Production of copper acetate

A production process, copper acetate technology, applied in carboxylate preparation, organic chemistry, etc., can solve the problems of turbid aqueous solution, high labor cost, cumbersome process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

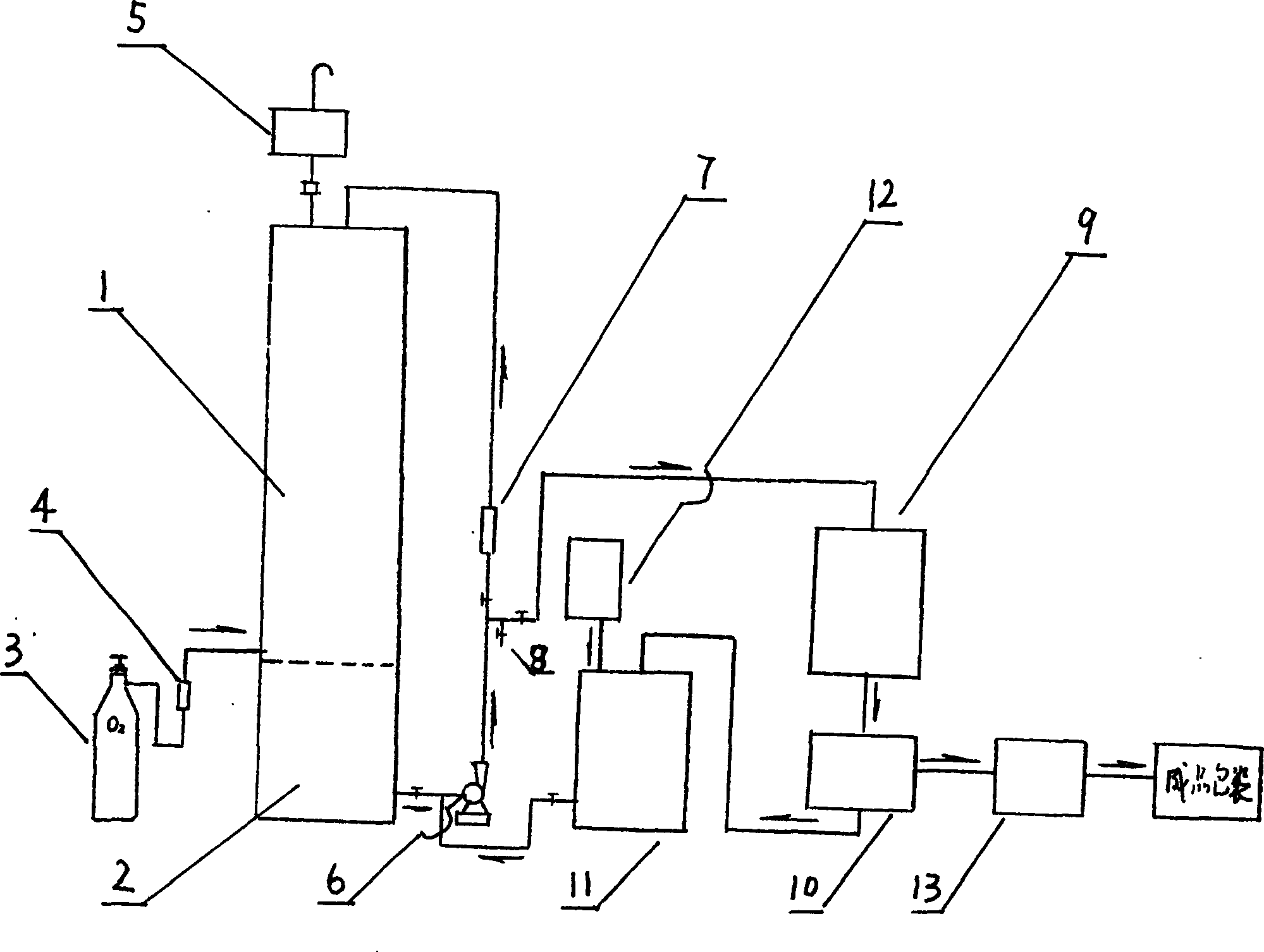

[0014] As can be seen from accompanying drawing, a kind of production technology of copper acetate, its production process is as follows:

[0015] One, glass condenser 5 is installed on the tower of the reaction tower of 2000 kilograms, and 500 kilograms of red copper scraps are packed into the tower body 1 of reaction tower; g / L;

[0016] 3. When the temperature in the tower is gradually raised from normal temperature to 80 degrees, the mother liquor at the bottom of the tower is sprayed in a circular manner through the circulating pump 6, and the oxygen in the oxygen cylinder 3 enters from the junction of the tower body 1 and the tower kettle 2 through the gas rotameter 4 In the tower, the actual reaction requires 8 kg of oxygen. After circulating for two hours, after the mother liquor has crystallization concentration through the sampling port 8, the mother liquor in operation is injected into the crystallizer 9 for crystallization;

[0017] Four, thereafter crystallizatio...

Embodiment 2

[0021] As can be seen from accompanying drawing, a kind of production technology of copper acetate, its production process is as follows:

[0022] One, condenser 5 is installed on the tower of two tons of reaction towers, 500 kilograms of red copper wires are packed into the tower body 1 of reaction towers; / Lift;

[0023] 3. When the temperature in the tower is gradually raised from normal temperature to 80 degrees, the mother liquor at the bottom of the tower is sprayed in a circular manner through the circulating pump 6, and the oxygen in the oxygen cylinder 3 enters from the junction of the tower body 1 and the tower kettle 2 through the gas rotameter 4 In the tower, the actual reaction requires 8 kg of oxygen. After circulating for two hours, after the mother liquor has crystallization concentration through the sampling port 8, the mother liquor in operation is injected into the crystallizer 9 for crystallization;

[0024] Four, thereafter crystallization is sent into cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com