Thermistor

一种热敏电阻、热敏电阻元件的技术,应用在电阻器、不可调金属电阻器、电路等方向,能够解决室温电阻值低、室温电阻值升高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065]

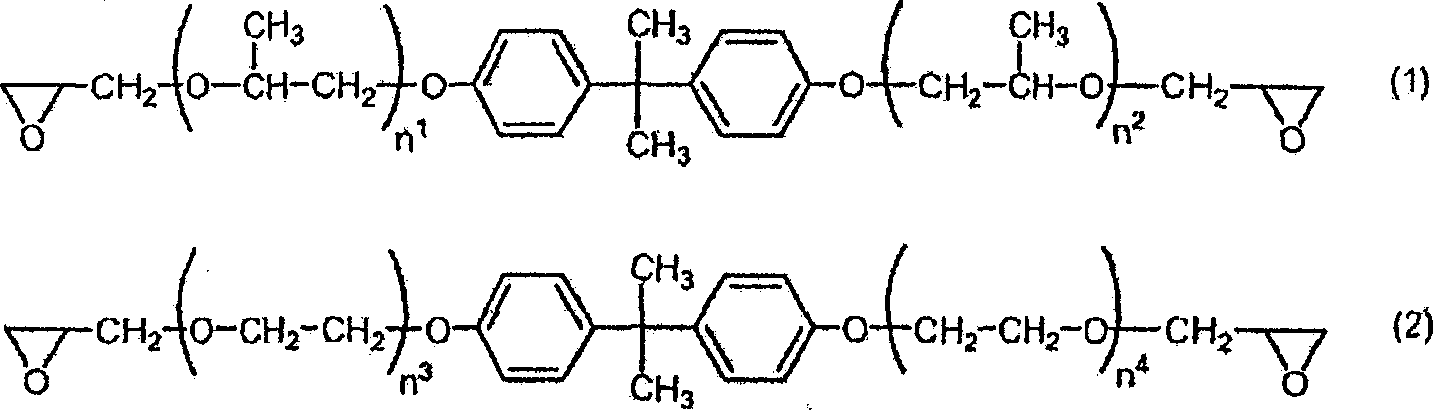

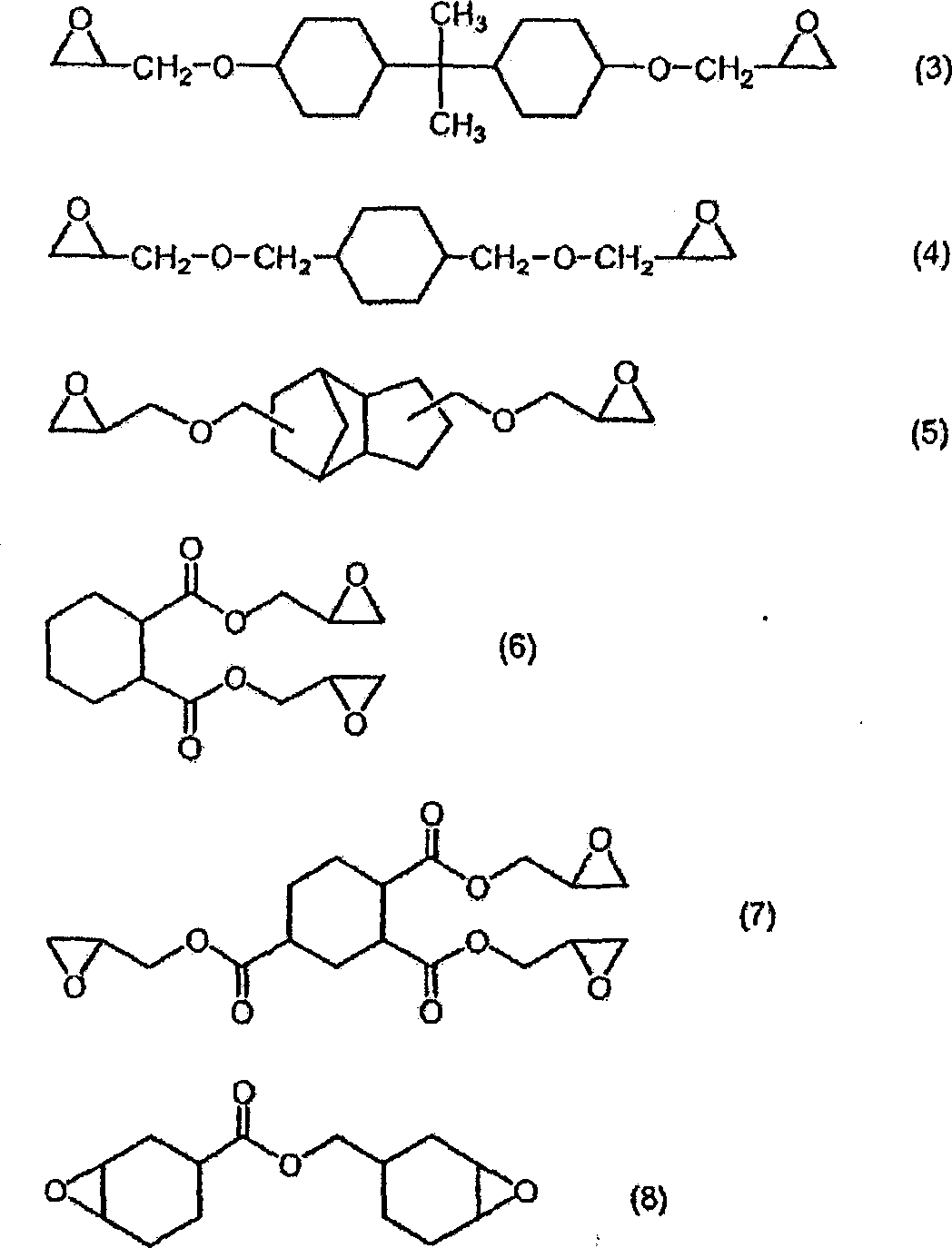

[0066] Mix epoxy resin "Adeka Resin EP-4005" (trade name, manufactured by Asahi Denka Co., Ltd.) and anhydride-based curing agent "Epoxy Resin B-570" (trade name, manufactured by Dainippon Ink Chemical Co., Ltd.), and add Conductive particle nickel particles (manufactured by Nikko Rika Co., Ltd.), so that the content of nickel particles is 75% of the curable resin composition as a whole, using a homogenizer "Selmaster one" (trade name, manufactured by Asswan Co., Ltd.), with a rotation speed of 5000rpm This was kneaded for 50 minutes to obtain a curable resin composition for forming a thermistor element layer.

[0067]

[0068] A part of the obtained curable resin composition was taken out, the resin component was removed by dissolving in acetone, and a Ni particle sample for particle diameter measurement was taken out. Using a micro-trajectory particle size distribution analyzer ("9320HRA (X-100)", trade name, manufactured by Nikkiso Co., Ltd.), the particle diam...

Embodiment 2、3 and comparative example 1、2

[0074] Except that the number of revolutions of the homogenizer when preparing the curable resin composition is the number of revolutions shown in Table 1, the others are the same as in Example 1, prepare the curable resin composition, measure the particle diameter of the Ni particles, make a thermistor and Make an evaluation. However, in Comparative Example 1, due to insufficient kneading, the curable resin composition could not be molded into a sheet shape, and a thermistor could not be produced either. Table 1 shows the particle size of the Ni particles and the room temperature resistance value of the thermistor.

reference example 1

[0076] The ratio of Ni in the curable resin composition was taken as 60% by mass, and when the curable resin composition was prepared, a stirrer ("Turned" (trade name) manufactured by AZWON Co., Ltd.) having a stirring blade was used instead of a homogenizer. Except stirring at 180 rpm for 45 minutes, a curable resin composition was prepared in the same manner as in Example 1, the particle diameter of Ni particles was measured, and a thermistor was fabricated and evaluated. Table 1 shows the particle size of the Ni particles together with the room temperature resistance value of the thermistor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com