Modular rear projection display and combined device used thereof

A technology for display devices and combined devices, which is applied in the direction of using projection device image reproducers, projectors with built-in screens/external screens, and projection devices, which can solve the problem of costly mold opening and development costs, and rear projection display Problems such as increased device cost and difficulty in product assembly have achieved the effects of saving development costs, reducing inventory opportunities, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

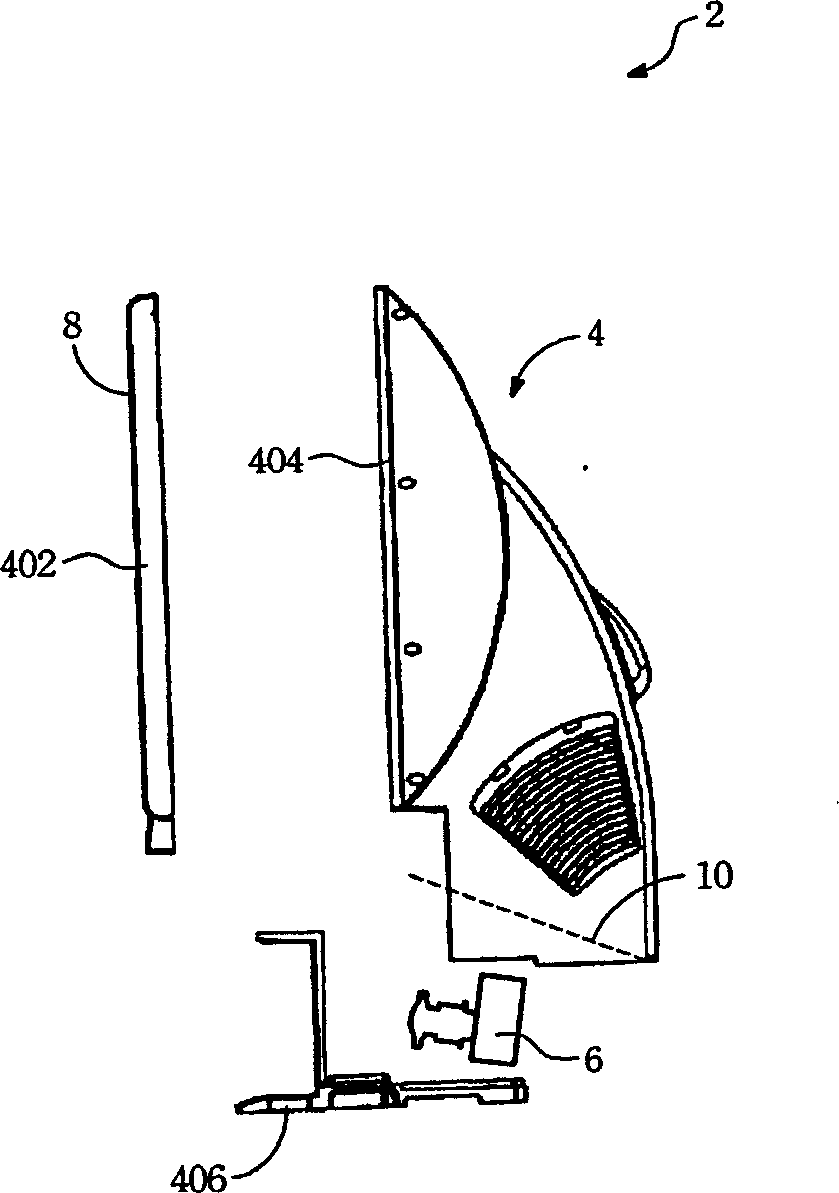

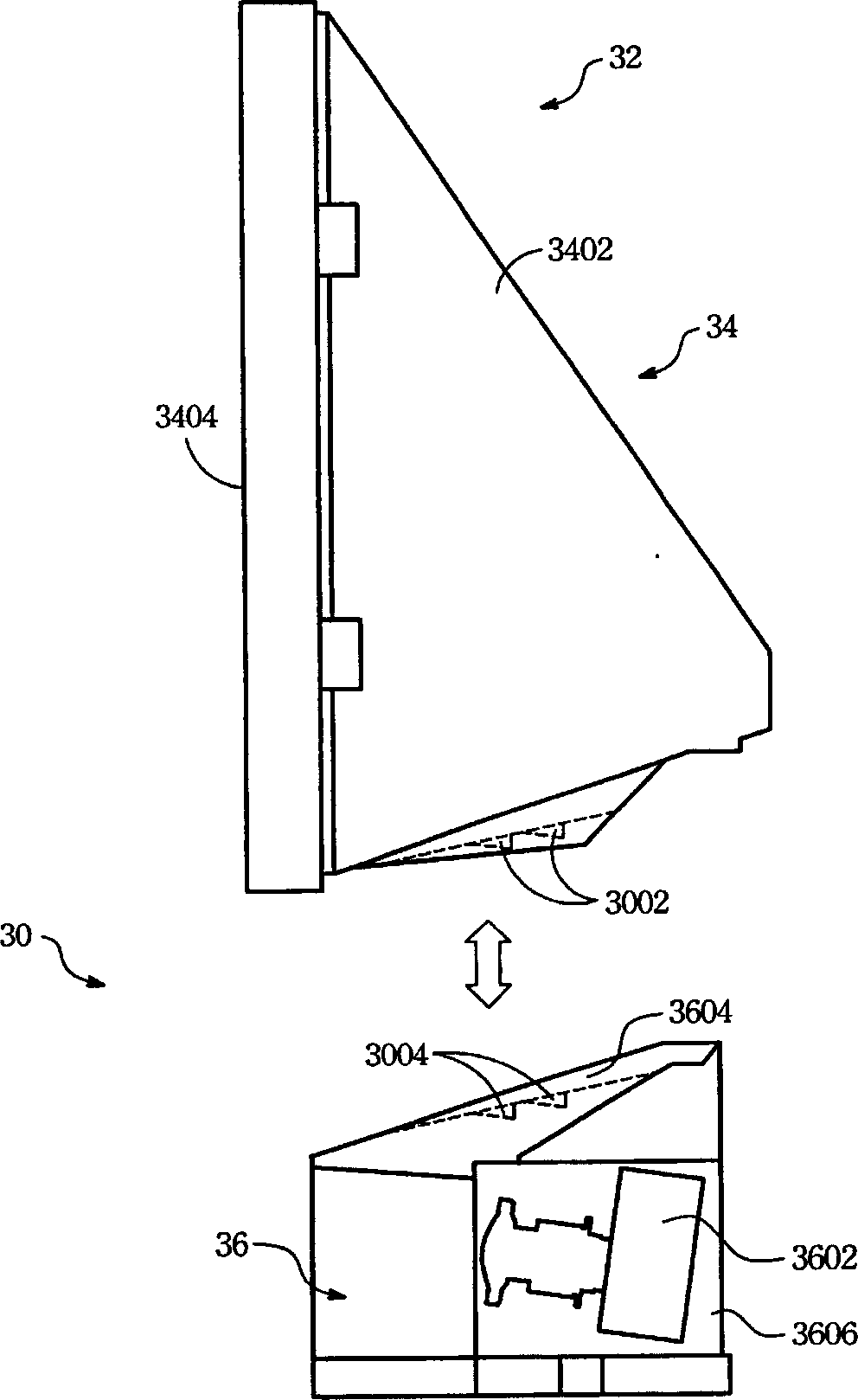

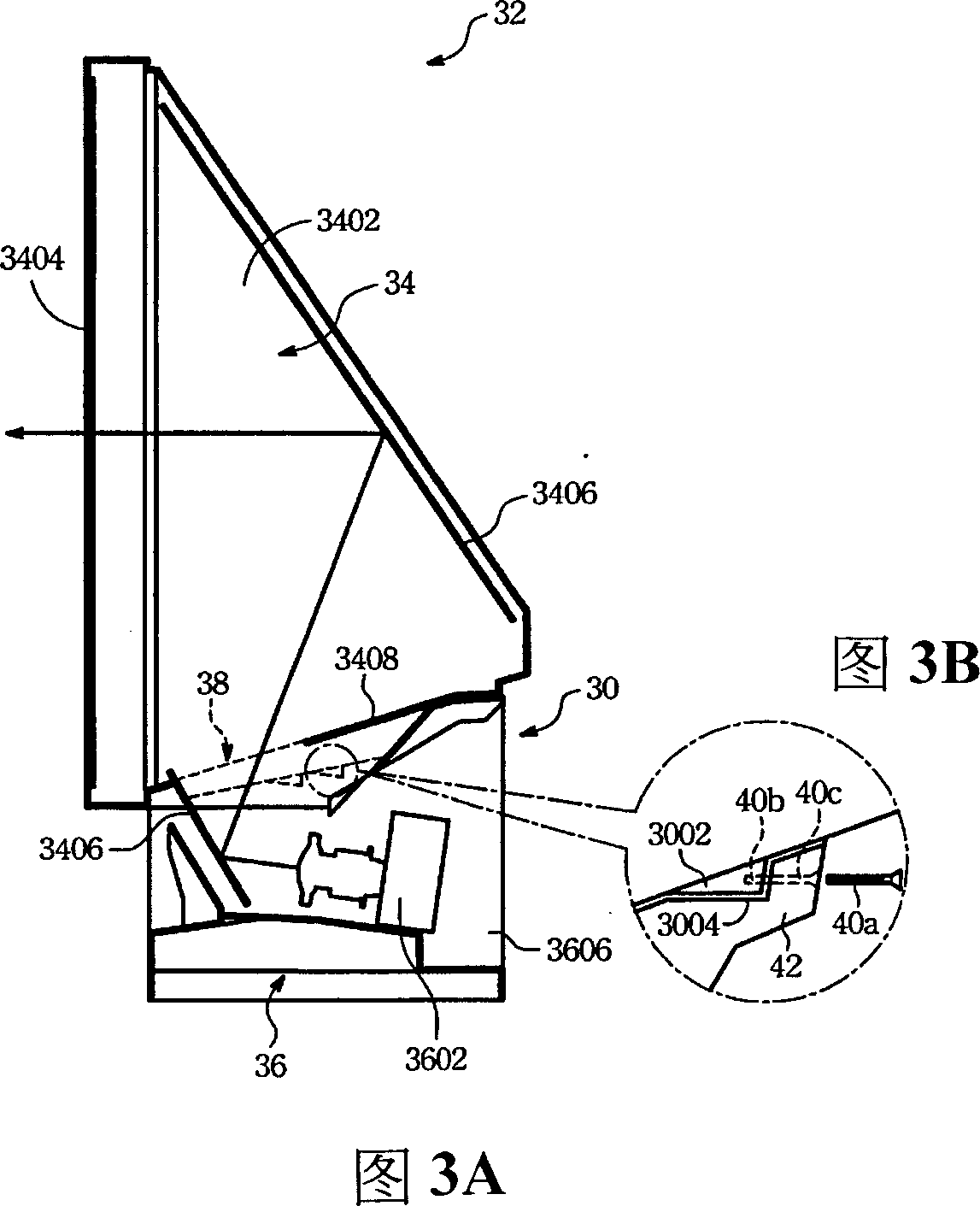

[0048] see figure 2 and Figures 3A, 3B, figure 2It is an exploded schematic view of the combination device 30 of the present invention. FIG. 3A is a combined schematic view of the combination device 30 of the present invention. The present invention relates to a modularized rear projection display device 32 and a combination device 30 for the rear projection display device 32, using the combination device 30 to combine the modularized screen module 34 in the rear projection display device 32 And the optomechanical module 36. The optical engine module 36 includes an optical engine housing 3606 and an optical engine 3602 disposed in the optical engine housing, and the screen module 34 includes a screen housing 3402 , a screen 3404 , and a reflector 3406 .

[0049] The screen 3404 is arranged on the front of the screen housing 3402 . The reflector 3406 is arranged inside the screen housing 3402, and is used to reflect the image light from the bottom light engine 3602 and pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap