Device for detecting broken yarn through shaft frame and method for locating its address

A technology for yarn breakage detection and setting method, which is applied in the inspection of textile materials, other manufacturing equipment/tools, textiles and papermaking, etc. The effect of setting errors, saving time, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

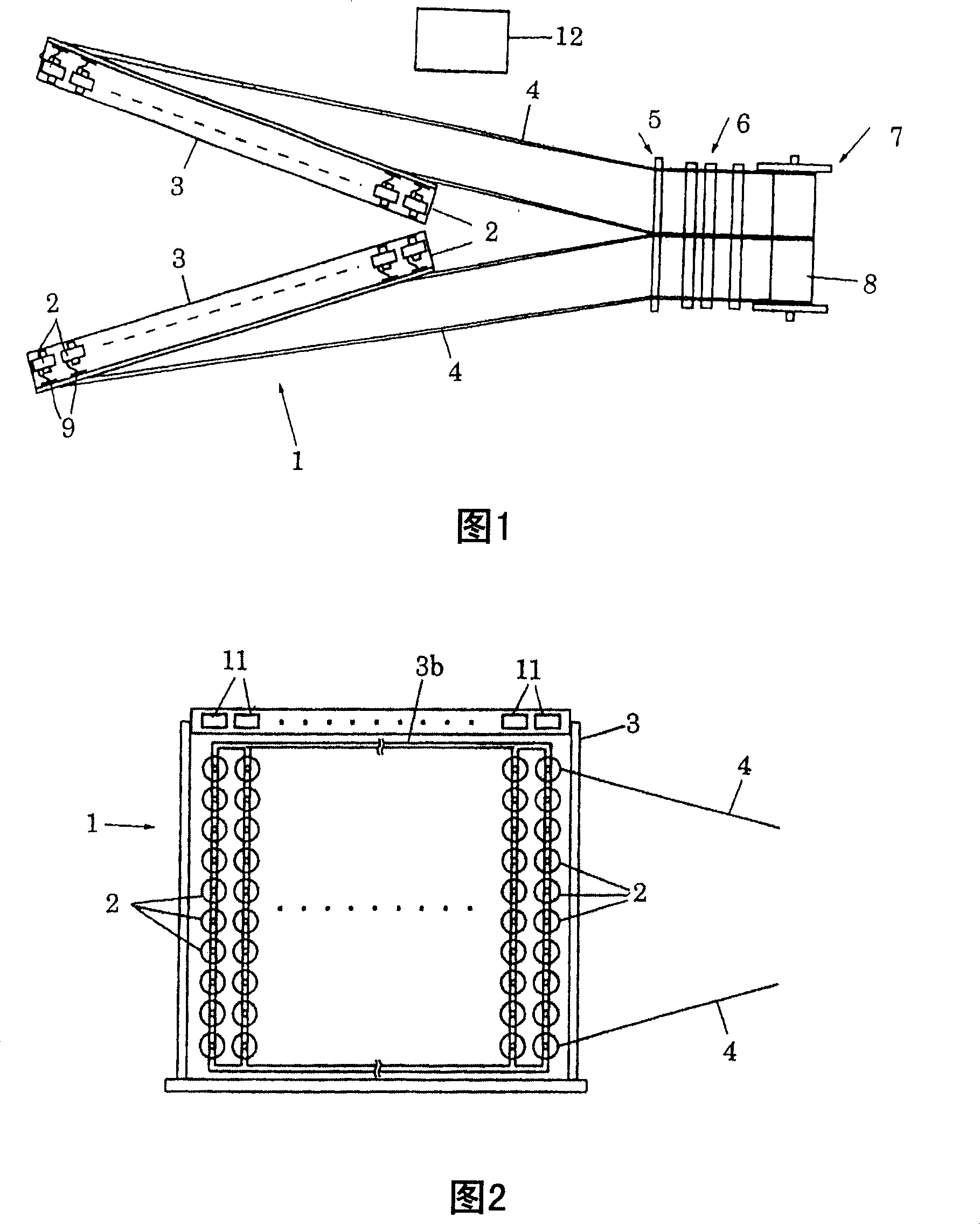

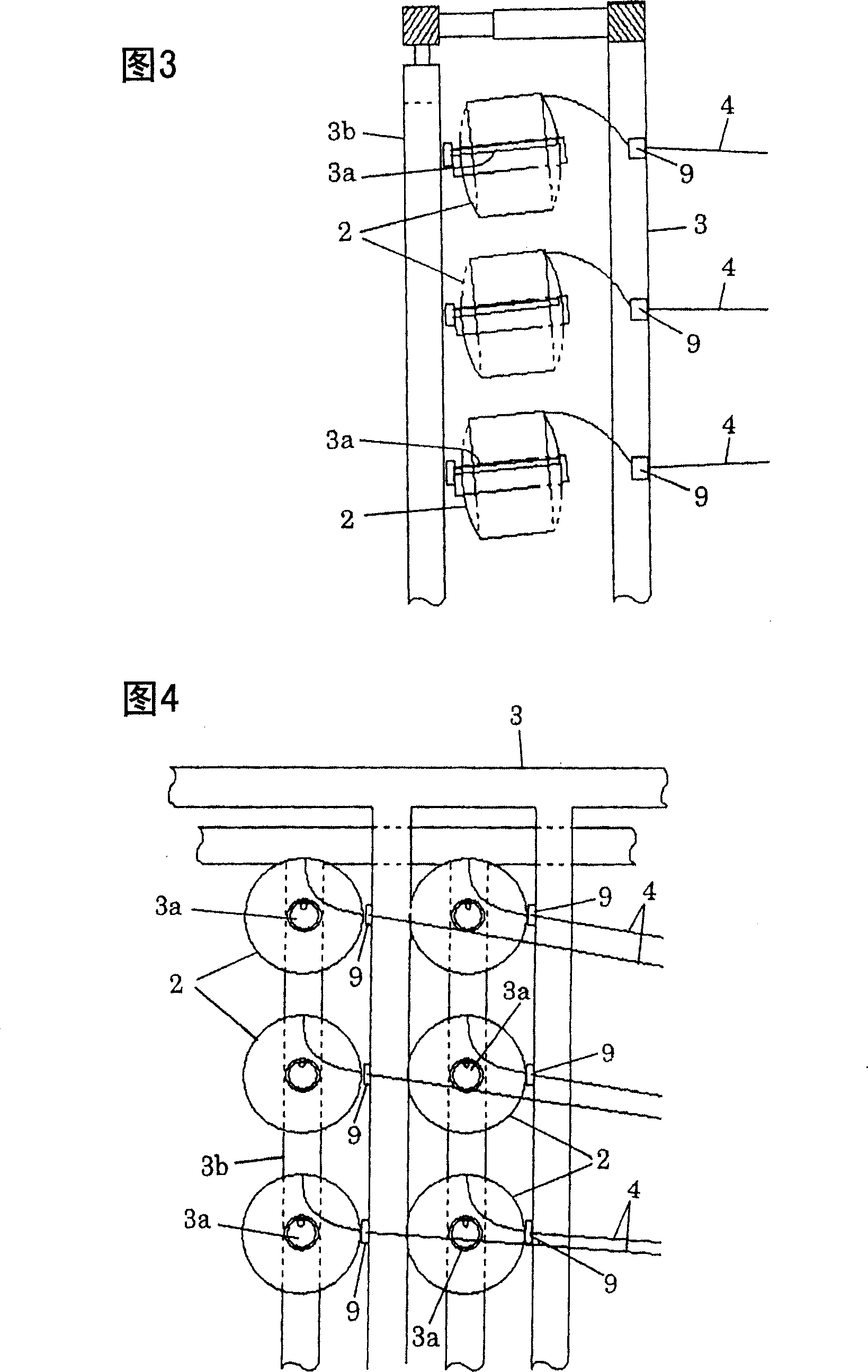

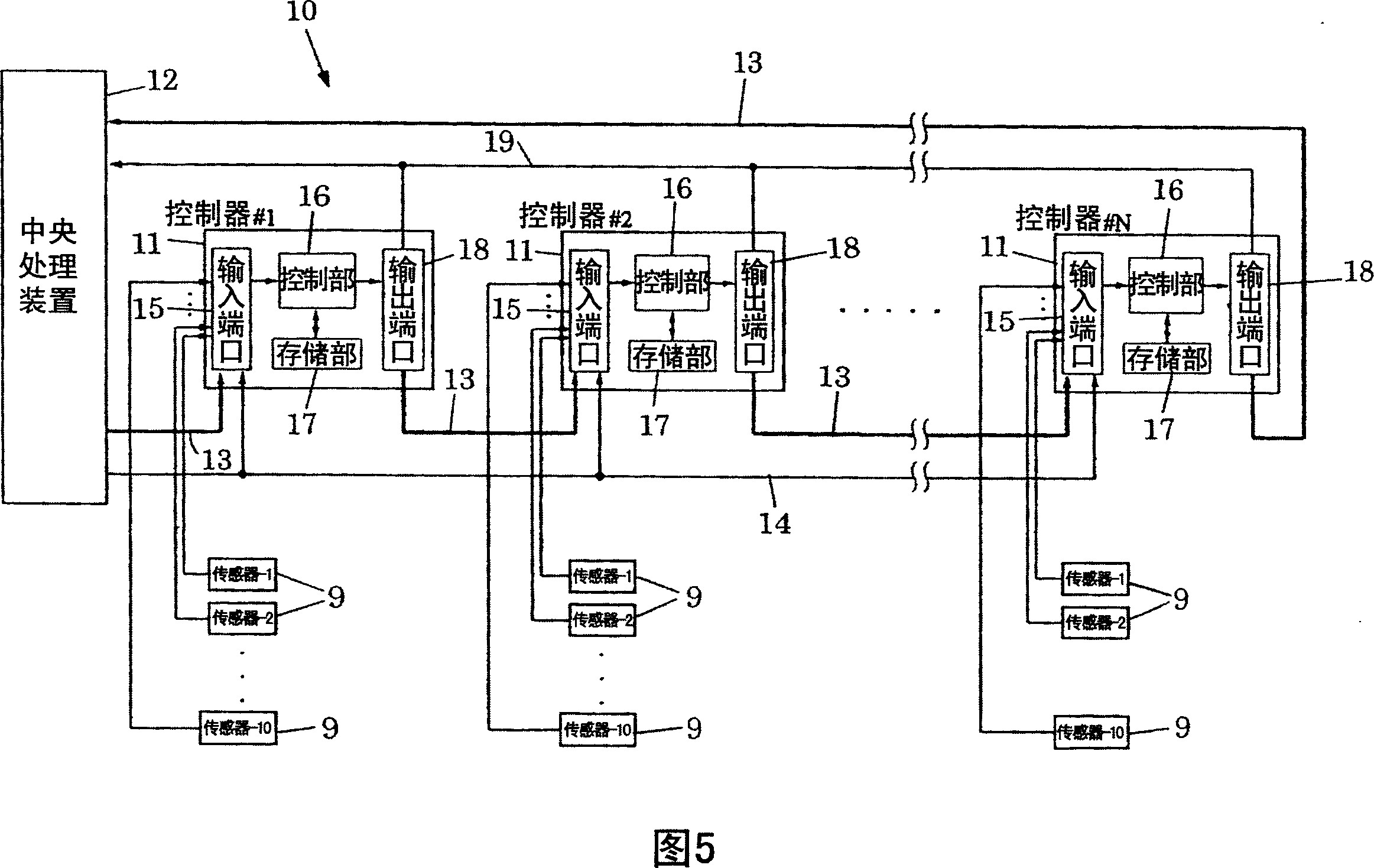

[0022] Figure 1 ~ Figure 4 The mechanical structure of the V-shaped creel device 1 is shown. exist Figure 1 ~ Figure 4 Among them, in order to support a plurality of yarn supply bodies 2, the beam creel device 1 has a V-shaped frame 3 seen in a plan view, and the yarn supply body frame 3b installed on these frames 3 has a plurality of vertical and horizontal parallel lines. Set the support member 3a. According to the illustrated example, the supporting members 3 a are arranged in ten layers in the vertical direction and arranged in N rows in the horizontal direction, and can support 10×N yarn supply bodies 2 in total. The number of yarn suppliers 2 required for warping is arranged at appropriate positions with respect to a total of 10×N supporting members 3 a. At this time, all the 10×N support members 3 a in total support the yarn supply body 2 .

[0023] A plurality of warp yarns 4 drawn from all the yarn supply bodies 2 pass through the yarn breakage sensors 9 provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com