Assembly aid and method for positioning a hinge in a reproducible manner

A technology for installation aids and hinges, which is applied in the direction of hinges with pins, wing leaf parts, door/window accessories, etc., which can solve problems such as inclination, and achieve the effect of saving materials and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

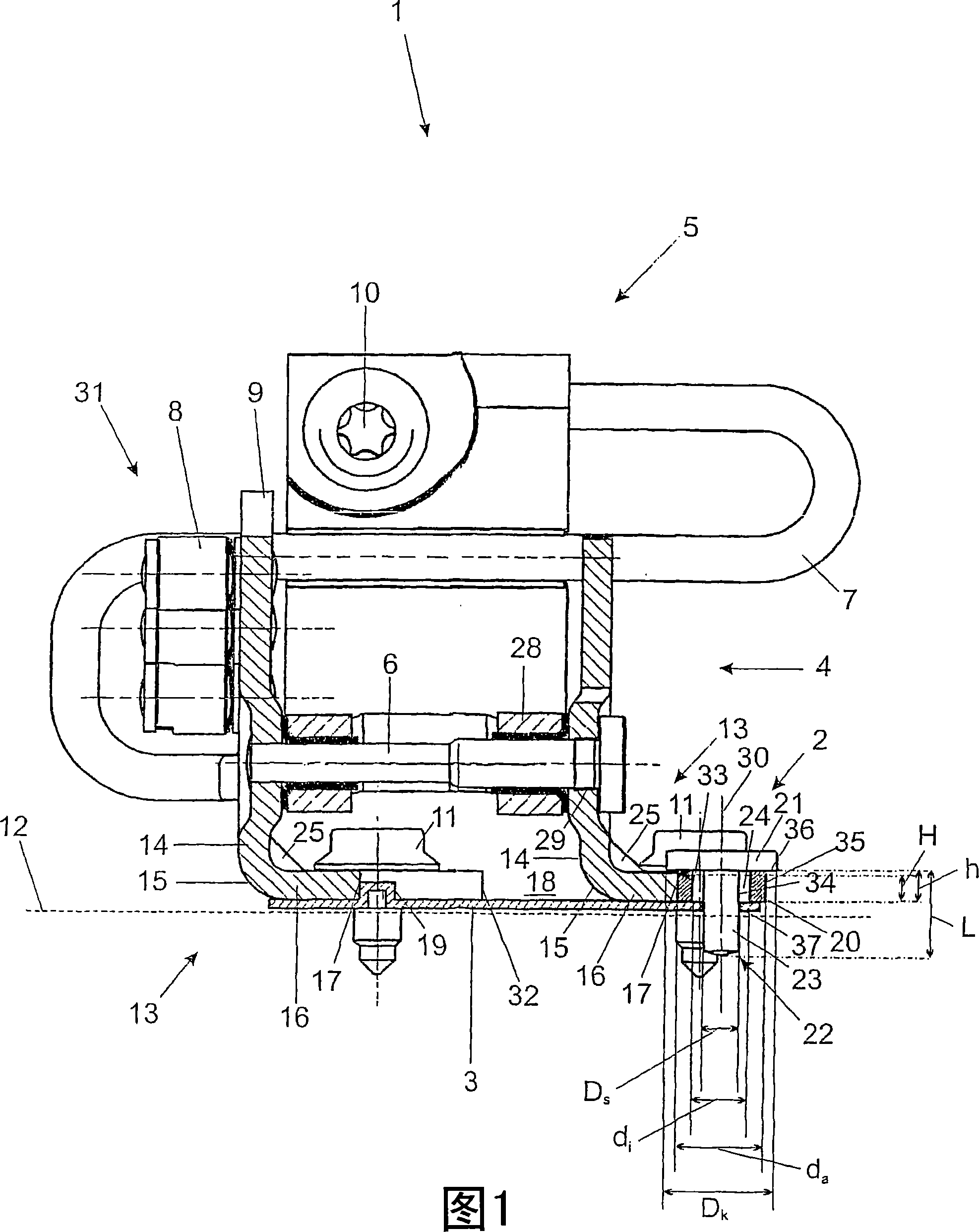

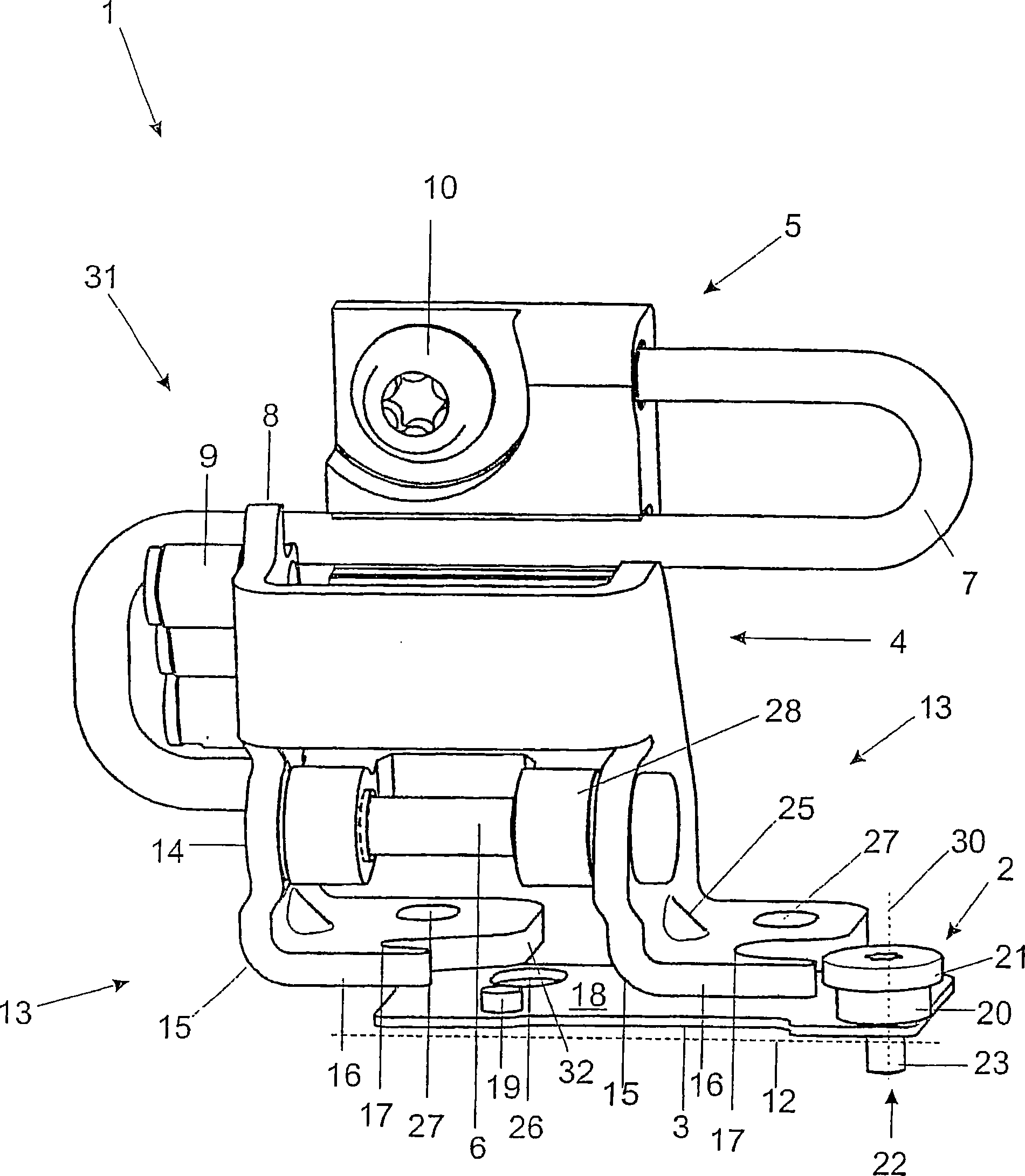

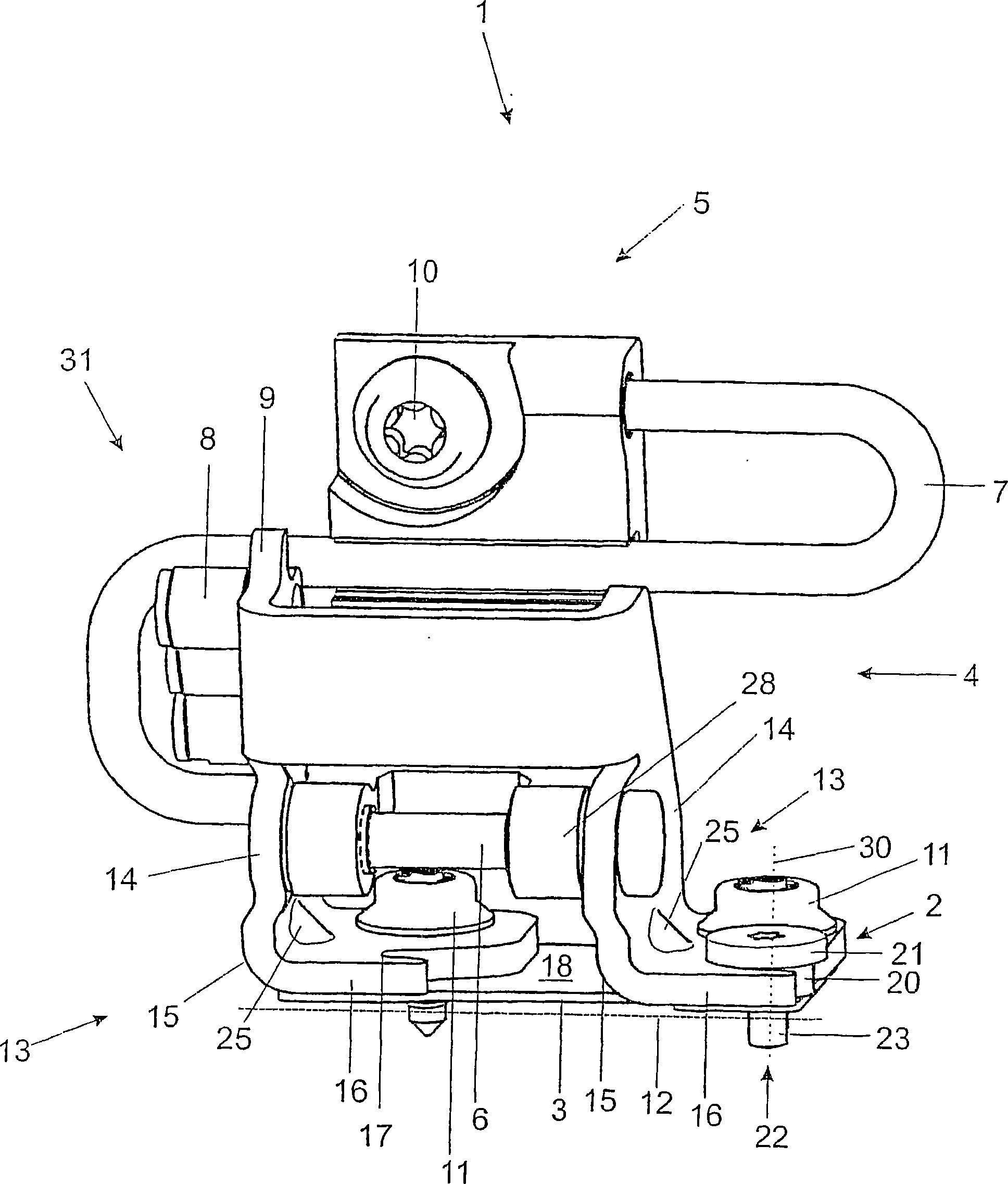

[0034] figure 1 A hinge 1 is shown connected to the body (not shown) of a motor vehicle. A door indicated by a dashed line 12 is fastened to the hinge 1 in the adjusted position by using the mounting aid 2 .

[0035] The hinge 1 with an integrated door stop 31 comprises a first hinge part 4 (in figure 1 shown in a partially cutaway manner), the second hinge part 5 and the hinge pin 6. The integrated door brake 31 has a torsion bar 7 bent in an S-shape and a part against an abutment element 8 on an abutment plate 9 designed as one piece with the first hinge part 4 .

[0036] The second hinge part 5 is connected to the vehicle body (not shown) by fastening screws 10 , while the first hinge part 4 is fixed to the door 12 by fastening screws 11 . The first hinge part 4 has two fastening parts 13 each comprising a leg 14 accommodating the hinge pin 6 , an angled portion (or bent portion) 15 and a fastening region 16 bent almost at a right angle. The fastening area 16 has a thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com