The wiring harness structure of electric motorcycle

A technology for electric motorcycles and wiring harnesses, applied in the field of wiring harness structures, can solve problems such as coiled arrangement of difficult low-voltage wiring harnesses, control signal line length, etc., and achieve the effects of space utilization efficiency, impact reduction, and effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

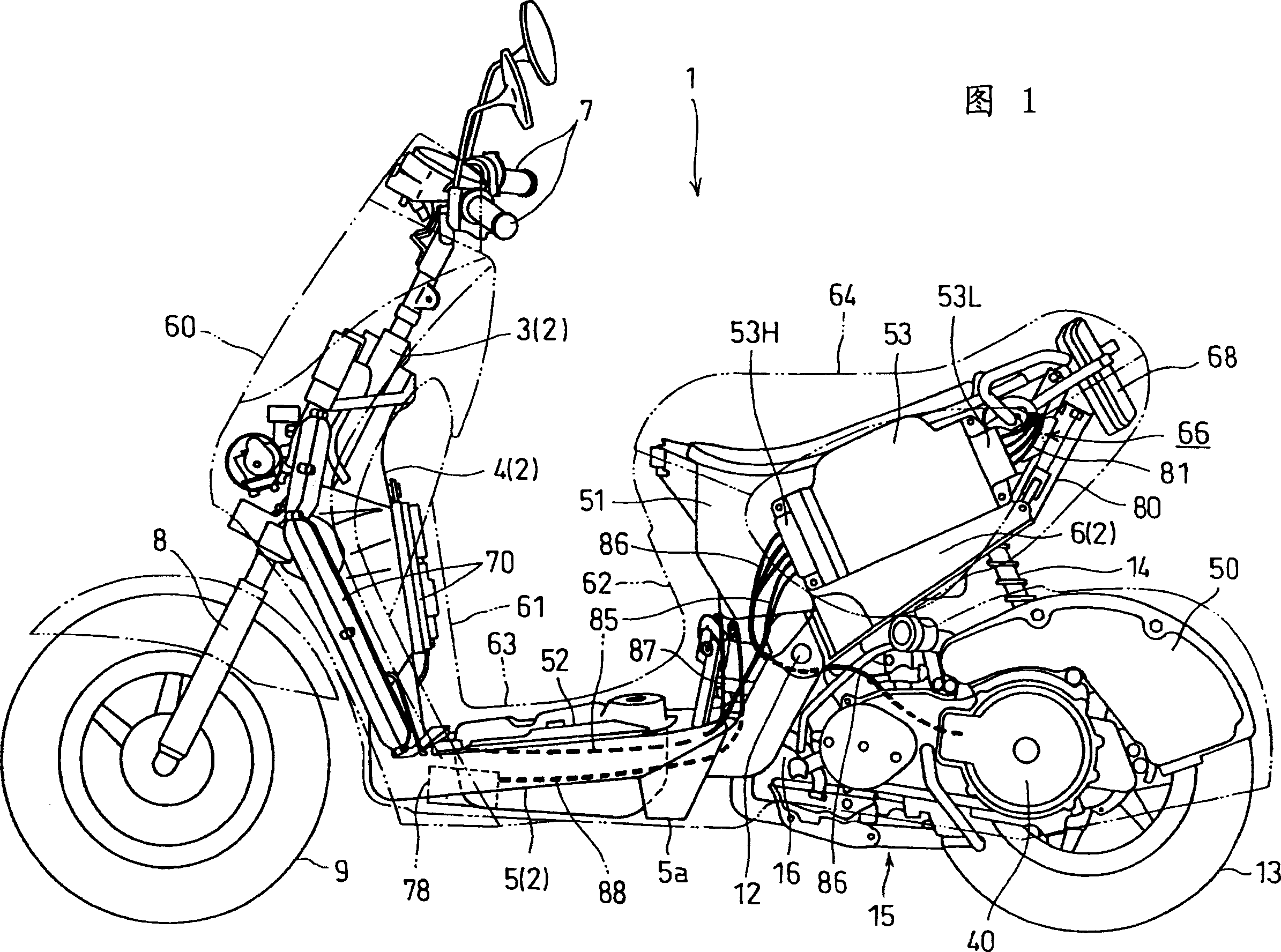

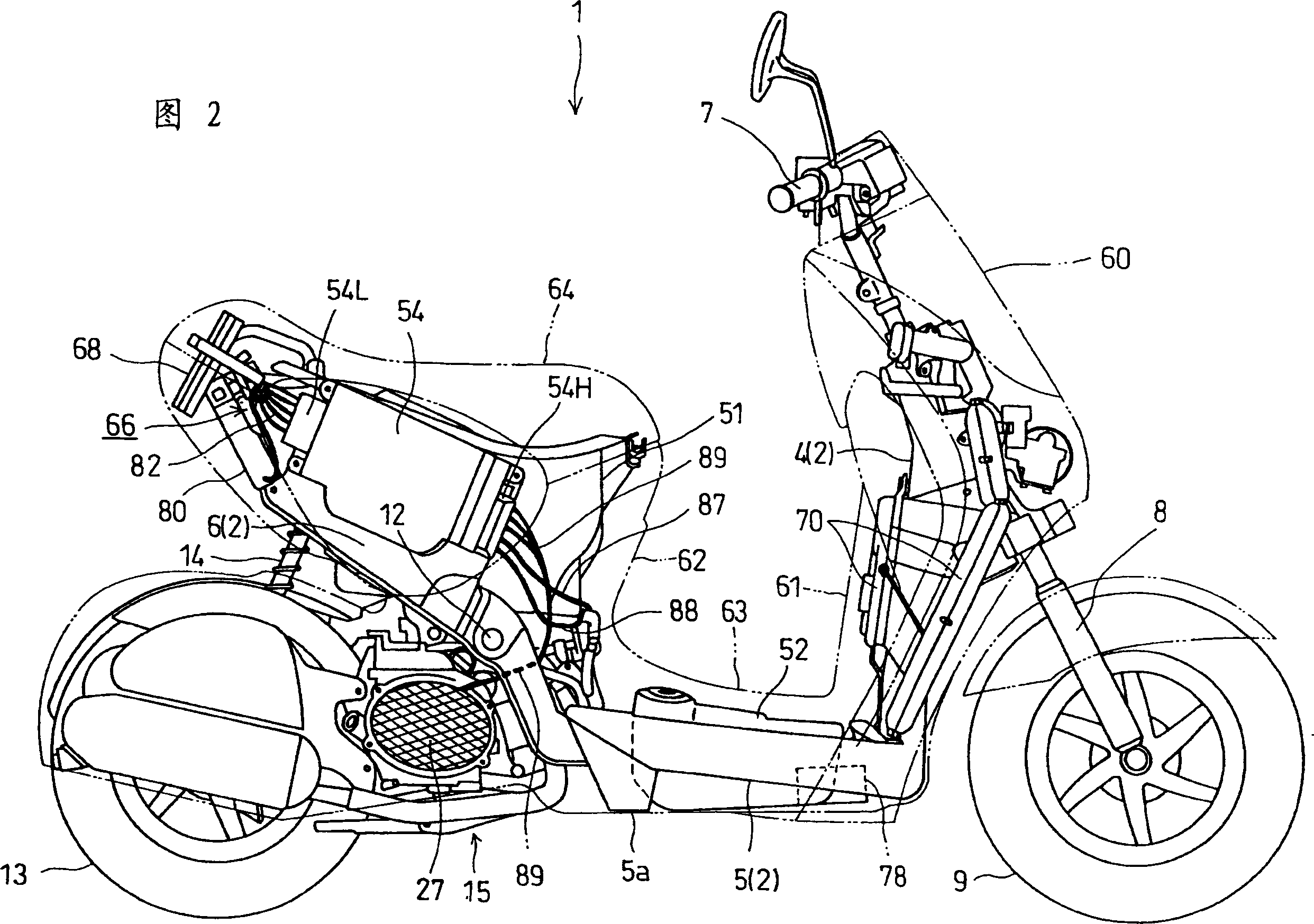

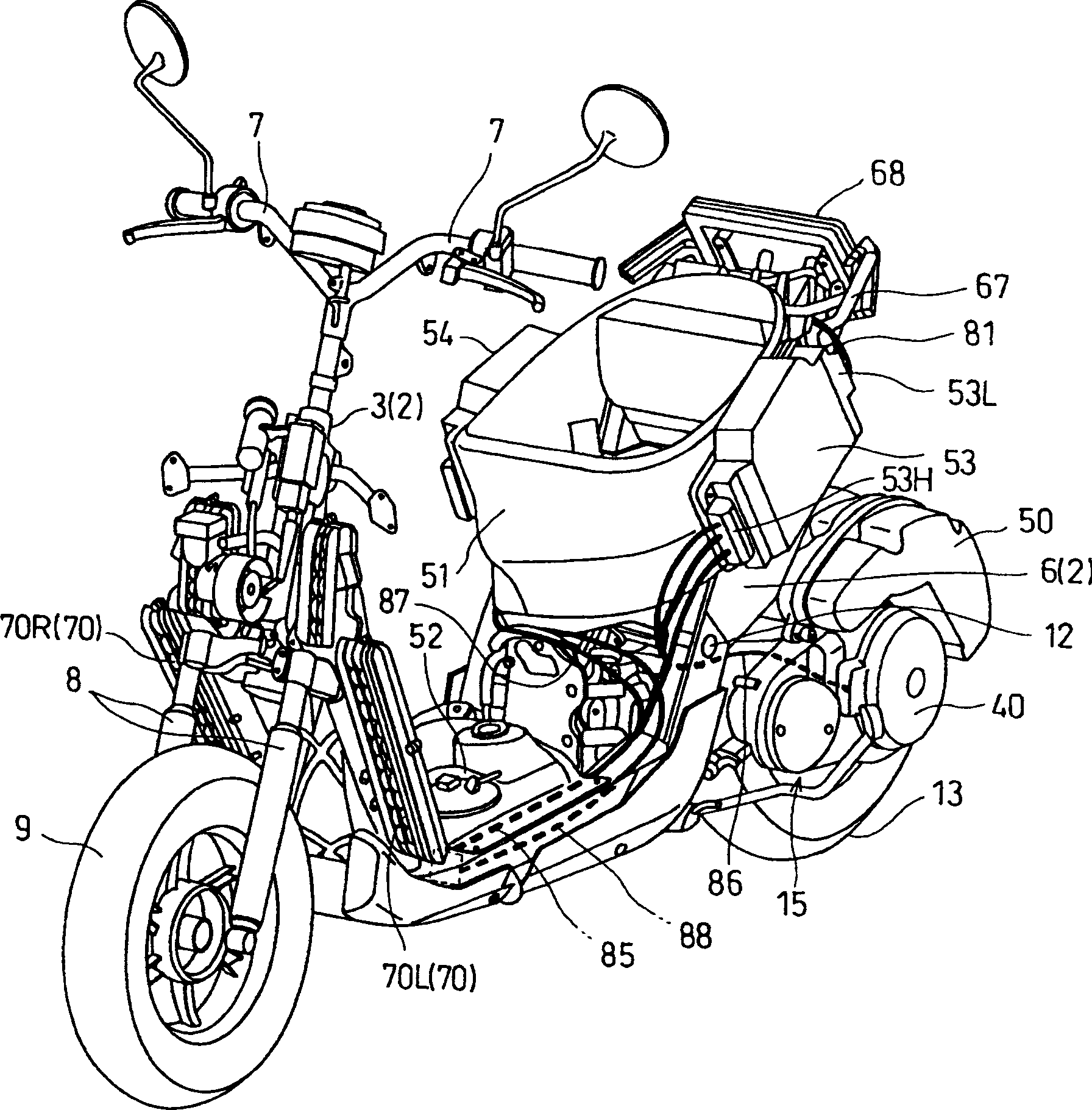

[0060] Below, refer to Figure 1- Figure 7 An example of the present invention will be described.

[0061]The electric vehicle of the present embodiment is a composite small-wheeled electric motorcycle 1 equipped with an internal combustion engine. Fig. 1 is a left side view of the above-mentioned small-wheeled electric motorcycle 1 represented by a virtual box (dash-dotted line), Fig. 2 It is the right side view of the above electric scooter, image 3 It is a perspective view with the cover removed.

[0062] The vehicle frame 2 of this small-wheeled electric motorcycle 1 has: a front frame part 4, which extends obliquely downward from the head pipe 3 to the rear of the vehicle body; It is bent and extended approximately horizontally; the same pair of left and right die-cast aluminum rear frame parts 6, the front end of which is connected to the rear end of the above-mentioned intermediate frame part 5 connected by the cross beam 5a, and extends obliquely upward backward.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com