Large span suspended cable structure and its construction method

A large-span, cable-suspension technology, applied to building components, building structures, roofs, etc., to achieve reliable construction, flexible interior layout, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

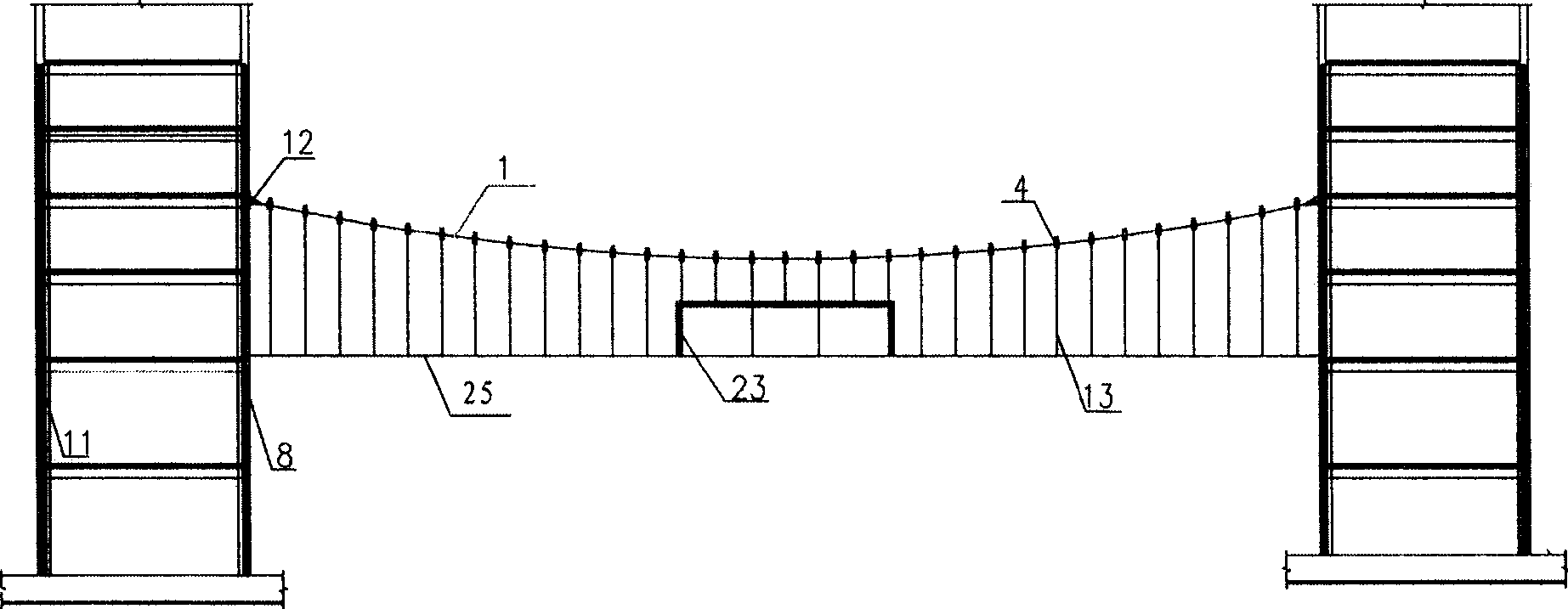

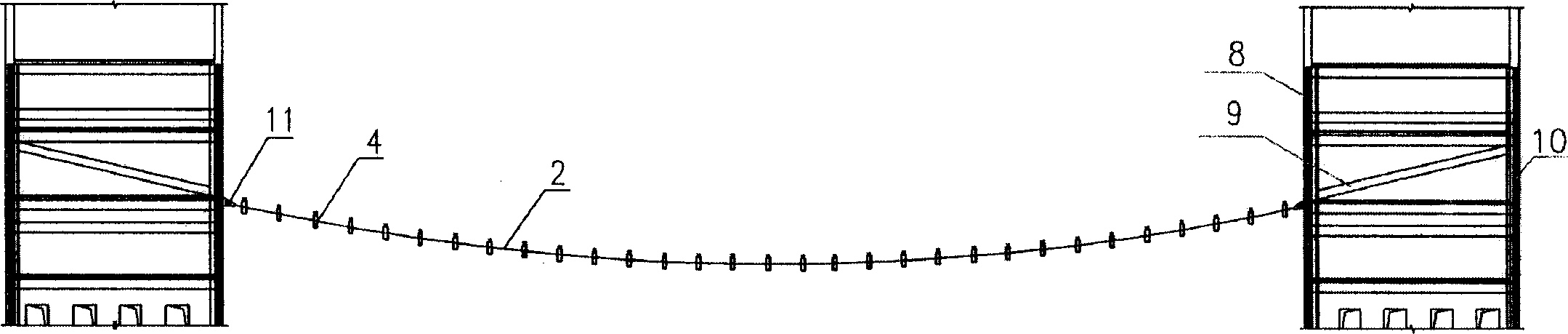

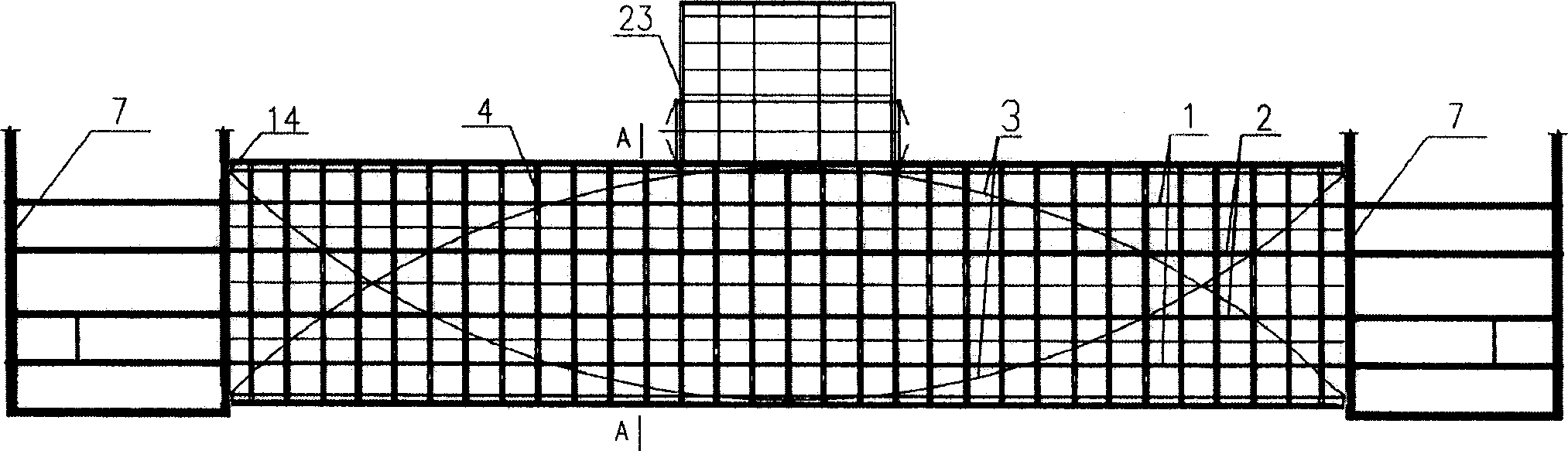

[0043] Examples see Picture 1-1 0, this is a long-span suspension cable structure and its construction method. The two underground floors of the building are connected as a whole. There are two towers on the ground, and a suspension cable structure with a span of 63m is designed between the two towers. The suspension cable structure is mainly It is supported by four suspension cables and two wind cables. The four main suspension cables include two sideline suspension cables 1 and two centerline suspension cables 2. Steel beams 4 are arranged on the suspension cables with a spacing of 2.0m. Glass roof panels 17 are installed on the steel beams. Stay cables 13 are hung at both ends of the steel beam, and glass curtain wall vertical plates 22 are installed on the stay cables. The specific structure is as follows:

[0044] Steel frame 7: set in the main structure of the buildings at both ends respectively, the lower end of the steel frame is fixedly connected with the foundatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com