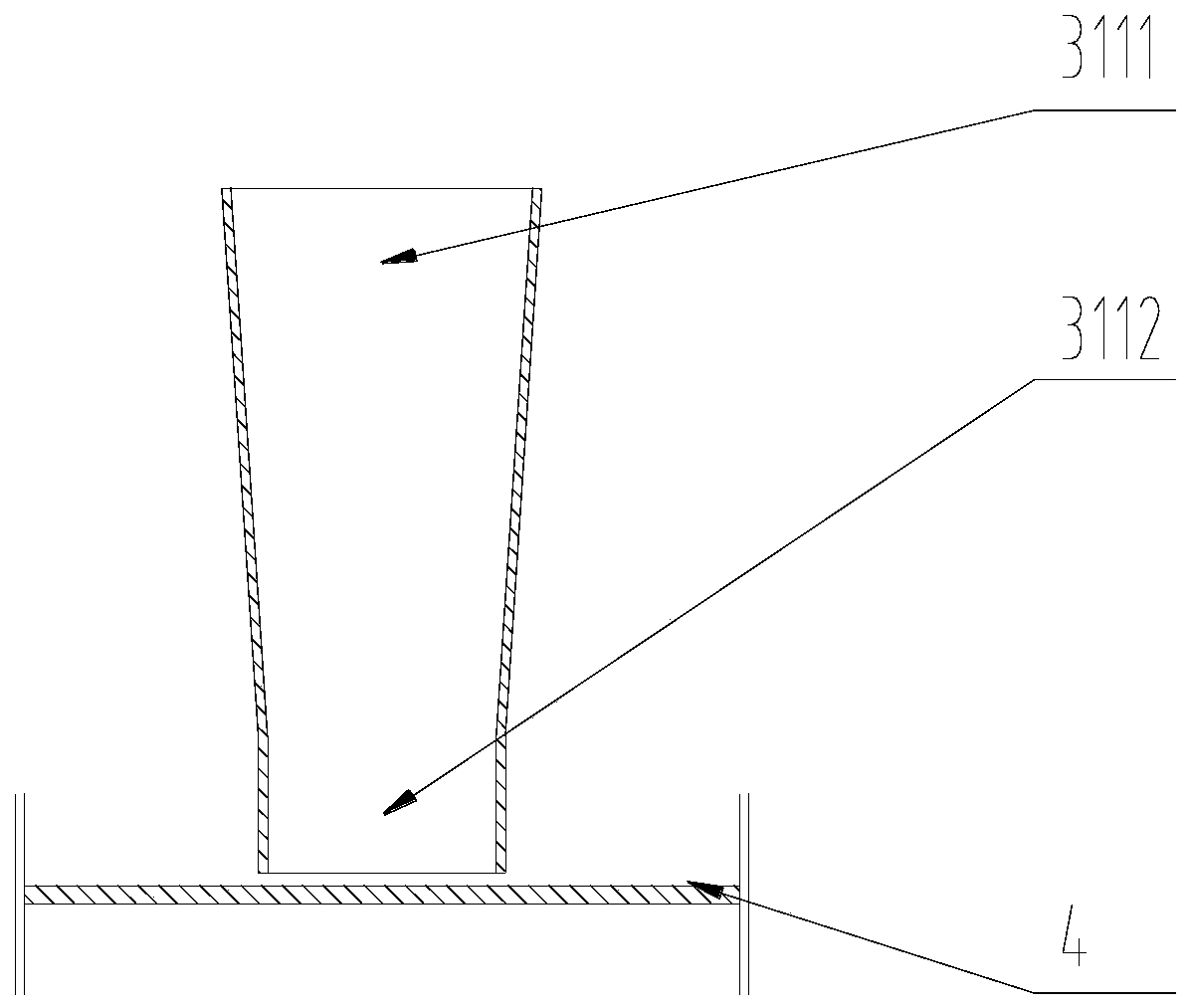

[0156] (1), a, prepare the positioning grid: select the material to be made, set 2-10 settings on the material board, use different single-color raw materials or multi-color mixed materials to form color zone partitions, and reserve according to each color zone Design and manufacture positioning die openings for the designed independent pattern shapes, and form a whole block of positioning grids that carry the overall pattern layout raw materials by combining all color zone and pattern die openings. The height of the die openings is based on the thickness and process conditions of the designed and manufactured products For the predetermined design, the thickness of the grid wall is 0.5mm-3mm; the positioning dies are connected by adjacent grid walls or connected by connecting pieces;

[015...

Embodiment 3

[0190] A method for using a combined die opening alignment and positioning distribution system, wherein a feeding hopper 7 is provided between the scraping device 5 and the alignment distribution device 2, and the lowering hopper 7 is arranged close to the scraping device 5, and finally The pattern raw material of one of the color zone stations 11 is directly placed on the positioning grid 6 through the discharge hopper 7 and the rest of the positioning die after the color zone station 11 raw materials in the previous process have been loaded. 61, thereby completing the layout of the overall color zone station 11 pattern raw materials.

[0191] Based on Embodiment 2, the difference between this embodiment and Embodiment 2 is that after completing the alignment cloth of the second described color area station 11 of step (1)-step (4), the diversion grille 3 Along with the positioning grid 6, the feeding carrier 4 is conveyed to the forming and pressing direction, and when leavin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com