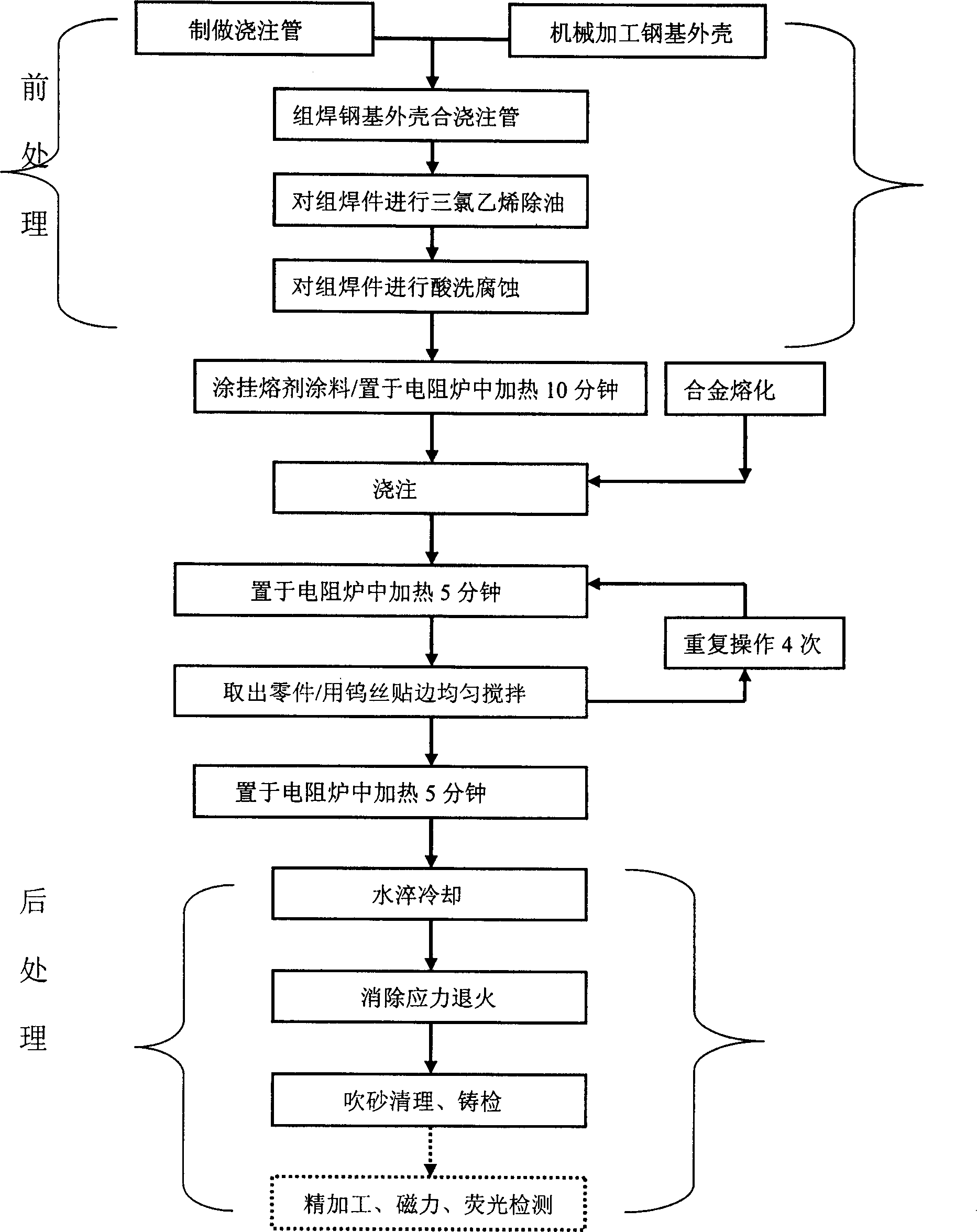

Improvement of working process to bimetal obturge part

A processing technology and bi-metal technology, which is applied in the field of improvement of the processing technology of bi-metal sealing parts, and can solve the problems of repeated entry and exit of parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment technical solution of the present invention will be described in further detail:

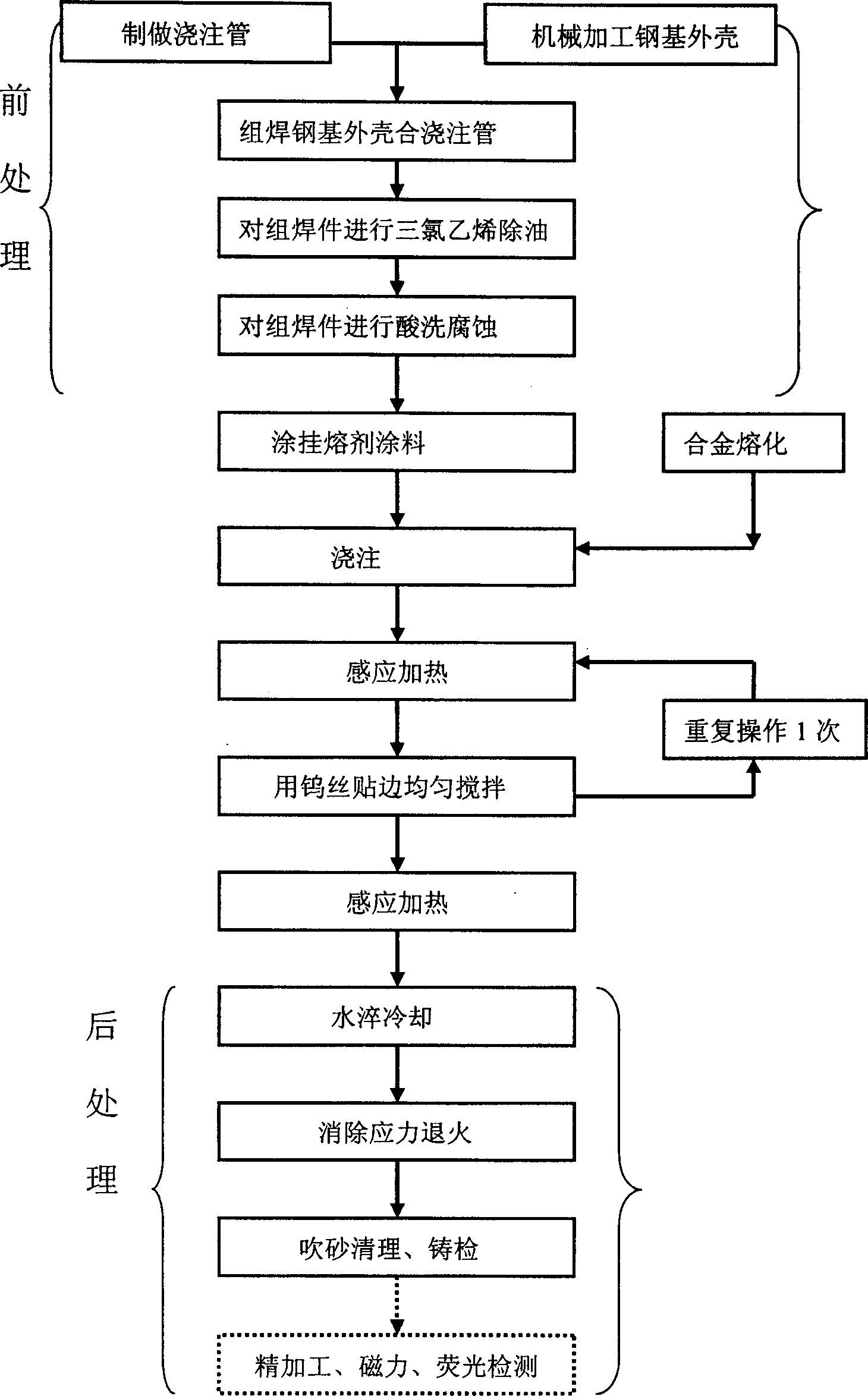

[0017] See attached figure 2 As shown, it expresses the technological process of using electromagnetic induction heating to produce bimetallic sealing parts in this technical scheme.

[0018] In the above process, the pre-treatment, post-treatment and alloy melting procedures are consistent with the existing technical solutions, the technical solution of the present invention only improves the pouring and subsequent related processes, the process steps are:

[0019] (1) Put the parts in the coil of the 7000KHz~9500KHz induction heating furnace, adjust the output voltage to 130~140V, and preheat for 2~3 minutes;

[0020] (2) Adjust the output voltage to 180-230V, preheat it for 3-4 minutes and pour it;

[0021] (3) Adjust the output voltage to 210-330V for heating for 2-3 minutes, and then stir evenly with a tungsten wire;

[0022] (4) Repeat the op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com