Hollow concrete slab

A technology of concrete hollow slab and cavity, which is applied in the direction of floor slab, formwork/formwork/work frame, structural elements, etc., can solve the problems of high rigidity and inability to form the equivalent two-way slab with well-shaped rib.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

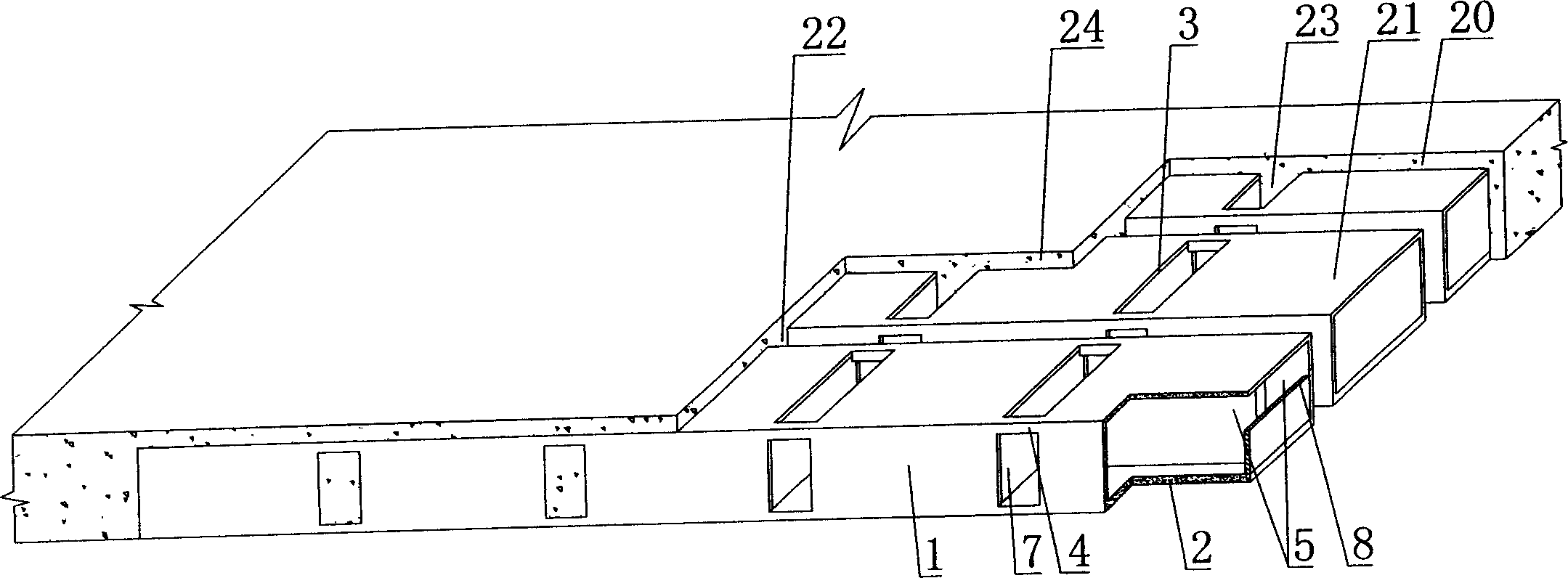

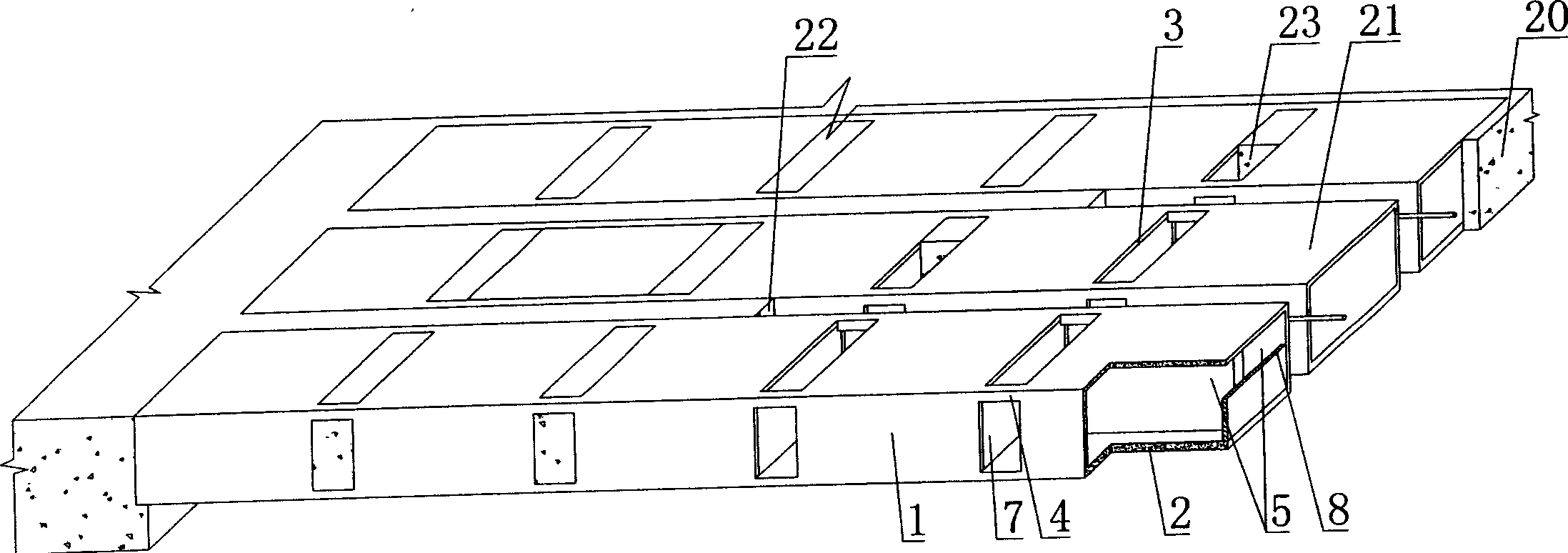

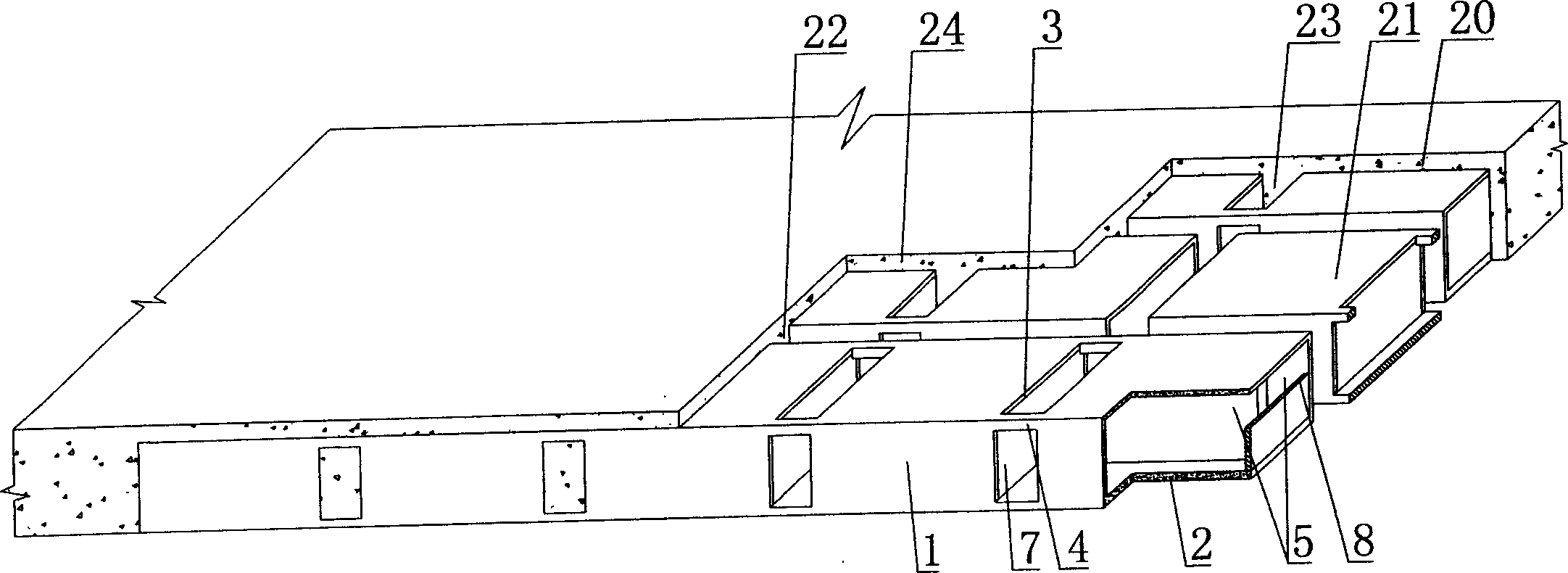

[0049] As shown in the accompanying drawings, the present invention includes cast-in-place reinforced concrete 20, cavity members 21 for filling, the cavity members 21 for filling are arranged alternately and wrapped in the cast-in-place reinforced concrete 20, and the cavity members 21 for filling are mutually arranged. There are cast-in-place concrete ribs 22 between them, and the cavity member 21 for filling includes a long tube body 1 with at least one longitudinal long hole. The lower tube wall 2 is a whole-length integral flat plate, and the other tube walls of the long tube body 1 have at least one transverse rib groove 3 perpendicular to or oblique to the tube axis, and at least one tube wall between the transverse rib grooves 3 There are connected connectors 4, and there are more than two long tube holes 5 in the long tube body 1, and there are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com