Hinge

A hinge and hinge shaft technology, applied in the field of hinges, can solve the problems of low precision, appearance pollution, and shorten the life of the hinge, and achieve the effects of high hinge precision, flexible operation and low noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

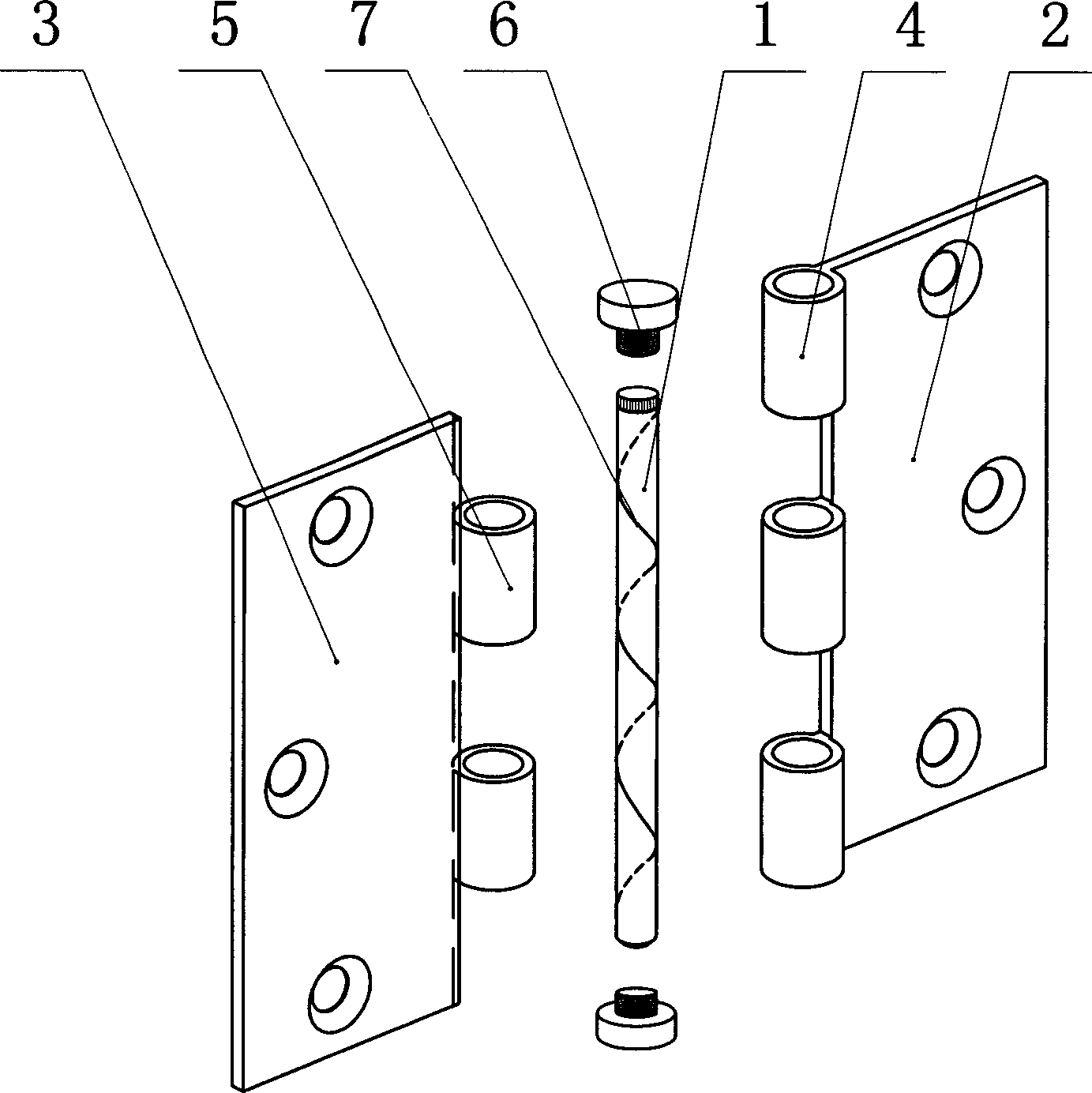

Embodiment 1

[0016] Such as figure 1 As shown, the present invention includes a hinge shaft core 1, a fixed leaf 2, a movable leaf 3, and a plug 6. The fixed leaf 2 is provided with a three-tooth fixed shaft sleeve 4, and the movable leaf 3 is provided with The two-toothed moving shaft sleeve 5, the lower end of the hinge shaft core 1 passes through the fixed shaft sleeve 4 and the moving shaft sleeve 5 at intervals, and the upper and lower ends are blocked by the said plug 6 which also serves as a dustproof and decorative function, The outer periphery of the hinge shaft core 1 is provided with a lubricating oil groove, and the lubricating oil groove is a helical groove 7 surrounding the outer periphery of the hinge shaft core 1 .

[0017] Before the hinge shaft core 1 penetrates the fixed shaft sleeve 4 and the moving shaft sleeve 5, apply lubricating oil to the helical groove 7 on the outer periphery of the hinge shaft core 1, and the lubricating oil will be stored in the helical groove ...

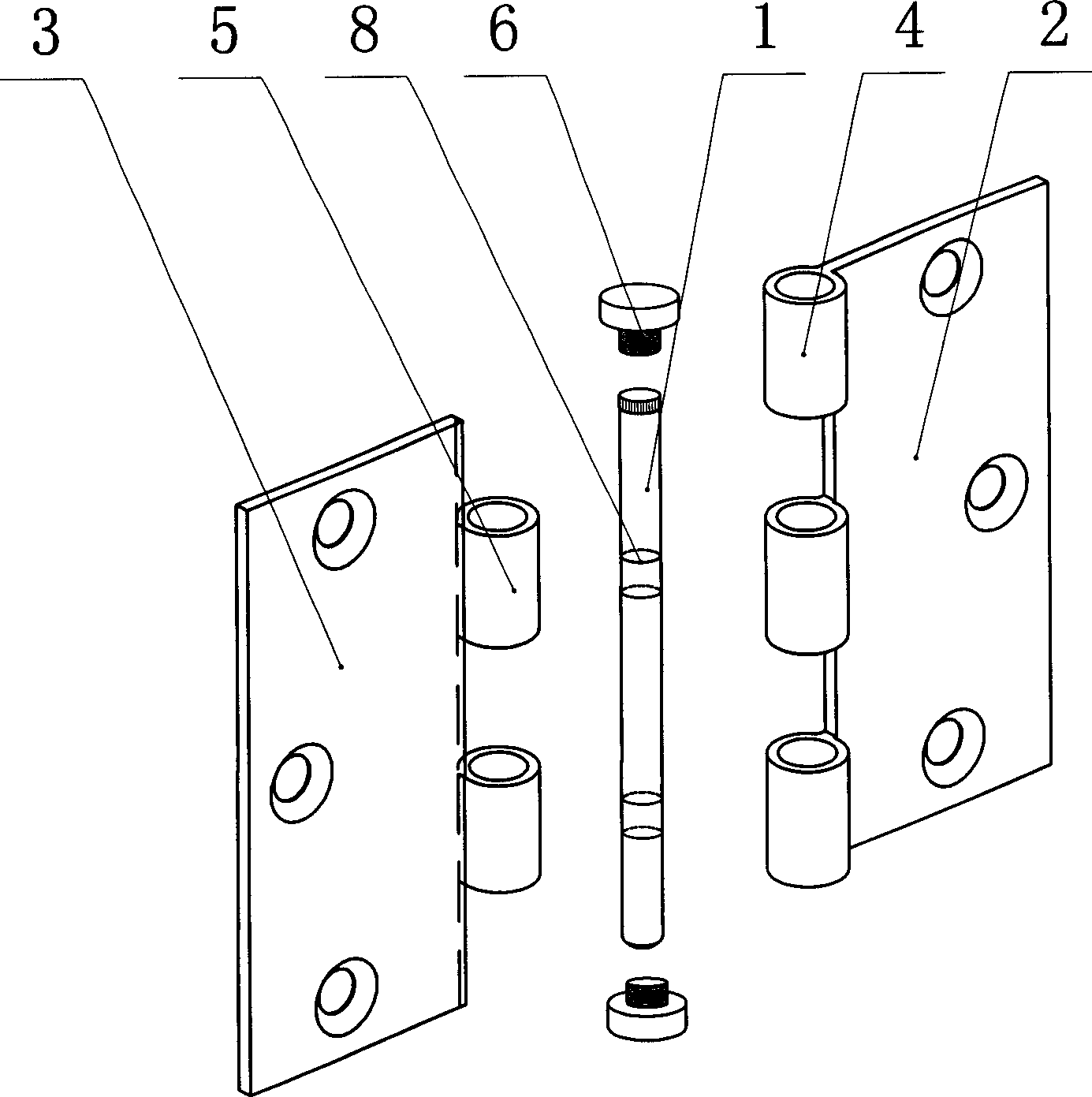

Embodiment 2

[0019] Such as figure 2 As shown, the lubricating oil groove in this embodiment is an annular groove 8 perpendicular to the central axis of the hinge shaft core 1, and the annular groove 8 is arranged on the joint where the hinge shaft core 1 and the moving sleeve 5 cooperate. on the periphery.

[0020] All the other features are the same as in Embodiment 1.

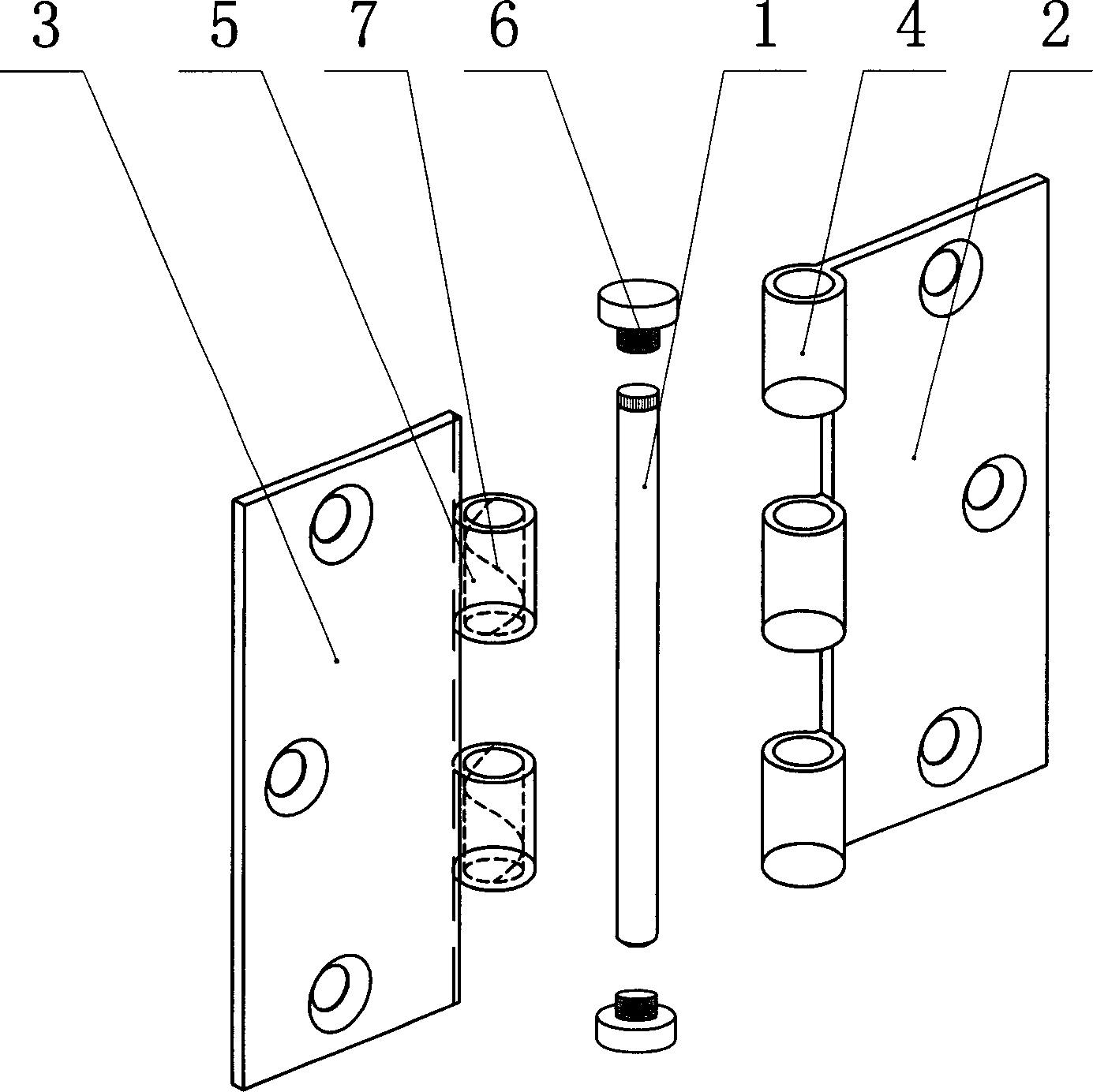

Embodiment 3

[0022] Such as image 3 As shown, the present invention includes a hinge shaft core 1, a fixed leaf 2, a movable leaf 3, and a plug 6. The fixed leaf 2 is provided with a three-tooth fixed shaft sleeve 4, and the movable leaf 3 is provided with The two-toothed moving shaft sleeve 5, the lower end of the hinge shaft core 1 passes through the fixed shaft sleeve 4 and the moving shaft sleeve 5 at intervals, and the upper and lower ends are blocked by the said plug 6 which also serves as a dustproof and decorative function, A lubricating oil groove is provided on the inner hole wall of the moving shaft sleeve 5 , and the lubricating oil groove is a helical groove 7 surrounding the inner hole wall of the moving shaft sleeve 5 .

[0023] All the other features are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com