Macromolecular thermistance element and manufacturing method thereof

A thermistor and polymer technology, applied in the field of resistance components, can solve the problem of shortened service life of polymer thermistor components, large initial resistance of polymer thermistor components, surface roughness of metal nickel-plated foil electrodes Difficulties and other problems, to achieve the effect of improving safety, reliability and service life, ingenious design, and low room temperature resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

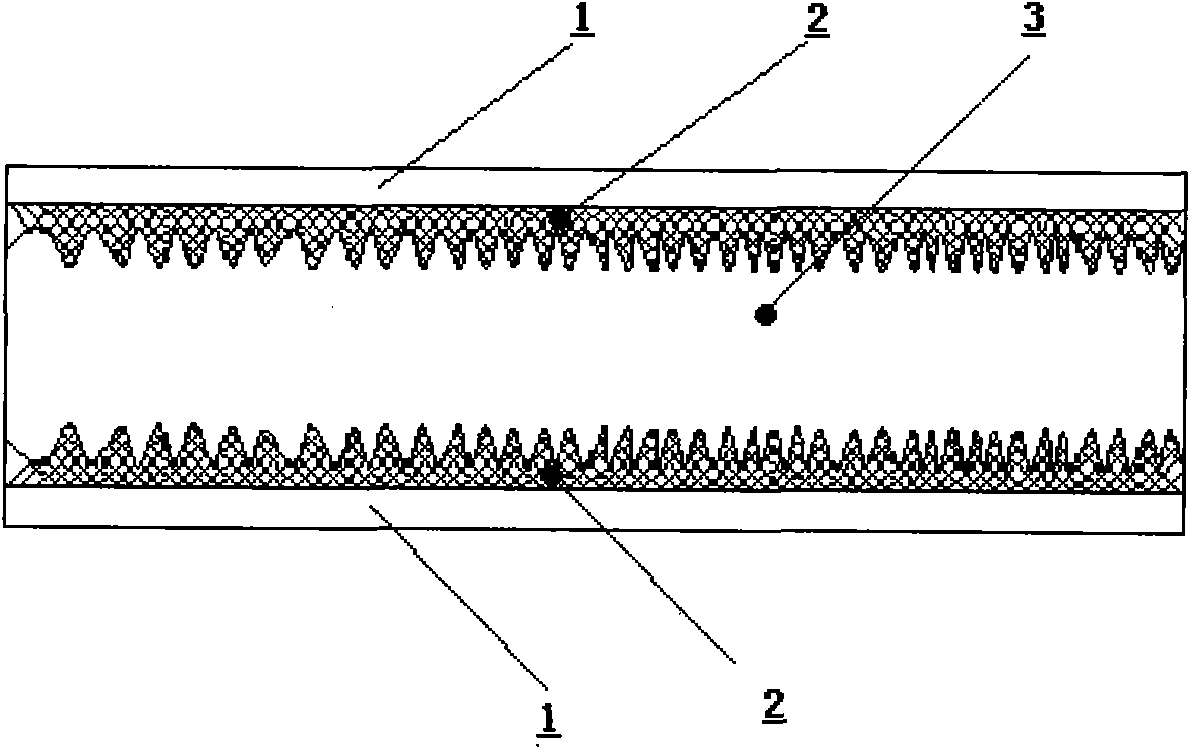

[0035] see figure 1 As shown, the polymer thermistor component of the present invention includes a PTC chip and two metal foil electrode layers 1 respectively pasted on both sides of the PTC chip, and the PTC chip includes a conductive composite material layer with a positive temperature coefficient characteristic 3 and two conductive paint layers 2 coated on both sides of the conductive composite material layer 3 respectively, and the two metal foil electrode layers 1 are pasted on the two conductive paint layers 2 respectively.

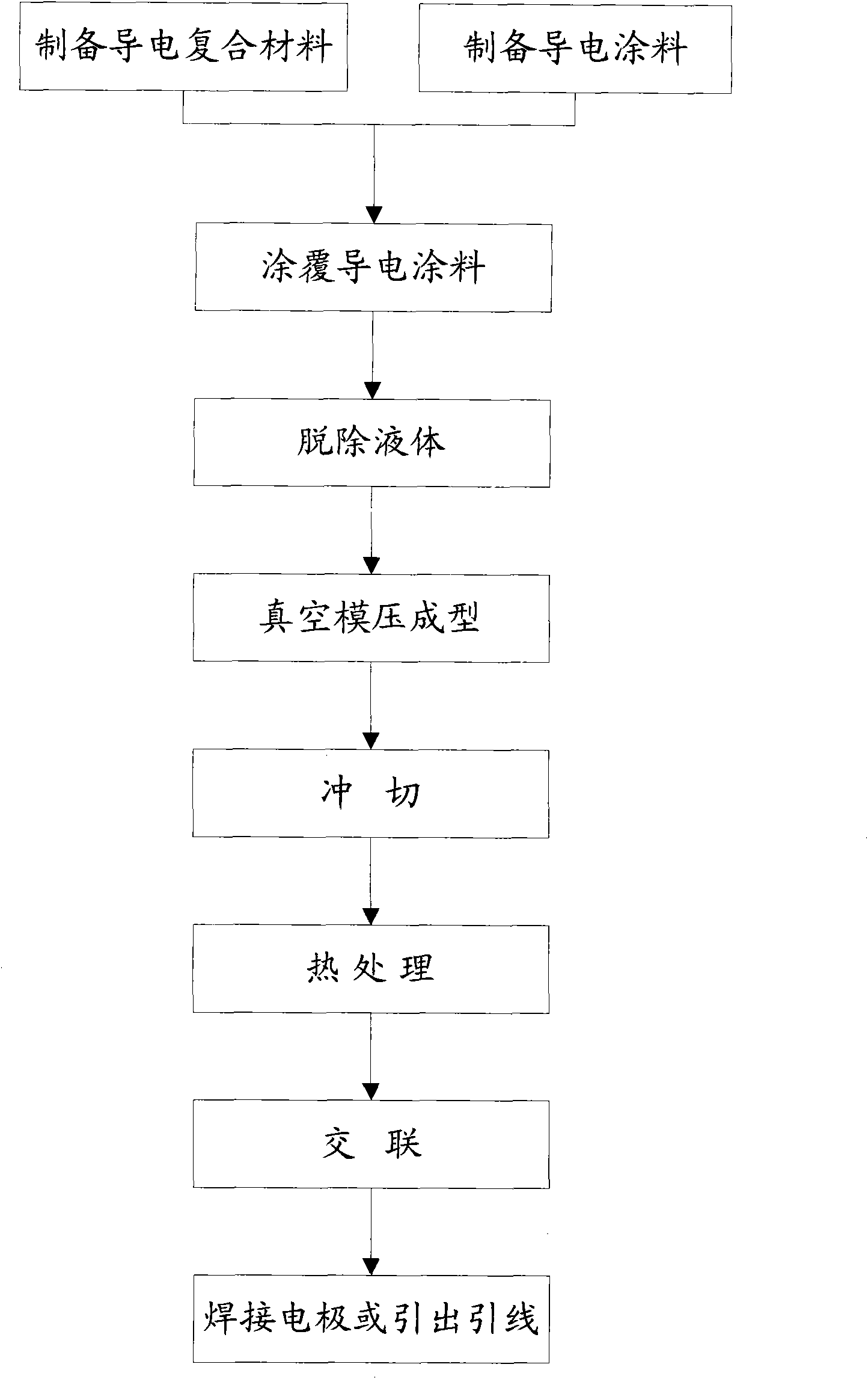

[0036] figure 2It is a flowchart of the preparation method of the polymer thermistor component used in the following examples. First prepare the conductive composite material, blend the high-density polyethylene and conductive carbon black according to the desired performance, and then hot press it into a conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com